Plug-in type three-way normally-closed hydraulic-control reducing valve

A cartridge-type, pressure-reducing valve technology, applied in the field of hydraulic control valves, can solve the problems of simple and fast control of pressure-reducing valves and high manufacturing costs, and achieve compact structure, improved safety, and high pressure regulation range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples of specific implementation, but the embodiments should not be interpreted in a limiting manner, and the detailed description of the non-limiting embodiments done in conjunction with the accompanying drawings can make the The technical features, purpose and advantages of the invention will become more obvious.

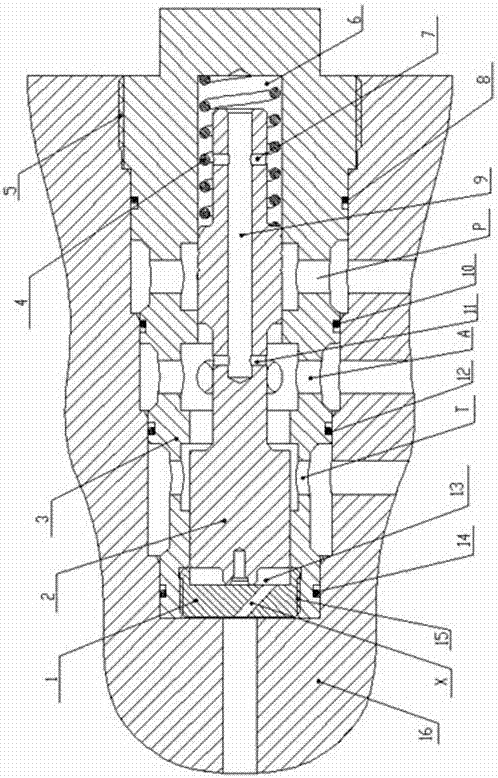

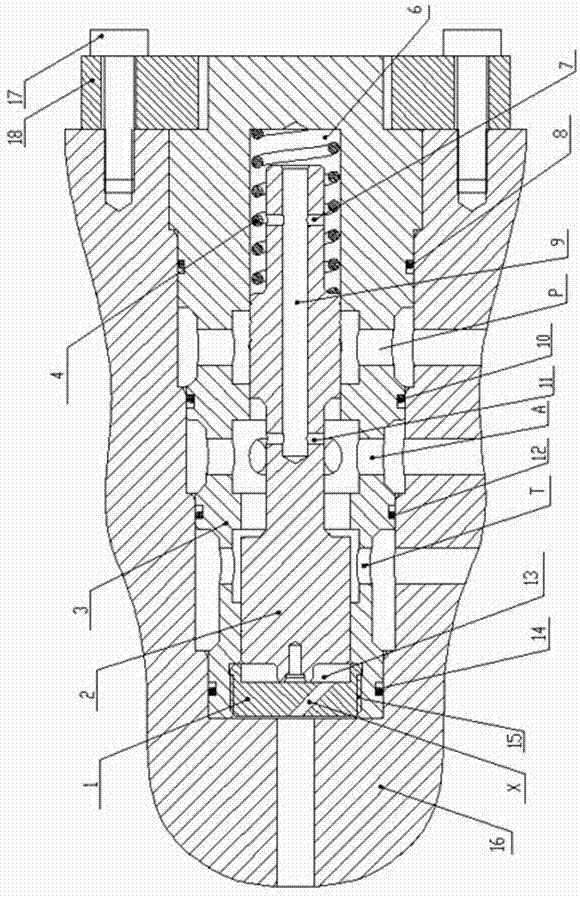

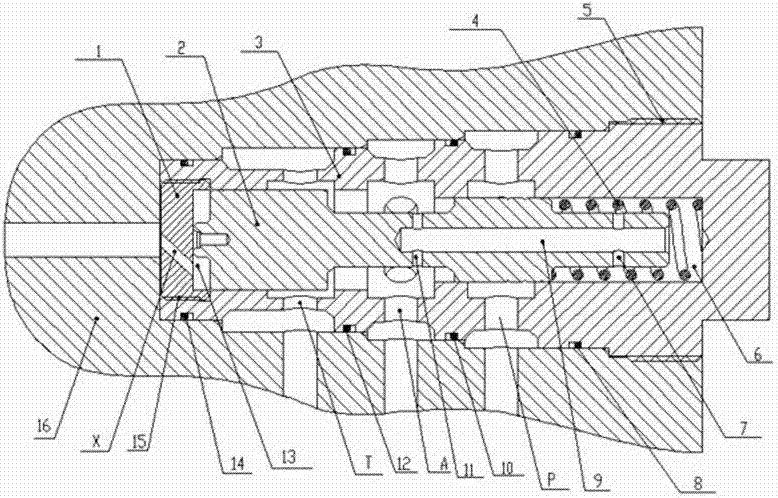

[0021] figure 1 Shown is a schematic structural view of the valve body 3 being installed on the external device 16 in a threaded form, from figure 1 It can be seen from the figure that the present invention contains three working windows of retaining ring 1, spool 2, valve body 3, spring 4, inlet P, outlet A, oil return port T and a window for control---control port X , the outlet A is located between the inlet P and the oil return port T, the valve core 2, the retaining ring 1 and the valve body 3 form the control chamber 13, the control ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com