Coal gas cooling and separating apparatus and method

A technology for cooling and separating gas, which is applied in the direction of gas dust removal, combustible gas purification, combustible gas purification/transformation, etc. It can solve the problems of inability to wash solid impurities in gas, low quenching efficiency, and many equipments, and achieve enhanced cooling and cleaning effects. Effect of improving washing cooling efficiency and reducing overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

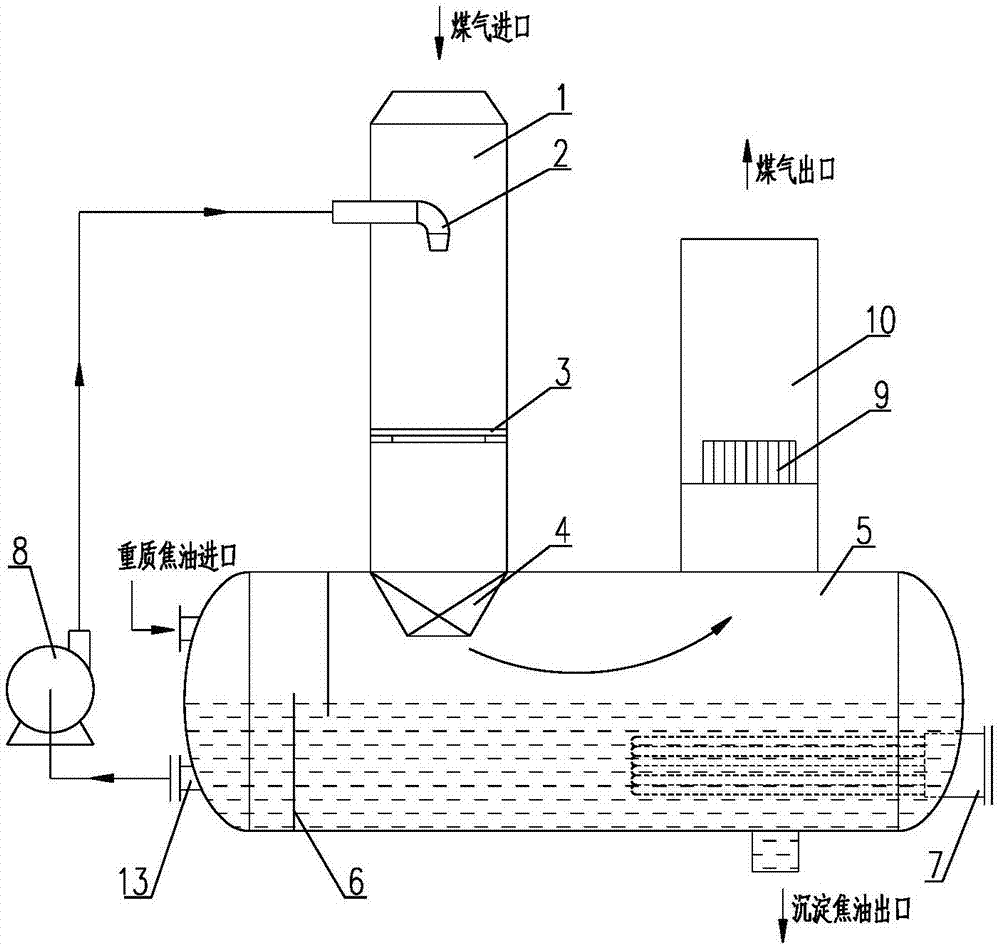

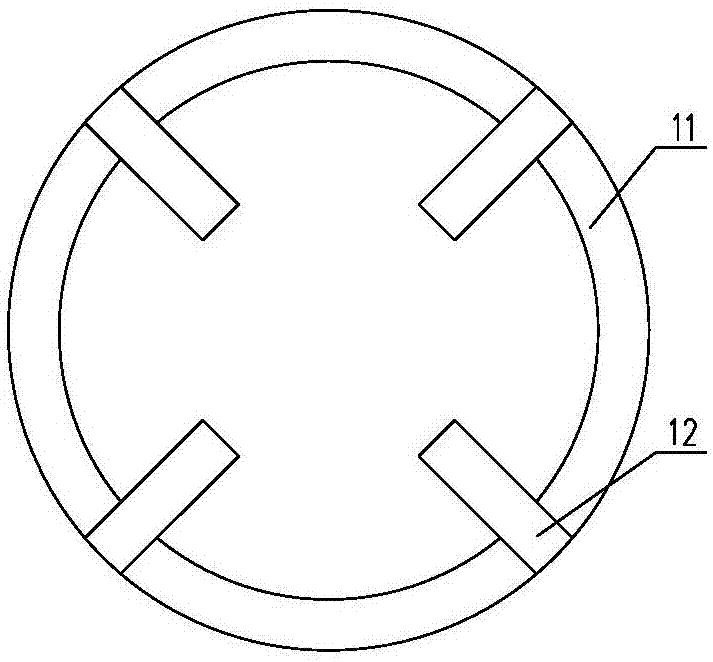

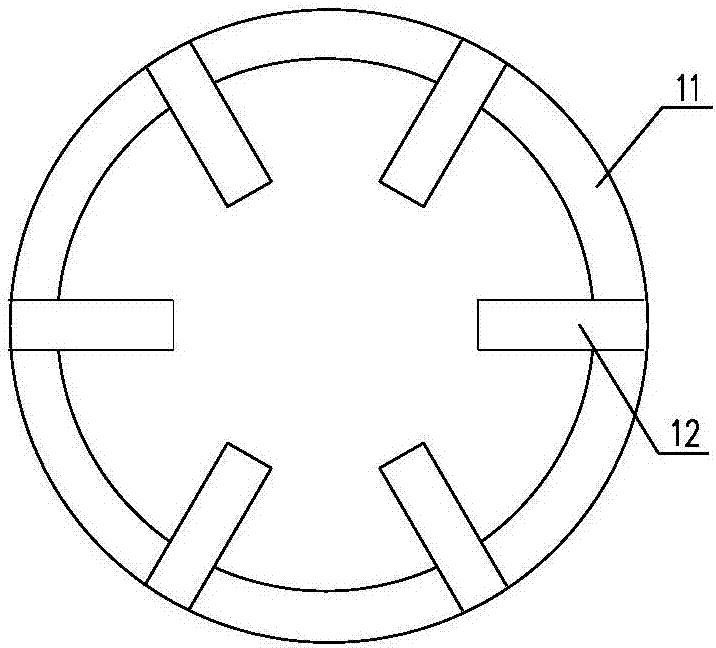

[0031] See figure 1 , gas cooling and separation device, including cooling scrubber 1, foaming element 3, gas-liquid mixer 4, tar sedimentation tank 5, tar cooler 7, cyclone separator 9, outer cylinder 10; cooling scrubber 1, tar sedimentation tank 5. The tar cooler 7 and the outer cylinder 10 are integrated structures; the tar sedimentation tank 5 is connected to the upper part of the cooling scrubber 1 through the pump 8, the bottom of the tar sedimentation tank 5 is provided with an outlet for depositing tar, and the tar sedimentation tank 5 is provided with a heavy Tar inlet; the tar sedimentation tank 5 is connected with the tar cooler 7; the top of the cooling scrubber 1 is provided with a gas inlet, the upper part is provided with a nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com