A sand dehydration collection device for engineering construction

A collection device and technology for construction, which is applied in the field of sand and stone dehydration collection devices for engineering construction, can solve the problems of mixing, large manpower consumption, poor quality, etc., and achieve the effect of convenient operation, less manpower consumption, and consistent particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

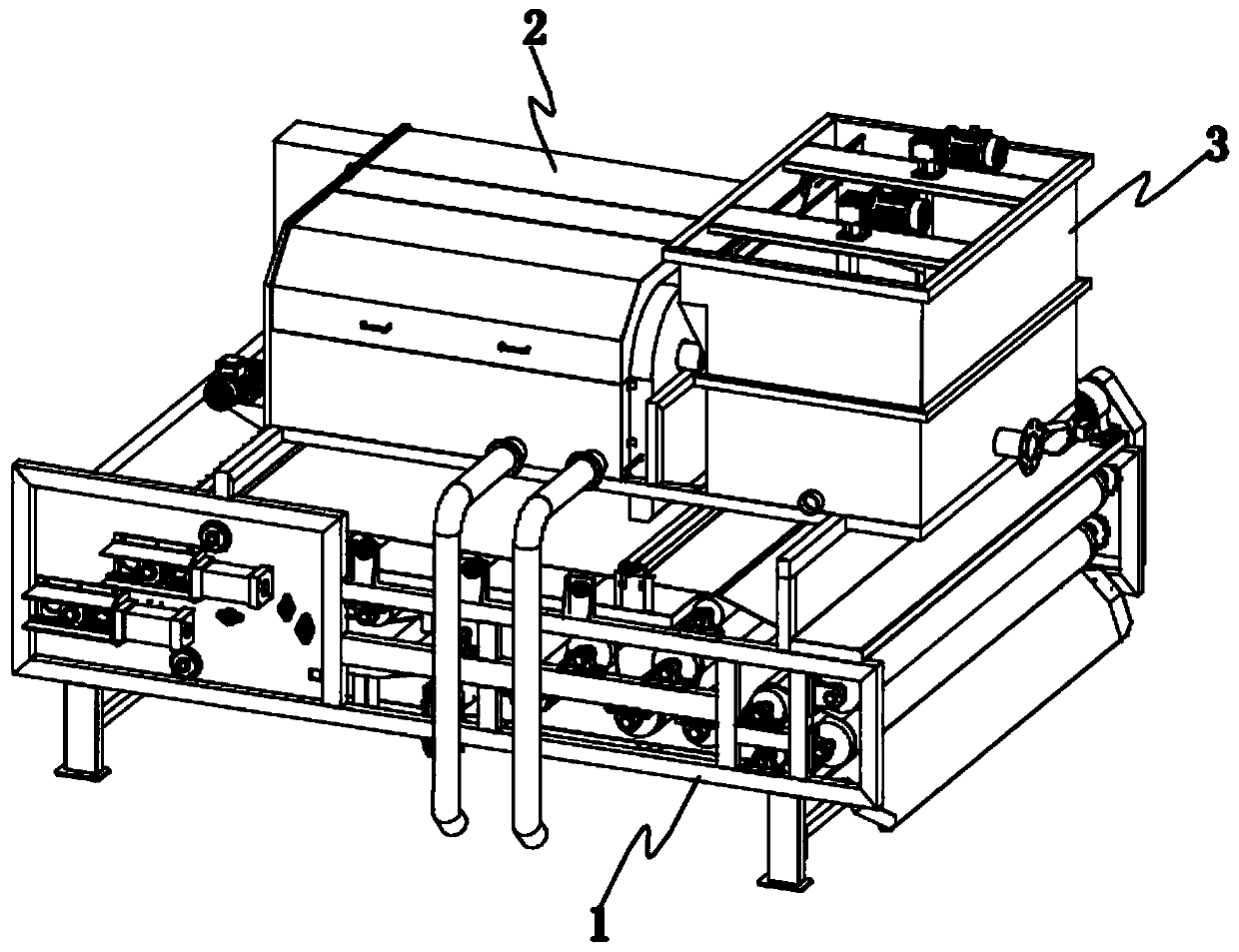

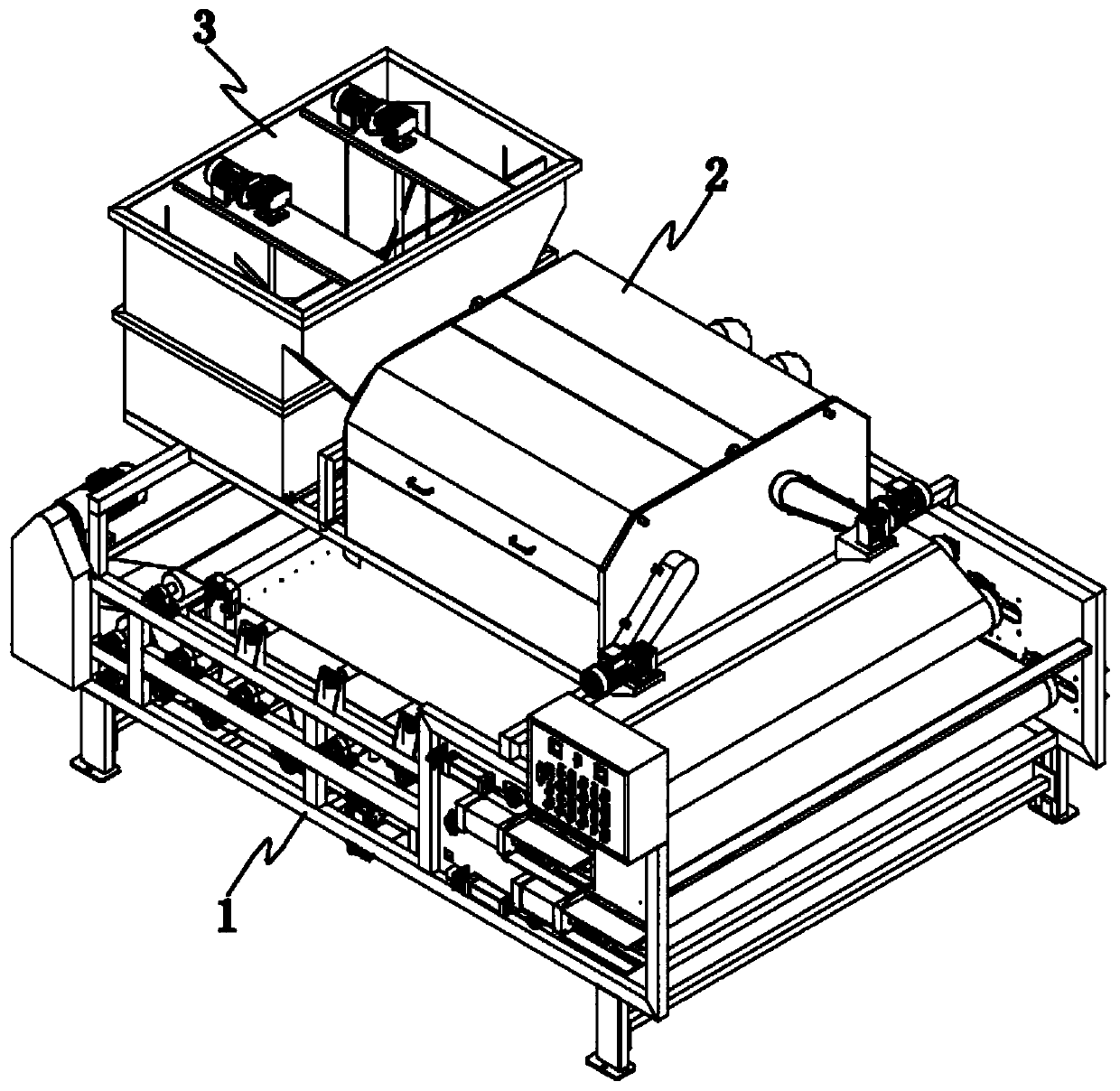

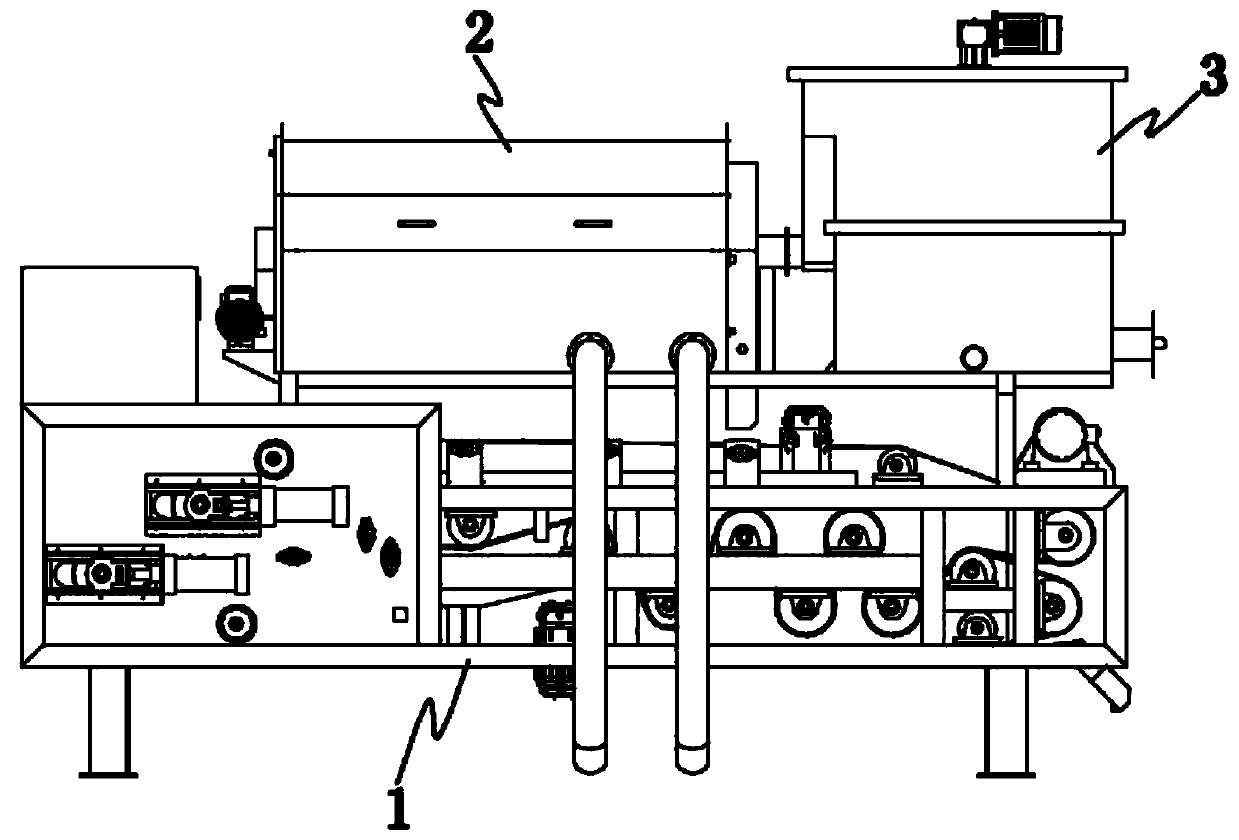

Embodiment 1

[0035] The stirring input mechanism 3 of this device first inputs the river water mixed with sand and mud debris through the input nozzle 305. After the river water enters the stirring box 301, the stirring motor 303 is started, and the stirring shaft 304 pairs in the stirring box 301 are driven by the stirring motor 303. The river water is stirred, and catalyst is added to the auxiliary input pipe 306 on the side pipe wall of the input nozzle 305 at the same time, which can accelerate the accumulation and sedimentation of large particles in the river water in the stirring box 301. After fully stirring, manually