Sorting machine system with automatic identifying function and large sorting scope

An automatic identification and sorting machine technology, applied in sorting and other directions, can solve the problems of limited working range and high cost of industrial robots, and achieve the effects of fast movement, enlarged sorting range and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

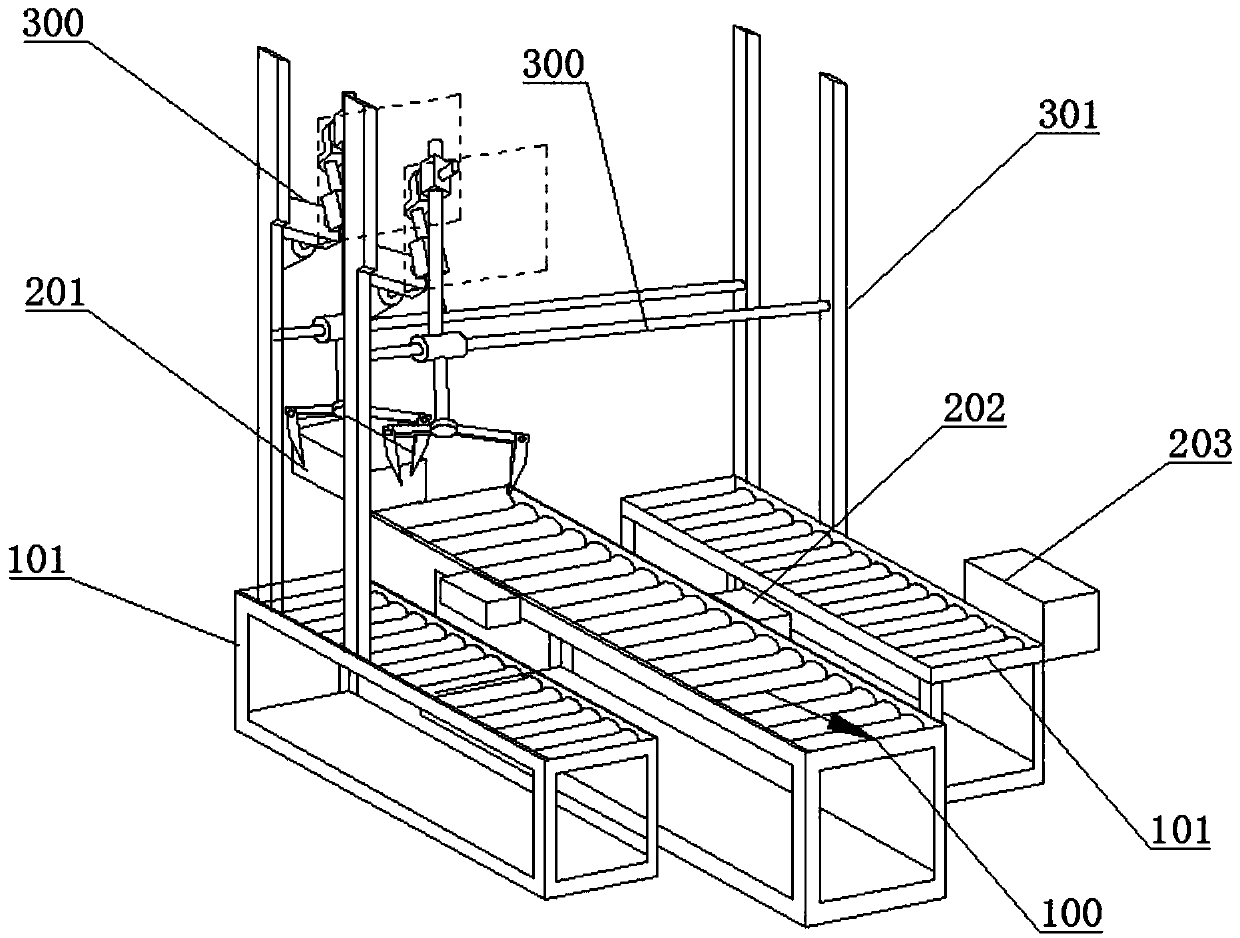

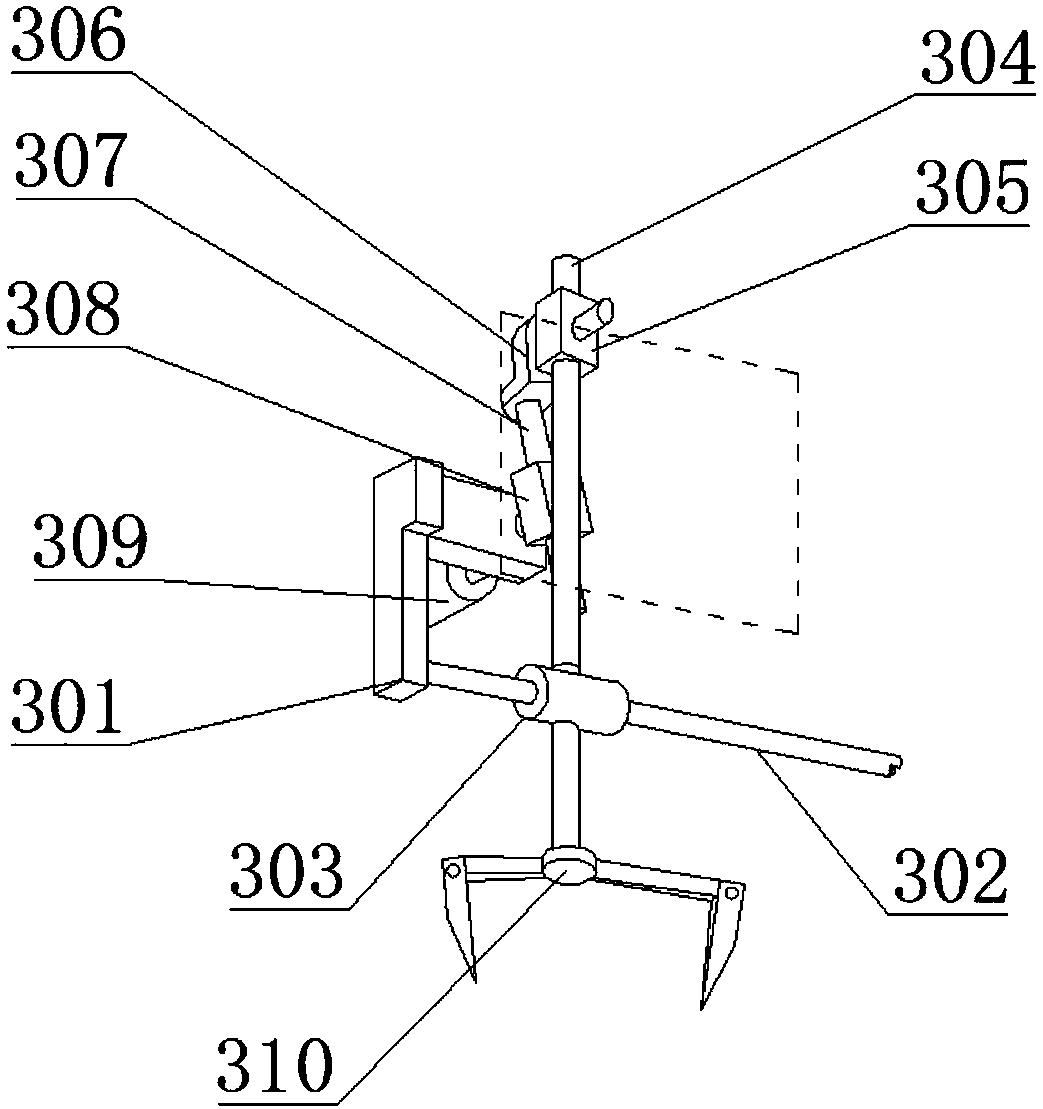

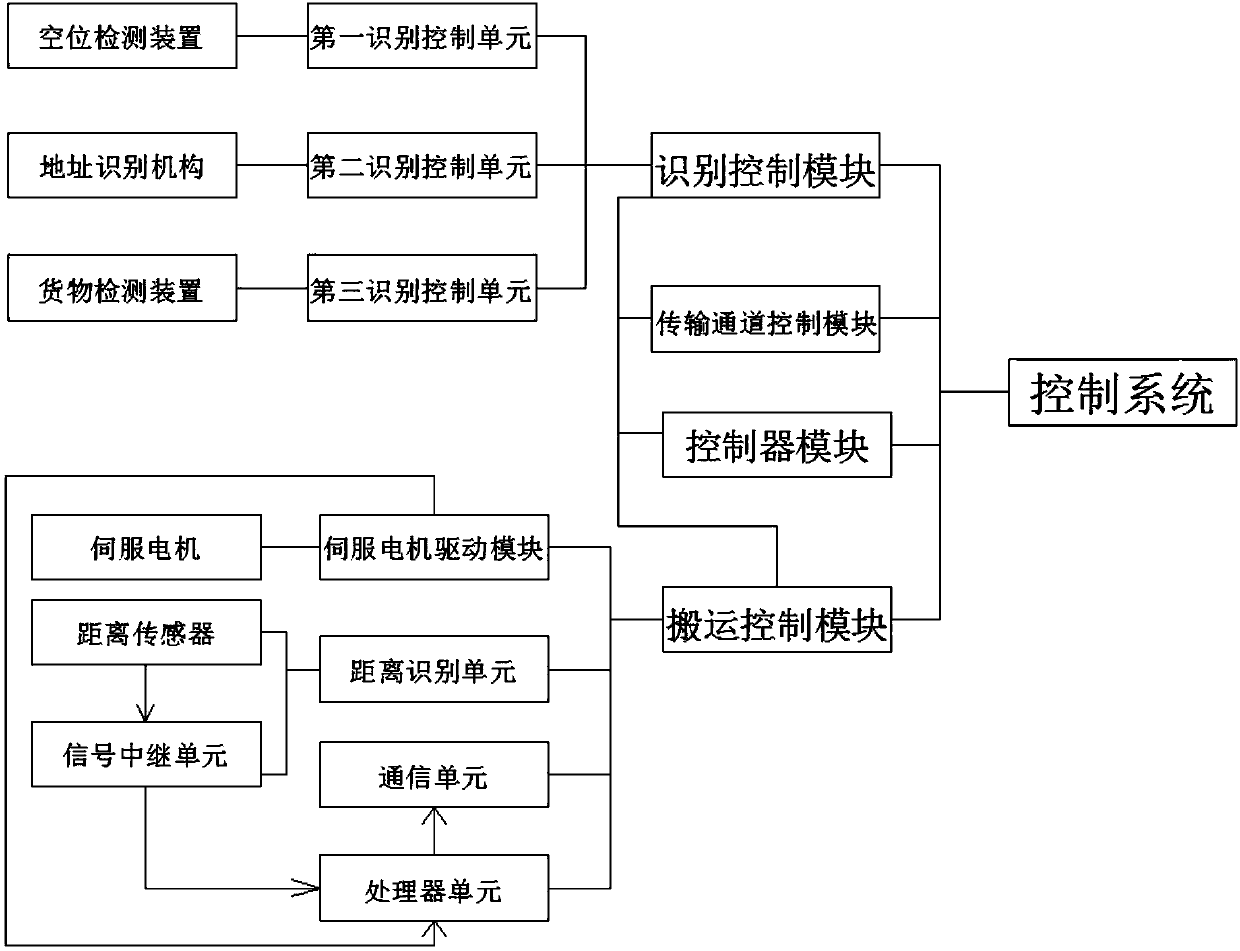

[0040] A sorter system with automatic identification and a large sorting range, including a transmission channel 100, the transmission channel 100 is provided with an identification mechanism 200, a handling mechanism 300 along the product conveying direction, and a control system, the transmission