Servo cable cutting machine and cable conveying device thereof

A transmission device and cable technology, which is applied in the field of wire and cable cutting equipment, can solve the problems of reducing work efficiency and inability to adapt cables, and achieve the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

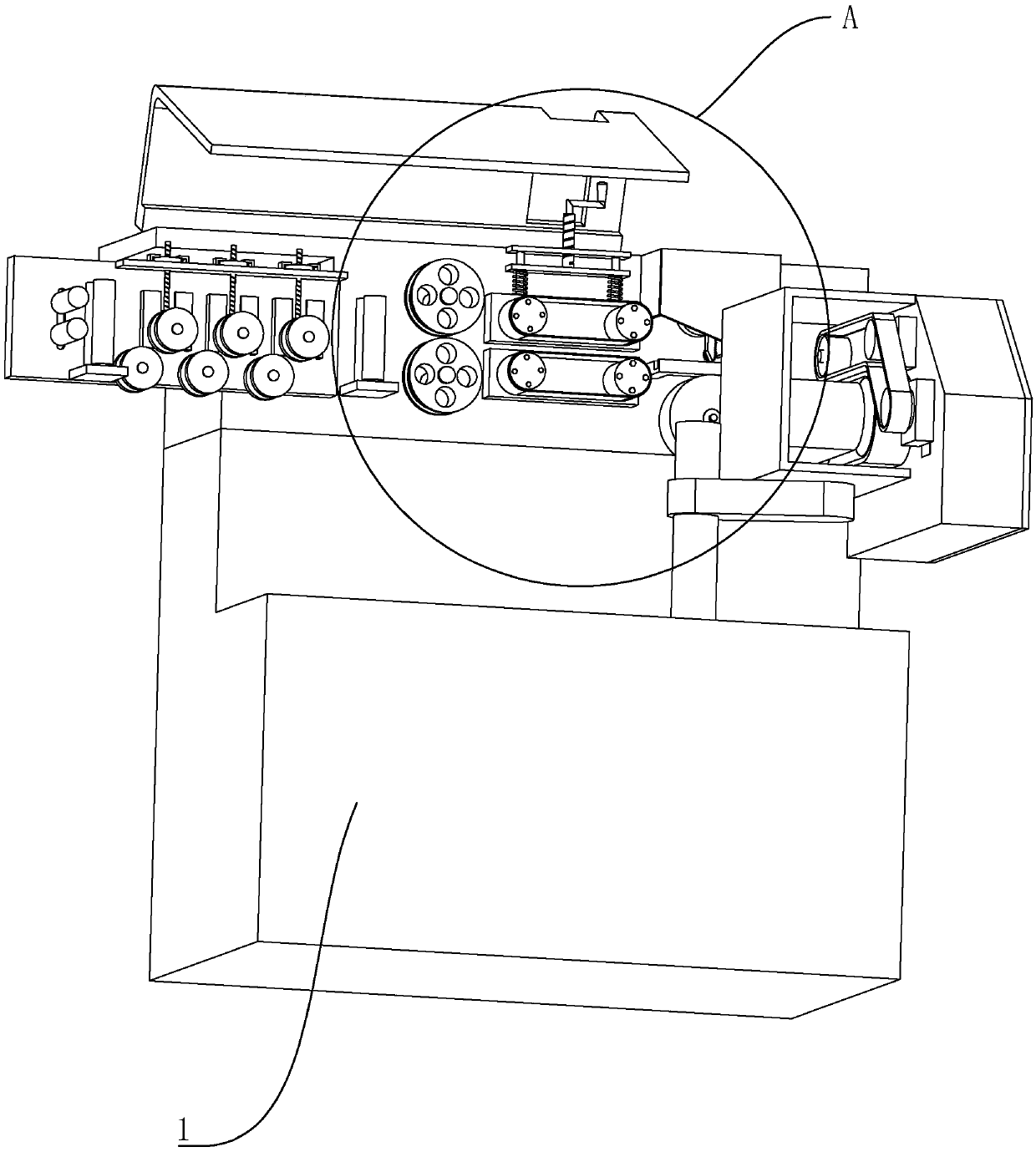

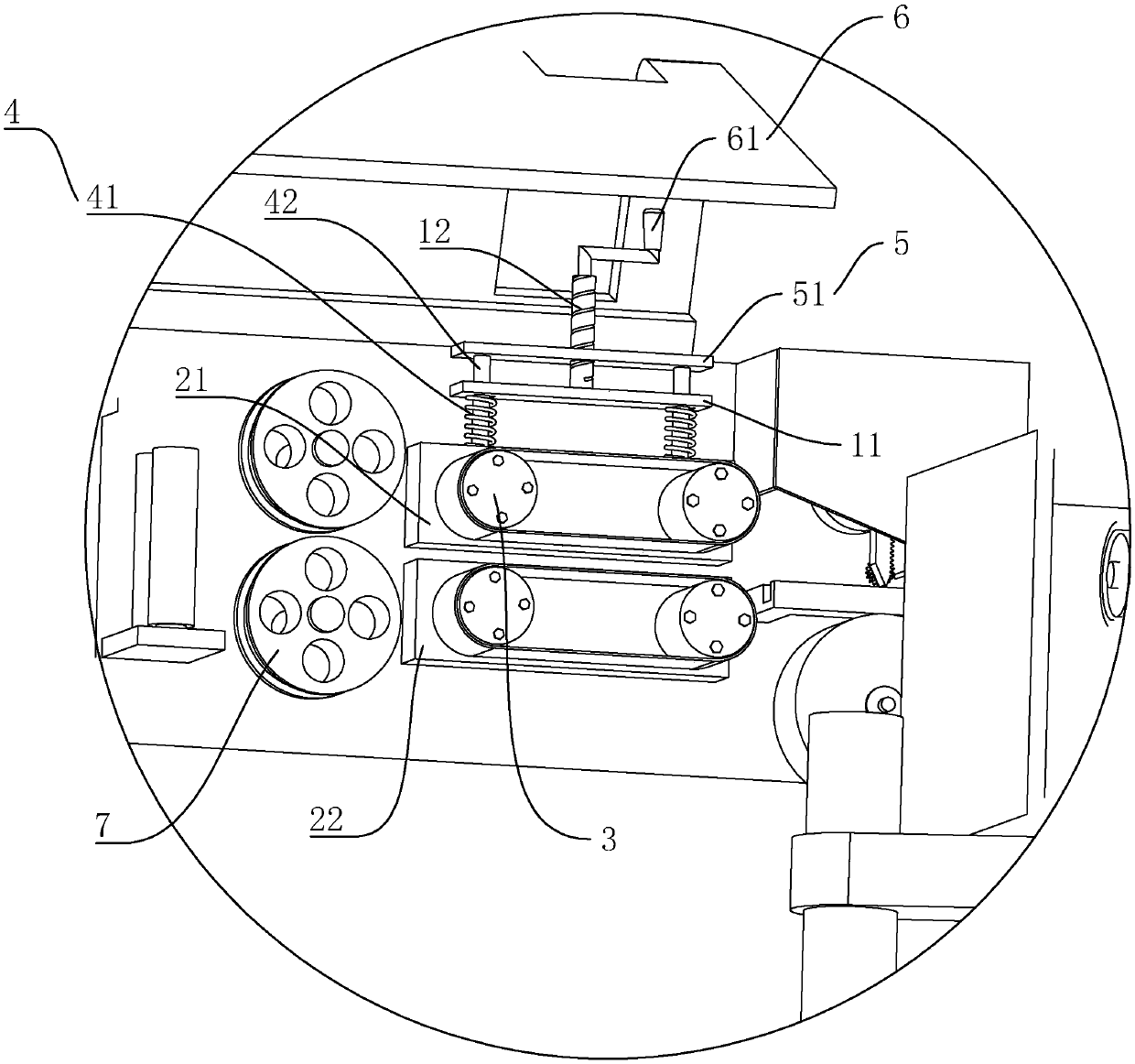

[0032] Embodiment 1, a cable transmission device, such as figure 1 and figure 2 As shown, it includes a strip-shaped frame 1, and two leveling wheels 7 arranged symmetrically up and down on the left side of the frame 1 are fixed on the left side of the frame 1 for flattening the cables entering therein. The diameter of the leveling wheel 7 is relatively large, so that the cables can be leveled to facilitate its use.

[0033] Such as figure 1 and figure 2 As shown, the frame 1 is provided with a transmission mechanism 2, and the transmission mechanism 2 includes an upper transmission seat 21 that is slidably connected on the frame 1 and a lower transmission seat 22 that is fixed on the frame 1 corresponding to the upper transmission seat 21, and the upper transmission seat 21 and the lower transmission seat 22 are correspondingly rotatably connected with a transmission wheel 3 for conveying cables, and the cables pass between the upper transmission seat 21 and the lower tr...

Embodiment 2

[0038] Embodiment 2 A cable transmission device. The difference from Embodiment 1 is that the adjustment member 6 includes an adjustment bolt sleeved on the adjustment screw. The adjustment bolt is threadedly connected to the adjustment screw. plate 51. A limit ring is provided on the adjusting bolt, and a limit groove adapted to the limit ring is opened on the positioning plate 51, and the limit ring is embedded in the limit groove.

Embodiment 3

[0039] Embodiment 3, a servo wire cutting machine, including Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com