Tunnel brick used for engineering construction

A technology for construction and tunnel bricks, which is applied in tunnels, tunnel linings, shaft linings, etc., to achieve the effects of simple tunnel brick structure, convenient and stable stacking, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

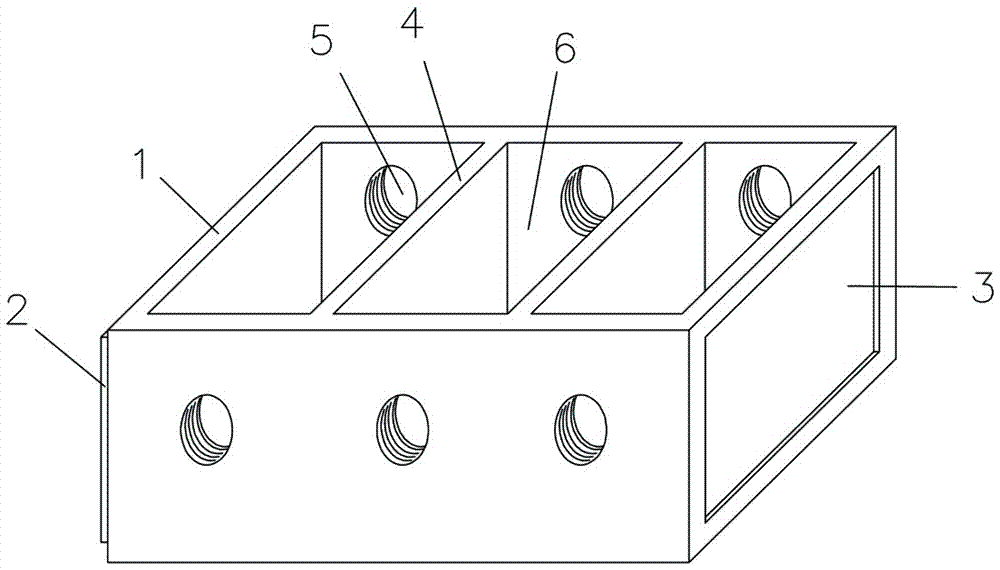

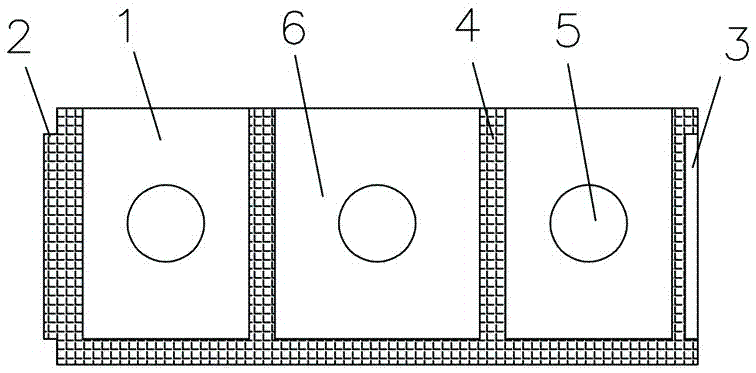

[0023] Example 1, such as Figure 1-2 Shown:

[0024] A tunnel brick for engineering construction, the upper part of the brick body 1 of the tunnel brick is provided with several partitions 4, and the partitions 4 separate the tunnel brick into several grooves 6 with the same size; the front of the groove 6 The wall and the rear wall are symmetrically provided with screw holes 5 for threaded connection between the upper and lower tunnel brick structures; the left side of the brick body 1 is provided with a side convex 2 structure, and the right side of the brick body 1 is provided with a The undercut 3 structure matched with the side convex 2 is used for the lateral fitting connection between the left and right adjacent spliced tunnel bricks; the material of the brick body 1 is a mixture of fly ash and concrete.

[0025] In one aspect of the present invention, through the improved design of the tunnel brick structure, the tunnel brick can be used as a reinforcing rib struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side wall thickness | aaaaa | aaaaa |

| Width size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com