Rope-salvage-type torsion impact coring drilling tool

A technology of core drilling tools and ropes, which is applied in the direction of extracting undisturbed core devices, earth square drilling, and vibration drilling, etc. It can solve problems such as stick-slip vibration, reduce core blockage, reduce auxiliary operation time, and improve rock breaking efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

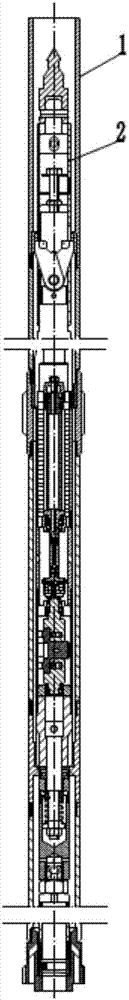

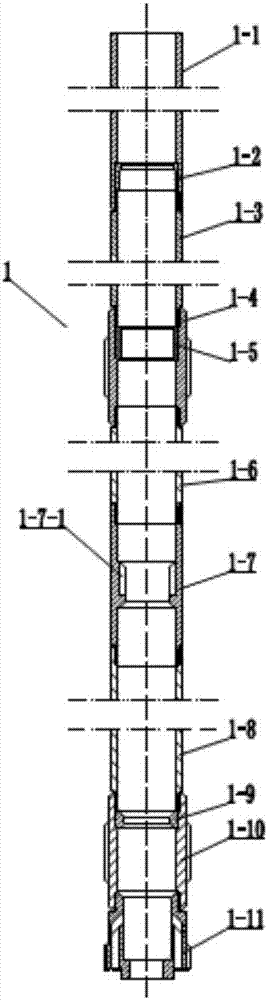

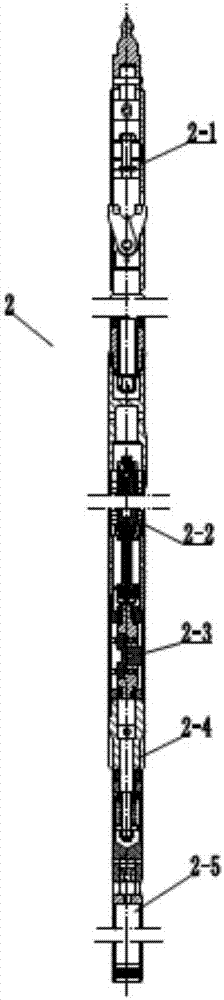

[0039] see figure 1 , figure 2, the present invention provides a rope salvage torsional percussion core drilling tool, which includes an outer tube assembly 1 and an inner tube assembly 2; the inner tube assembly 2 is set in the cavity of the outer tube assembly 1. Wherein the outer pipe assembly 1 is sequentially composed of an upper connecting pipe 1-1, a bullet stopper 1-2, an upper outer pipe 1-3, an upper reamer 1-4, a water blocking ring 1-5, a middle and outer pipe 1-6, twisting joint 1-7, lower outer tube 1-8, centering ring 1-9, lower reamer 1-10 and drill bit 1-11 are connected by thread; In the inner cavity of the connecting pipe 1-1, and tighten the thread of the upper connecting pipe 1-1 and the upper outer pipe 1-3 to limit the position; the water blocking ring 1-5 is embedded in the inner cavity of the upper reamer 1-4 , whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com