Balanced vertical-axis large wind power generation unit

A wind turbine, vertical axis technology, applied to wind turbine components, wind motor combinations, wind engines, etc., can solve problems such as increased cost, small starting torque, skewed blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

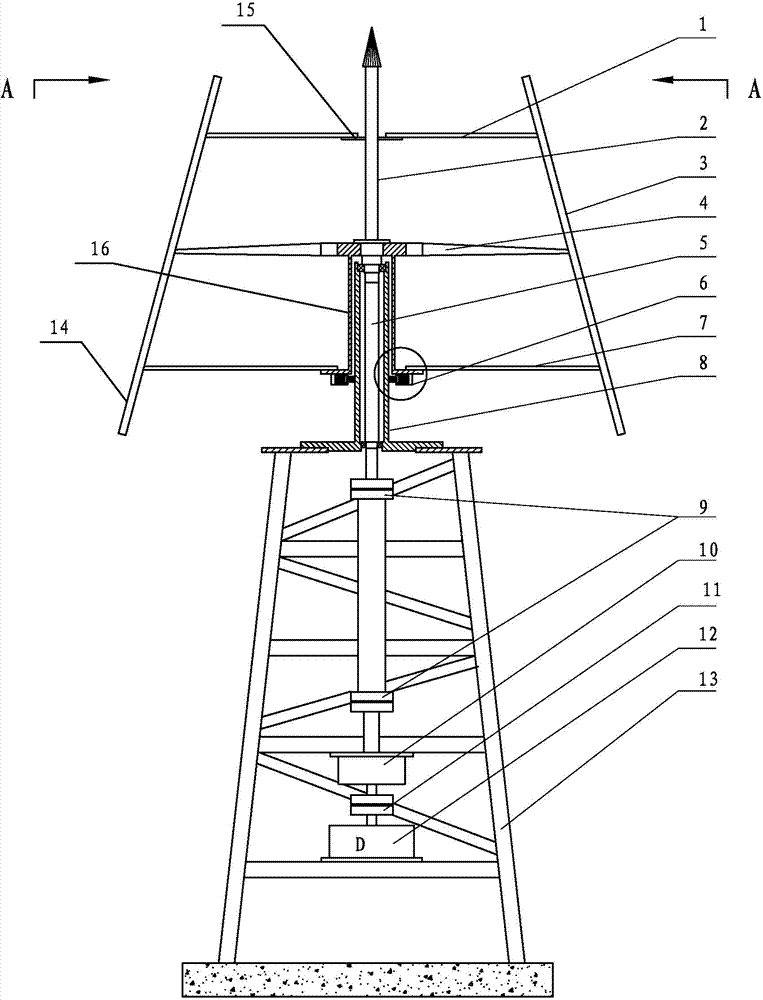

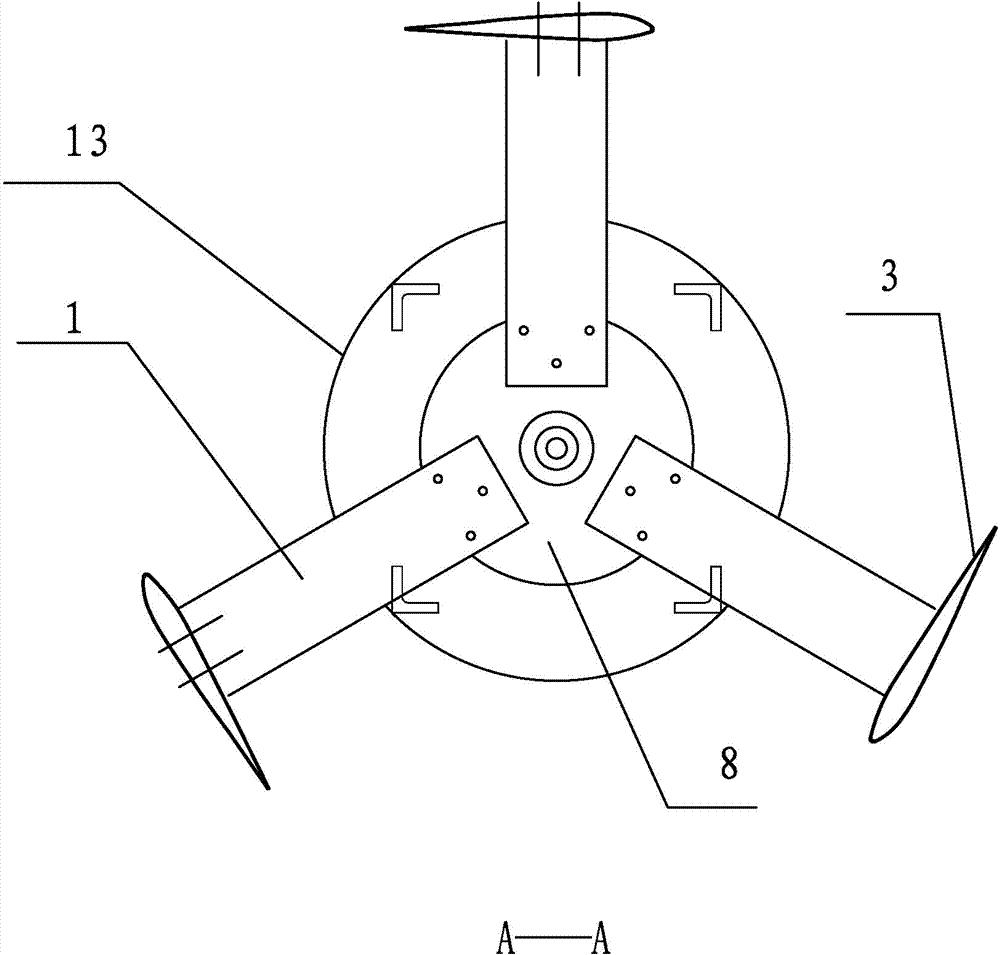

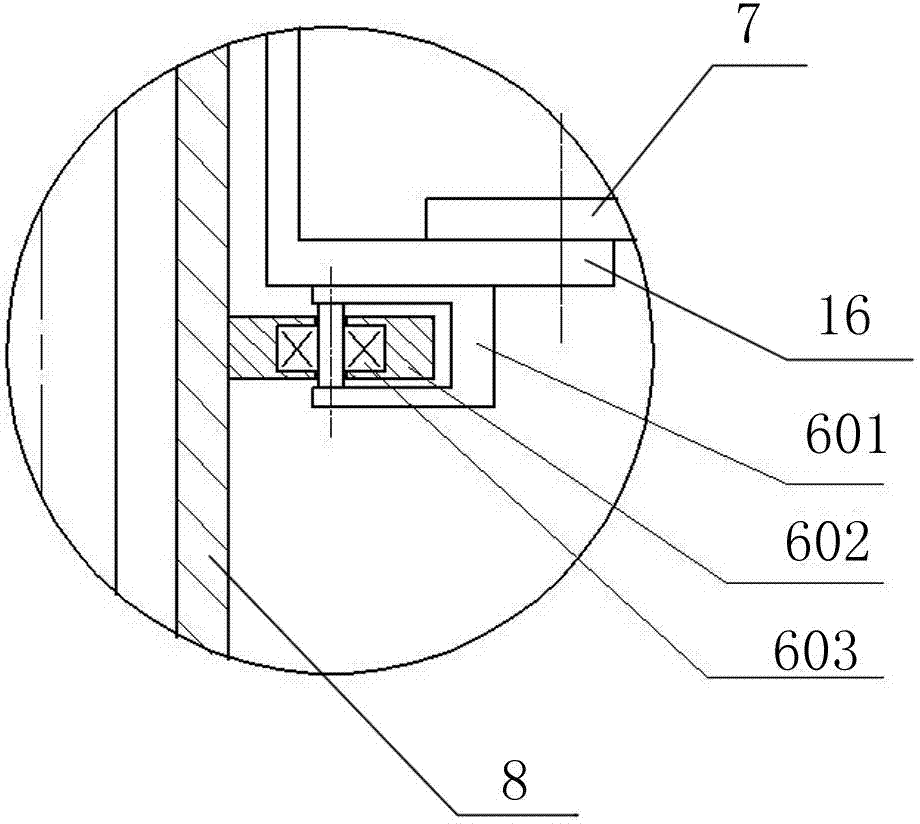

[0050] A kind of balanced type vertical axis large-scale wind power generating set of the present invention, such as figure 1 with figure 2 As shown, it includes a permanent magnet generator 12 and a blade drive assembly. The blade drive assembly includes a wind rotor group and a vertical vertical axis rotation system. The wind rotor group is provided with two or more lift-type blades 3 and corresponding Two or more sets of blade supports are provided, and the blade supports include an upper support 1, a middle support 4 and a lower support 7, wherein:

[0051] The vertical vertical axis rotation system is provided with an upper column 2, a lower column 8 and a central rotary axis mechanism;

[0052] The central rotary shaft mechanism is provided with a central shaft 5 and a universal coupling 9. The central shaft 5 is supported in the lower column 8 through bearing support, and the upper end of the central shaft 5 is connected with the upper column 2, and the lower end of t...

Embodiment 2

