Parallel shaft shared guide rail device

A technology of sharing guide rails and parallel guide rails, which is applied in the directions of transmission devices, shafts, bearings, etc., and can solve the problem that multiple guide rails cannot be installed, and achieve the effect of cost saving and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

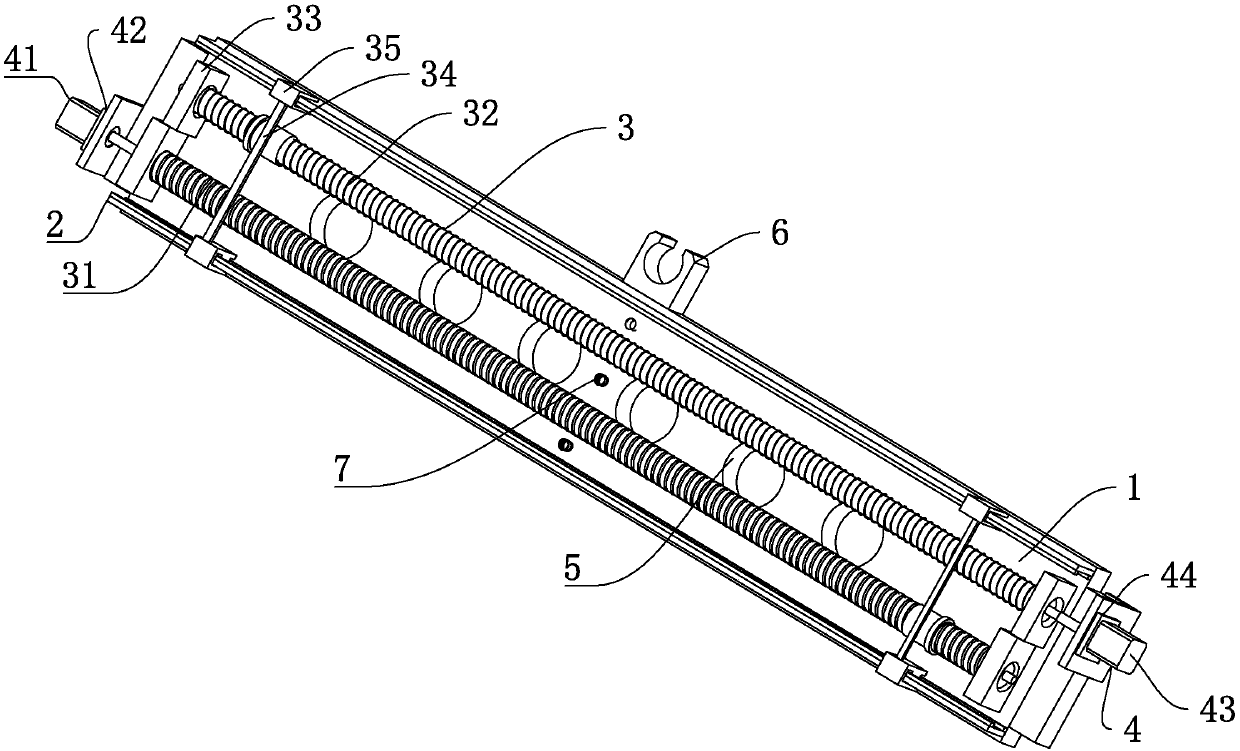

[0021] Embodiment 1: A kind of parallel axis shared rail device, such as figure 1 As shown, including the base part 1, a number of through holes 5 are also provided on the base part 1, and a number of bolt holes 7 are also provided on the surface of the base part 1. Two parallel guide rails 2 are arranged on both sides of the base part 1, and the base part 1 is located on the guide rail. 2, a connection block 6 is also provided on one side, and a common device 3 is also provided on the base part 1. The common device 3 includes a first screw rod 31 and a second screw rod 32 located between two parallel guide rails 2, and the base part 1 The two ends are respectively provided with bearing blocks 33 that are rotatably connected to the tops of the first screw mandrel 31 and the second screw mandrel 32, and the first screw mandrel 31 and the second screw mandrel 32 are also sleeved with a station 34, and the station 34 Sliders 35 for snapping into the guide rails 2 on both sides ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com