A long-life steel suitable for fracturing pump valve body in unconventional oil and gas operations and its forging method

An unconventional, long-life technology, applied in the field of alloy steel, can solve the problems of short service life, difficult forming, fatigue damage, etc., achieve consistent internal and external grain size, overcome excessive heating time, and refine grains. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

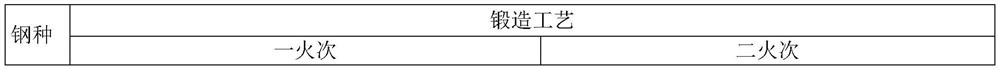

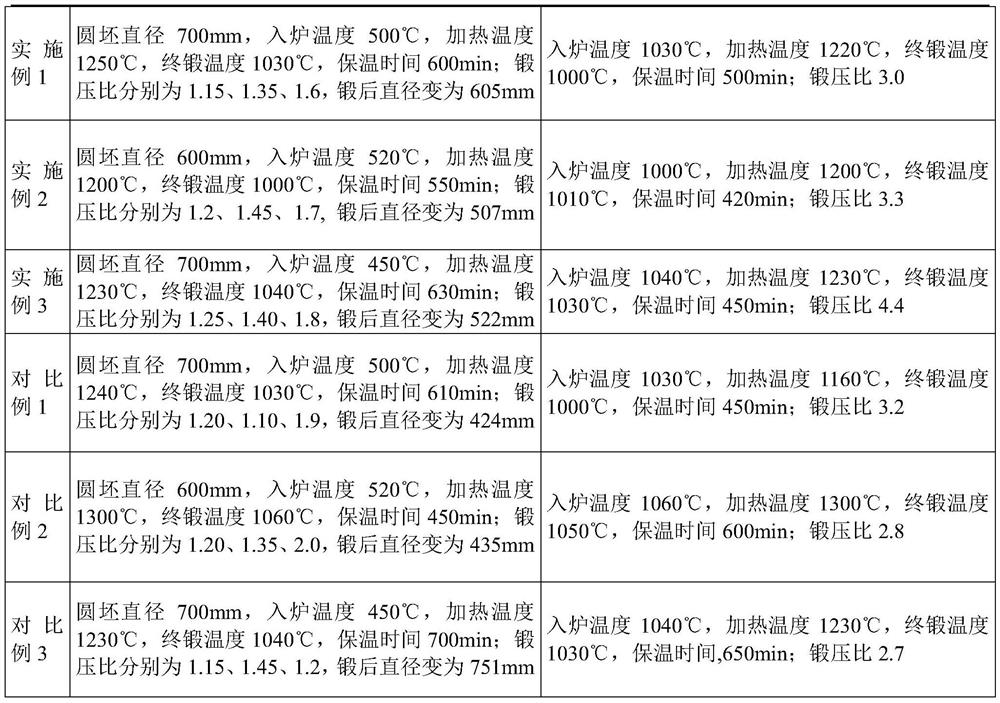

Embodiment 1-3

[0053] Long service life is suitable for steel used for fracturing pump valve body in unconventional oil and gas operations. The weight percentage of each element composition is shown in Table 1, and the balance not listed in Table 1 is Fe and unavoidable impurities. Wherein the A value in each embodiment is calculated by A=%C-(0.077×%Cr+0.24×%V), and embodiment 1-3 satisfies 0.20%≤A≤0.32%; X value is passed through X=4×%Ni +1.2×%Cr-1.5×%Si+17×%Sb+10×%V-9×%Ni×%Sb-5×%Mn, Examples 1-3 satisfy X≥1.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com