[0065] A kind of balanced type vertical axis wind power generating set of the present invention, as figure 1 As shown, the main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that: the upper and / or lower parts of the lift blades 3 are provided with extensions 14 . The top and / or the bottom of the lift type blade 3 all increase the extension 14, which can improve the wind-bearing area of the lift type blade 3 and improve the power generation efficiency. Especially the bottom of the lift type blade 3 is provided with an extension 14, which can make the lift The center of gravity of the type blade 3 is lowered, which effectively improves the anti-swing capability of the wind power generating set and makes the operation more stable.

[0066] Specifically, both the upper...

Embodiment 3

[0070] A kind of balanced type vertical axis wind power generating set of the present invention, as figure 1 As shown, the main technical solution of this embodiment is basically the same as that of Embodiment 1 or Embodiment 2, and the features not explained in this embodiment are explained in Embodiment 1 or Embodiment 2, and will not be repeated here. . The difference between this embodiment and embodiment 1 or embodiment 2 is that the thickness of the middle bracket 4 is greater than or equal to the thickness of the upper bracket 1 and / or the thickness of the lower bracket 7 .

[0071] Specifically, the thickness of the upper bracket 1 and the thickness of the lower bracket 7 can be set to be the same, and the thickness of the middle bracket 4 is set to be 1.5 to 2.5 times the thickness of the upper bracket 1 or the thickness of the lower bracket 7 . Since the middle bracket 4 plays a major load-bearing role, the thicker thickness of the middle bracket 4 can make the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com