Flange connection device

A connecting device and flange technology, which is applied to flange connections, pipes/pipe joints/fittings, passing components, etc., can solve the problems of collapse, low efficiency of single pipeline fluid delivery, etc., and achieve stable and reliable connections and wide application range Extensive, guarantee the effect of pressure bearing capacity and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

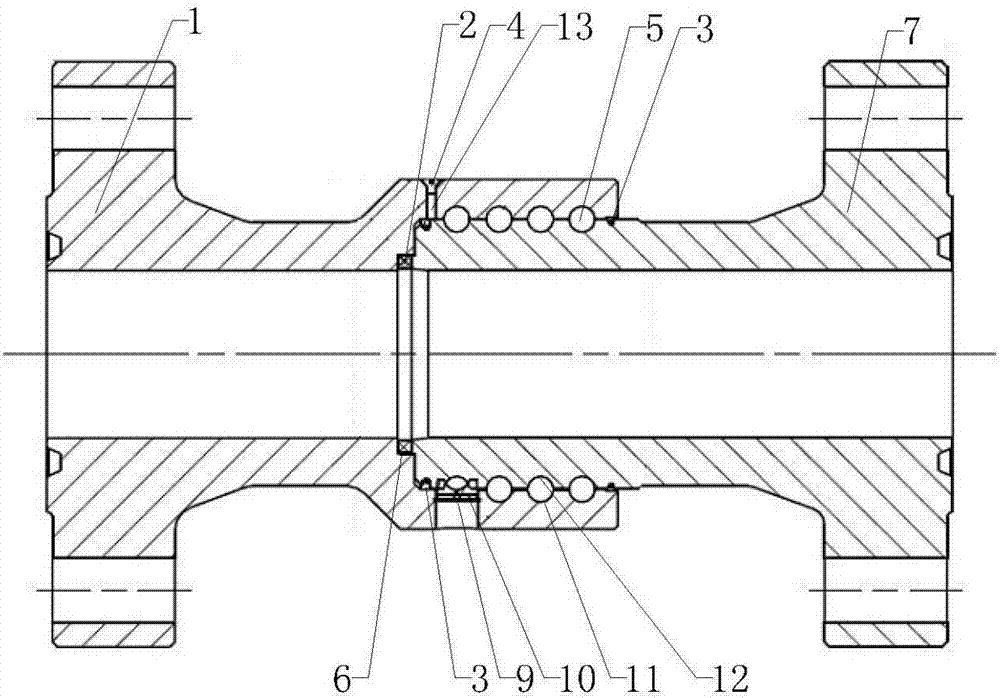

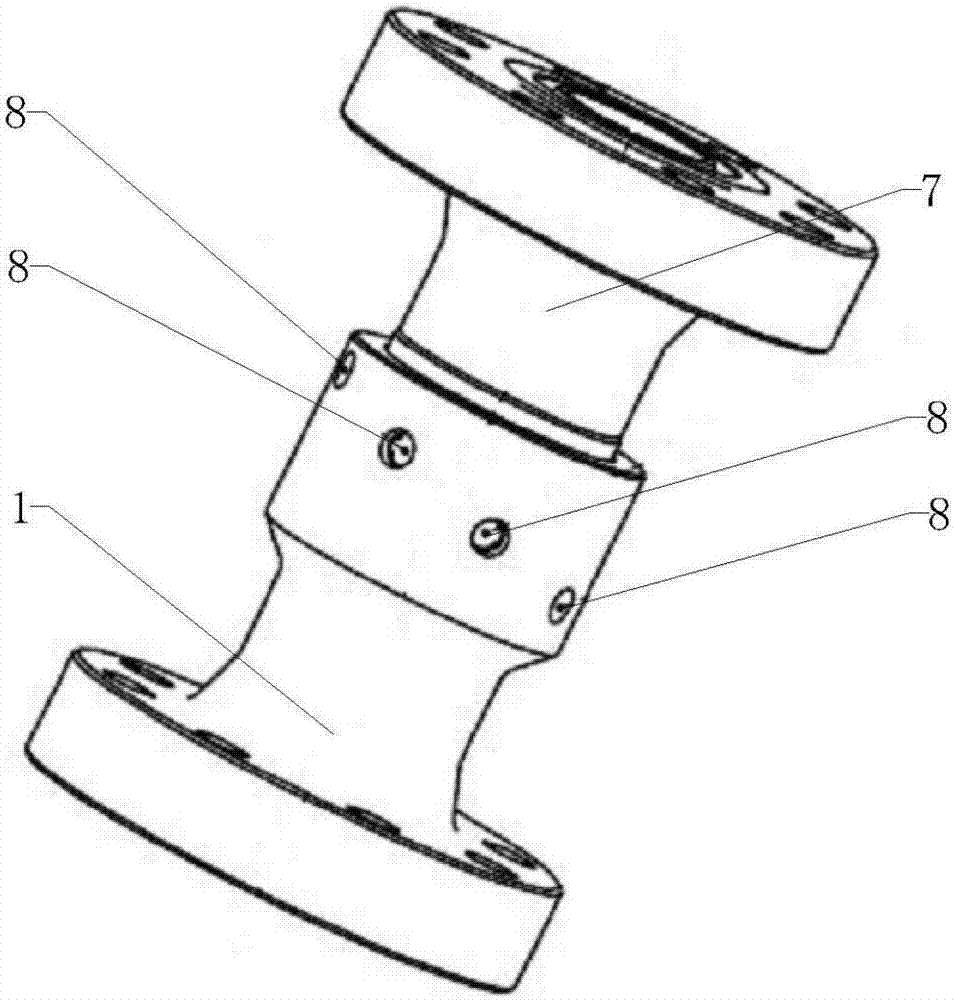

[0031] Example: as attached Figure 1-2 As shown, a flange connection device includes a first joint 1 and a second joint 7, the first joint 1 is connected to the second joint 7, and a rolling joint is provided between the first joint 1 and the second joint 7 device, the first joint 1 and the second joint 7 can freely rotate 360 degrees around the central axis. The first joint 1 and the second joint 7 can be selected in various forms, such as direct joints or bent joints, and the first joint 1 and the second joint 7 can be provided with connecting flanges, and the connecting flanges can be connected through corresponding Bolts and other devices are connected to each other.

[0032] The second joint 7 is sleeved in the first joint 1, the inner cavity of the first joint 1 is connected to the inner cavity of the second joint 7, and the rolling device is connected with the first joint 1 and the second joint 7. connect.

[0033] The rolling device includes a first groove 11 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com