Reactive free radical generation system and working method thereof

A technology for generating systems and free radicals, applied in separation methods, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of increasing energy consumption and production costs, unable to produce active free radical oxidation effects, and narrow application scope and other problems, to achieve the effect of simple design, convenient use and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

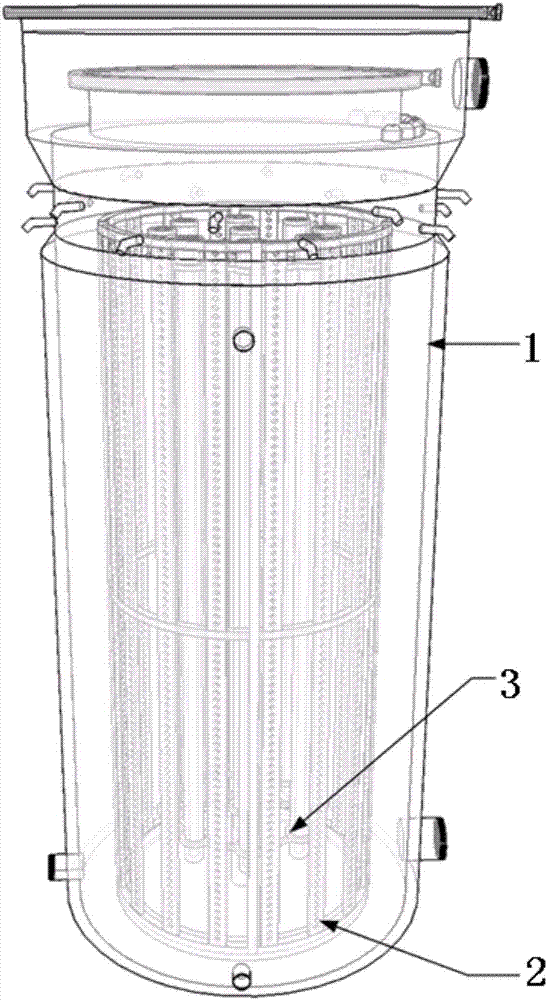

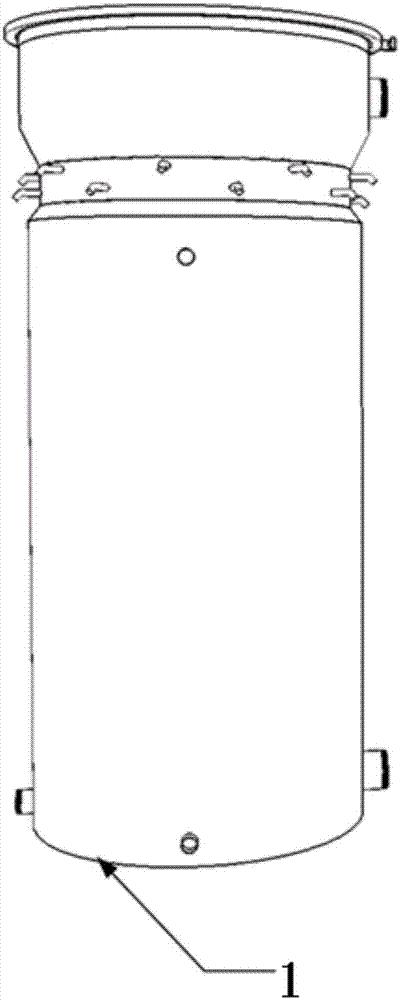

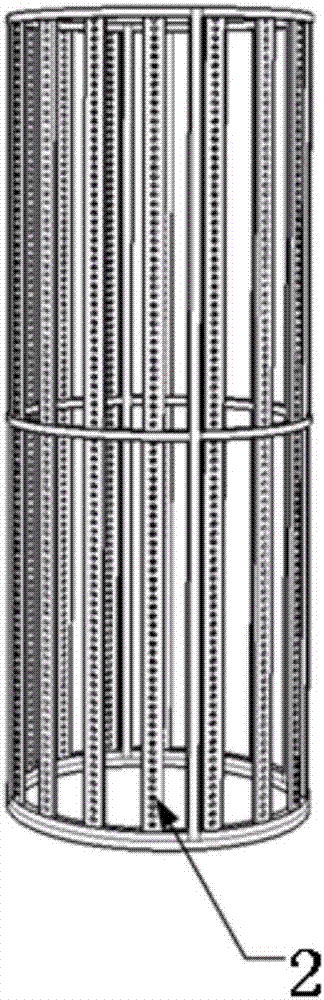

[0071] Example 1: figure 1 It is an embodiment of an active free radical generating system of the present invention, which includes: a main reaction chamber 1, an internal catalyst carrier system 2, installed in a cylindrical design structure composed of a catalyst carrier rod and a frame, and an ultraviolet lamp system 3. Comprising UV lamps 3.2 and a support for each lamp. The internal components of the ultraviolet lamp 3.2 (see FIG. 5 ) as shown in the drawings and accompanying drawings do not belong to the present invention, but are only used to demonstrate how this embodiment is used for fixing ultraviolet lamps and other similar lamps. The design of the present invention is shown as cylindrical, but it can also be designed as square, or hexagonal, and any other shape, and is not limited to cylindrical, square and hexagonal. The size, length, thickness and quantity contained in this embodiment can be changed according to actual needs.

[0072] Figure 2-1 , Figure 2-...

Embodiment 2

[0080] Example 2: Figure 7 It is the second embodiment of an active free radical generating system of the present invention. The ultraviolet lamp 3.2 is placed in the quartz tube 3.3, and the quartz tube 3.3 is installed in the main reaction chamber 1 for exciting and generating free radicals in the reaction chamber. The quartz tube 3.3 is made of quartz that can transmit 100% ultraviolet light to ensure the maximum effect of the light. There is an inlet 1.4 at the bottom of the present invention, which is used for ozone or other gases required for free radical generation reactions. There is a gas outlet 1.5 at the top of the main reaction chamber 1, which is used to release free radicals and gases generated by the reaction. The schematic design shows one exit, but multiple exits can be designed upon request. This outlet has an in-line check valve 1.5.1 to prevent back flow of gas or liquid. Figure 7 Also shown is a protective cover 1.11 on the top, which is used to prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com