channel 100, and the identification mechanism 200 1. The transfer mechanism 300 is electrically connected with the control system, and the transfer channel 100 is also connected with the sorting channel 101. The transfer mechanism 300 includes a frame 301 arranged on the transfer channel 100, and the frame 301 is provided with a transfer assembly. The track shaft 302 on the frame, the track shaft 302 is sleeved with a sliding base 303, the sliding base 303 is connected with a mechanical claw assembly 310, the sliding base 303 is provided with a connecting rod 304, and the connecting rod 304 is sleeved with a middle slide block 305, the middle slider 305 is hinged with a joint 306, th...

Embodiment 2

[0043] Based on the first embodiment, a linear bearing is provided between the sliding base 303 and the track axis 302 .

[0044] In this embodiment, a linear bearing is provided between the sliding base 303 and the track axis 302, so that the sliding base 303 moves on the track axis 302 more quickly and smoothly, and the product moves more smoothly.

Embodiment 3

[0046] On the basis of the first embodiment, the two ends of the track axis 302 are sleeved with buffer pads.

[0047] In this embodiment, the two ends of the track axis 302 are provided with buffer pads. When the sliding base 303 is sorted in place, the buffer pad absorbs the kinetic energy of the sliding base 303, reduces the movement speed of the sliding base 303, and prevents the sliding base 303 from damaging the frame. 301, also avoid the product falling off under severe vibration when in place.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com