Carrying machine and carrying method thereof

A transfer machine and movement technology, applied in the field of robotics, can solve the problems of uneconomical space utilization and achieve the effects of saving time, precise positioning capabilities, reducing pressure and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

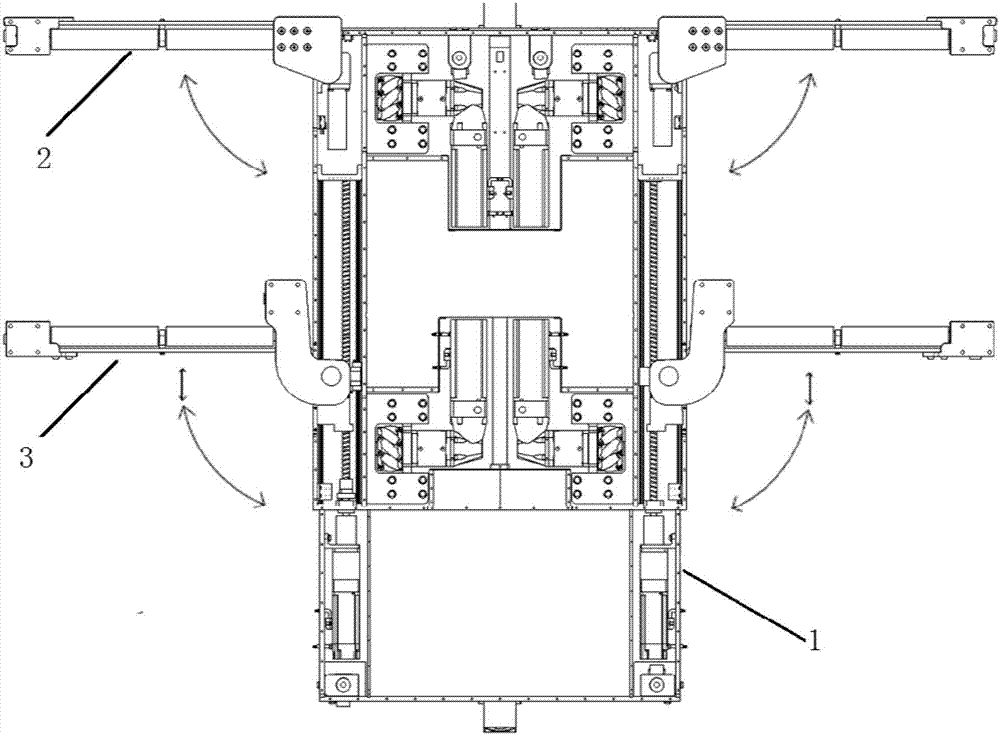

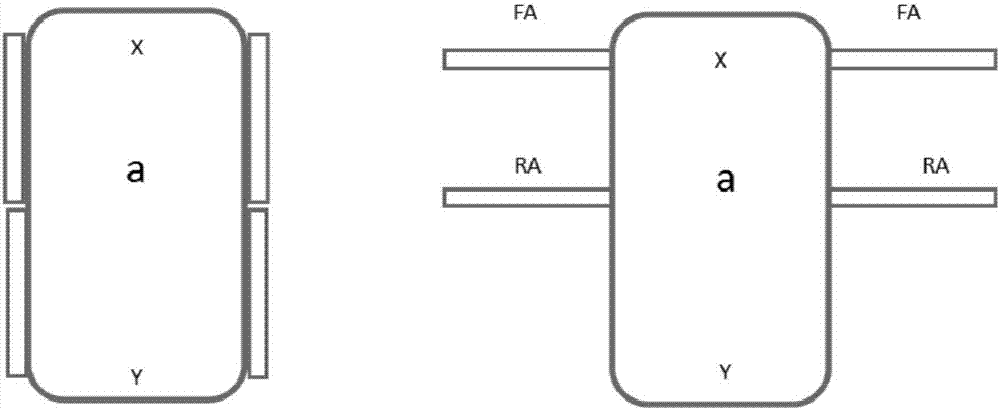

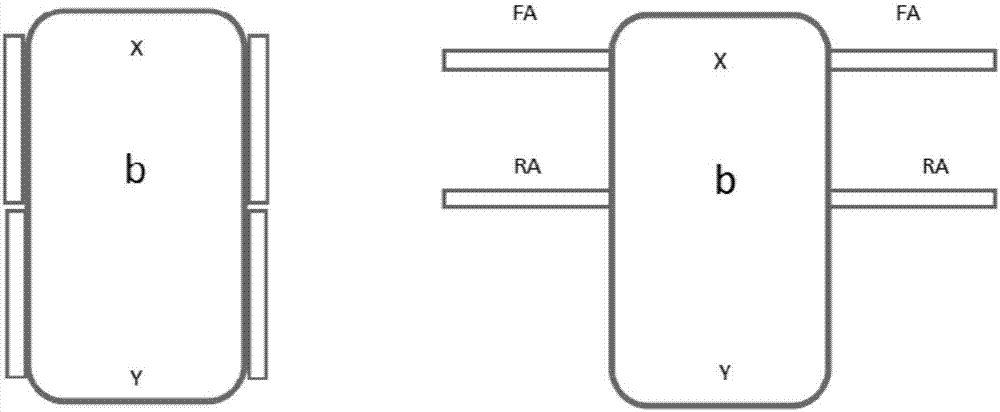

[0073] Such as figure 1 As shown, a transporter provided by the present invention includes a main frame 1, and clamping units are arranged on both sides of the main frame 1, preferably in a central axis symmetrical arrangement, and each clamping unit includes a front clamping arm 2 and a rear clamping unit. Picking arm 3, the front clamping arm 2 is a rotating mechanical arm, which is driven by a drive unit to achieve a rotational unfolding or closing movement relative to the main frame, and the rear clamping arm 3 is a combined rotation and translation mechanical arm, driven by It is driven by the unit to move along the front and rear directions of the main frame 1 and to rotate and expand or close relative to the main frame 1; both the front gripping arm 2 and the rear gripping arm 3 can be covered with friction rollers; The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com