A Performance Simulation Method of Vehicle Hydraulic Shock Absorber

A technology of hydraulic shock absorber and simulation method, which is applied in the field of hydraulic shock absorber, and can solve the problems of lack of simulation ability, high standard of shock absorber piston and valve size, and limited application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

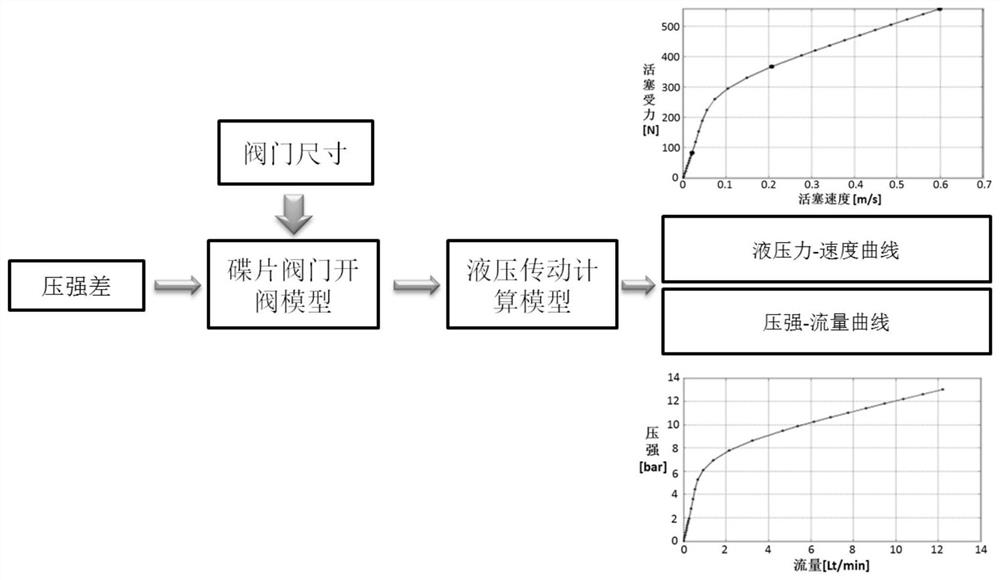

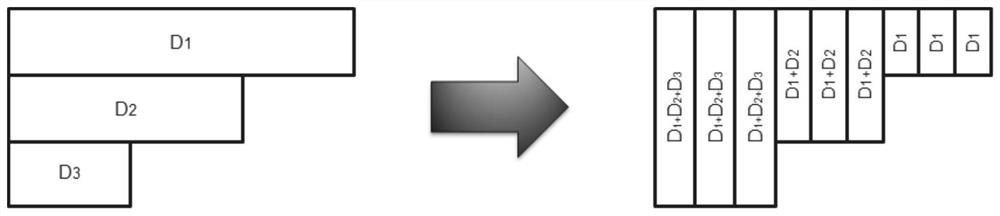

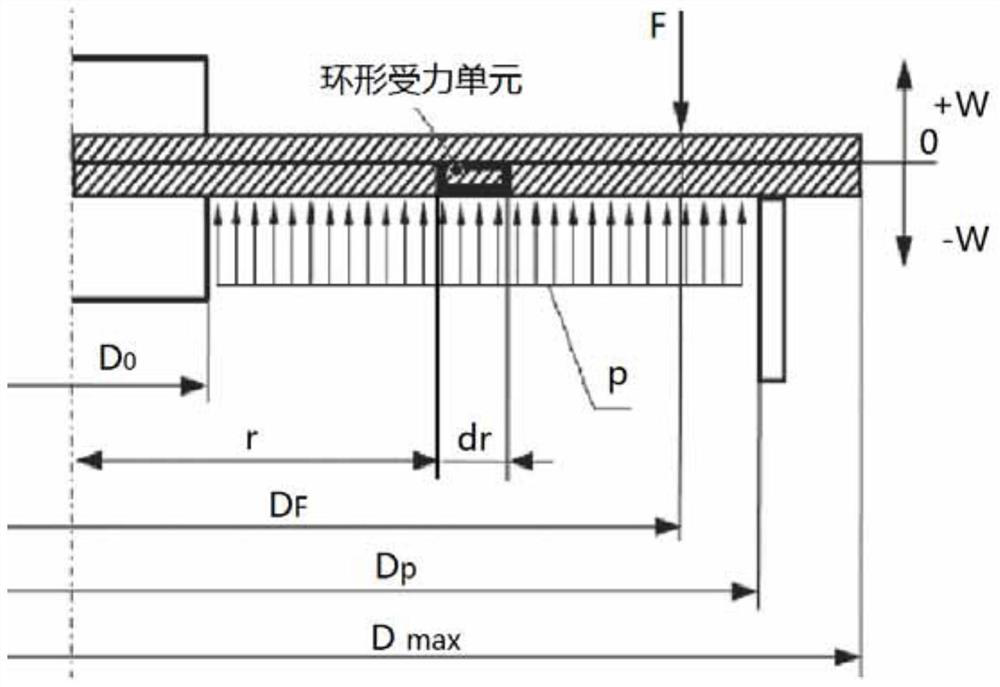

[0088] The invention discloses a performance simulation method of a vehicle-mounted hydraulic shock absorber, wherein the valve in the vehicle-mounted hydraulic shock absorber is a piston with a disc-shaped valve plate and a throttle, that is, the entire valve channel includes the throttle and the channel after the valve is opened, such as figure 1 As shown, based on MATLAB software, for valves with different channel cross-section types and sizes, the disc valve opening model is established based on the fluid mechanics theory, and the valve opening degree of the piston valve is obtained through the disc valve opening model, and then the on-board hydraulic reducing The calculation model of the hydraulic transmission between the cavities of the shock absorber is used to calculate the pressure loss caused by the friction between the fluid and the channel, the pressure loss caused by the narrowing of the fluid inflow channel, the pressure loss caused by the widening of the fluid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com