Liquid valve of all-in-one electric water heater

A technology for electric water heaters and liquid valves, applied in fluid heaters, chemical instruments and methods, lighting and heating equipment, etc., can solve the problems of reduced service life, high labor costs, and many parts and components, so as to prolong service life and ensure Thermal efficiency, effect of avoiding fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

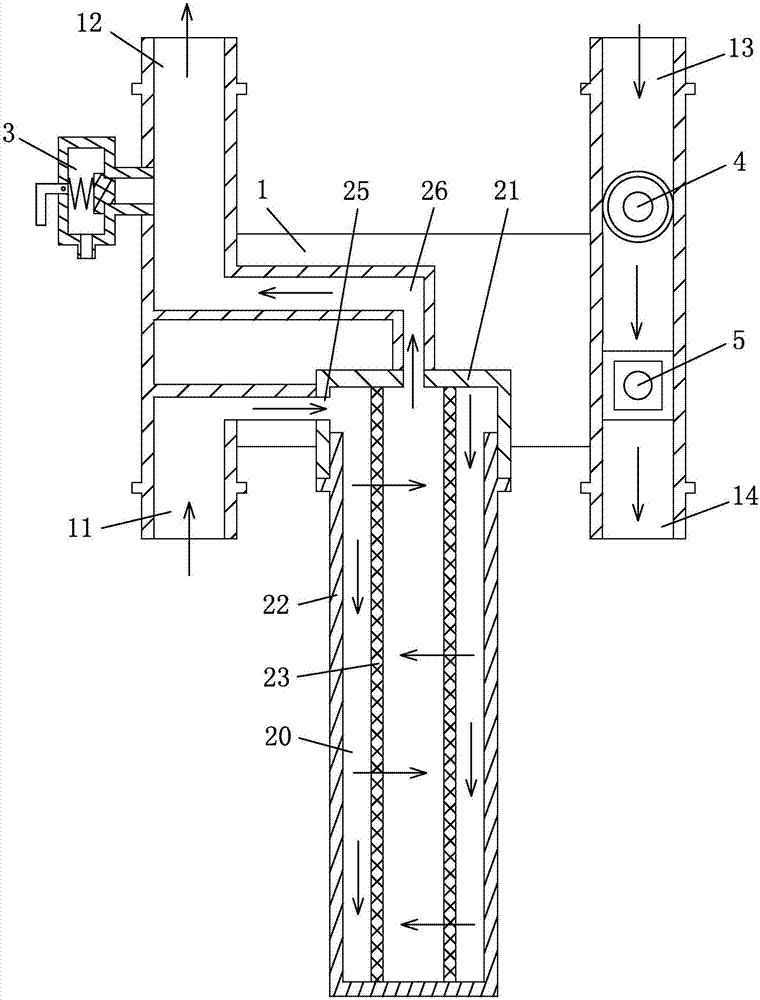

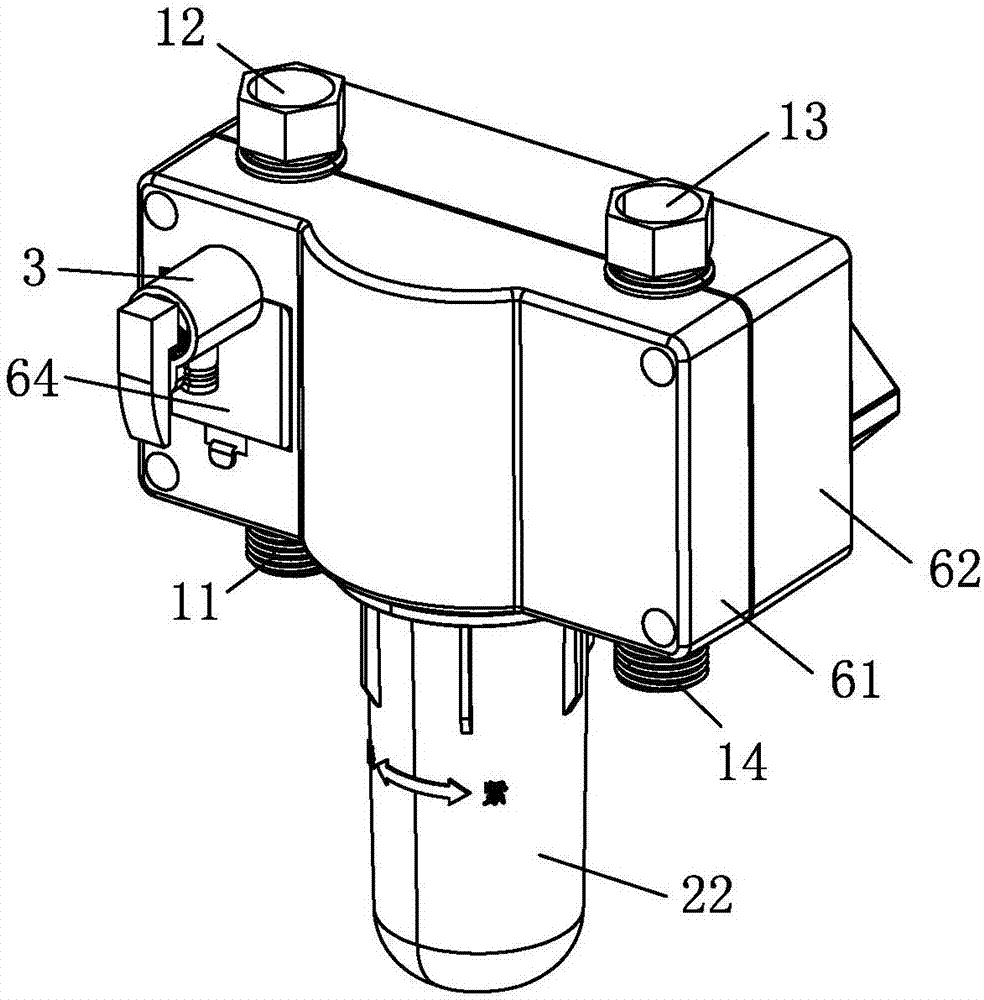

[0027] see Figure 1-Figure 5 , the all-in-one electric water heater liquid valve includes a valve body 1 with a cold water inlet pipe 11, a cold water outlet pipe 12, a hot water inlet pipe 13 and a hot water outlet pipe 14, and a water filtering device is provided on the valve body 1. The water inlet end 25 of the water filter device communicates with the cold water inlet pipe 11 , and the water outlet end 26 communicates with the cold water outlet pipe 12 .

[0028] A water filter device is installed between the cold water inlet pipe 11 and the cold water outlet pipe 12. The water is filtered before entering the water heater to reduce impurities in the water, avoid fouling of the inner tank of the water heater and the surface of the heating element, effectively prolong the service life of the water heater, and slow down the heating of the water heater. Decrease in thermal efficiency.