turn the screw nut 310 to adjust the flow rate The adjustment plate 311 moves along the transverse slot 309, thereby opening the output nozzle 308, and adjusting the size of the output nozzle 308, so that the river water flows into the filter collection mechanism 2 along the mixing input pipe 202 connected to the output nozzle 308 to remove fine sand. Filtrate, and simu...

Embodiment 2

[0037] The mixing material input pipe 202 in the filter collection mechanism 2 is connected in the filter framework cylinder 206, and the river water is input into the filter framework cylinder 206 along the material mixing input pipe 202, wherein the filter screen 216 on the surface of the filter framework cylinder 206 filters out the Fine sand, wherein the filter skeleton cylinder 206 is driven and rotated by the filter driving motor 209 on the rear end surface of the chassis body 201, so as to realize the comprehensive filtration of the river water by the filtration skeleton cylinder 206, and the filtering effect is good. Discharge, and discharge to the filter cloth 103 on the dehydration output base 1 along the drain port 210 between the drain cover 203 and the outer surface of the front end of the cabinet body 201, wherein an adjustment plate 211 is set in the drain port 210, which can be manually adjusted The operating rod 212 rotates the adjustment plate 211 to adjust th...

Embodiment 3

[0039] The rotating roller 102 in the dehydration output base 1 of the device is driven to rotate by the conveying motor 105 at the side end, thereby driving the filter cloth 103 wound on the rotating roller 102 to move, and the river water flowing out from the drain 210 falls on the filter cloth 103 , the filter cloth 103 can filter out the silt in the river water, wherein the rotating roller 102 is arranged in parallel with two rows up and down in the dehydration output base 1, to realize the upper and lower layers of river water filtration, the silt filter is fully and thoroughly, and the filtered river water rotates from the lower layer The filter cloth 103 on the roller 102 drips and flows out, and the sludge on the filter cloth 103 moves forward with the rotation of the rotating roller 102, and finally is discharged from the output guide plate 107 on the side end of the dehydration output base 1, wherein the bottom frame is fixed The tension adjustment cylinder 104 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com