[0029] Further, the water filtering device includes an upper cover 21 provided with a wa...

no. 2 example

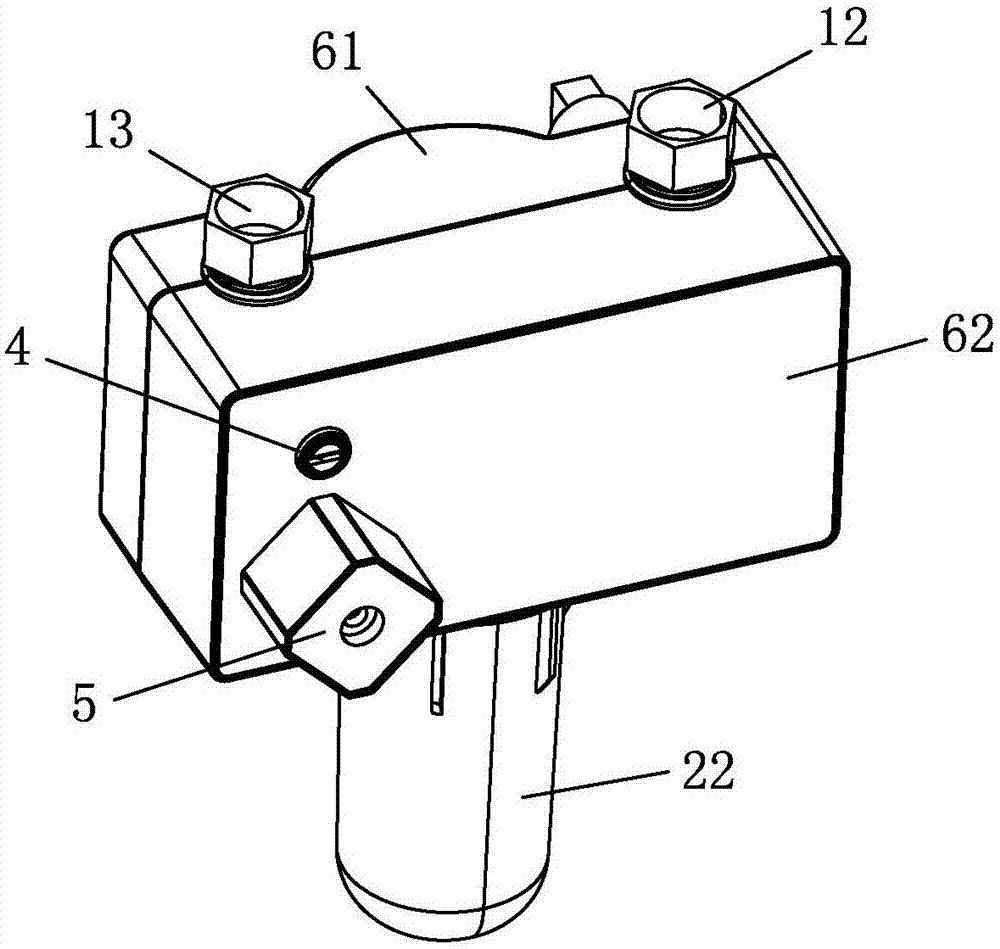

[0036] The main difference between this all-in-one electric water heater liquid valve and the first embodiment is that a bypass pipeline is provided between the cold water outlet pipe 12 and the hot water inlet pipe 13, and the cold water outlet pipe 12, hot water inlet pipe Between the water pipe 13 and the regulating valve 4, a water temperature regulating mechanism is formed to adjust the outlet temperature of the hot water outlet pipe 14 by adjusting the output flow of hot water. When the regulating valve 4 is a mechanical regulating valve, the water temperature regulating mechanism is a mechanical water temperature regulating mechanism. When the regulating valve 4 is an electronic regulating valve, the water temperature regulating mechanism is an electronic constant temperature regulating mechanism, which can be understood by those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com