Concrete continuous girder cantilever construction load balance adjusting device and method

A construction load and balance adjustment technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as continuous beams cannot be guaranteed, concrete pouring progress cannot be kept completely synchronized, major safety accidents, etc., to ensure balance and stability performance, security assurance, and the effect of increasing tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

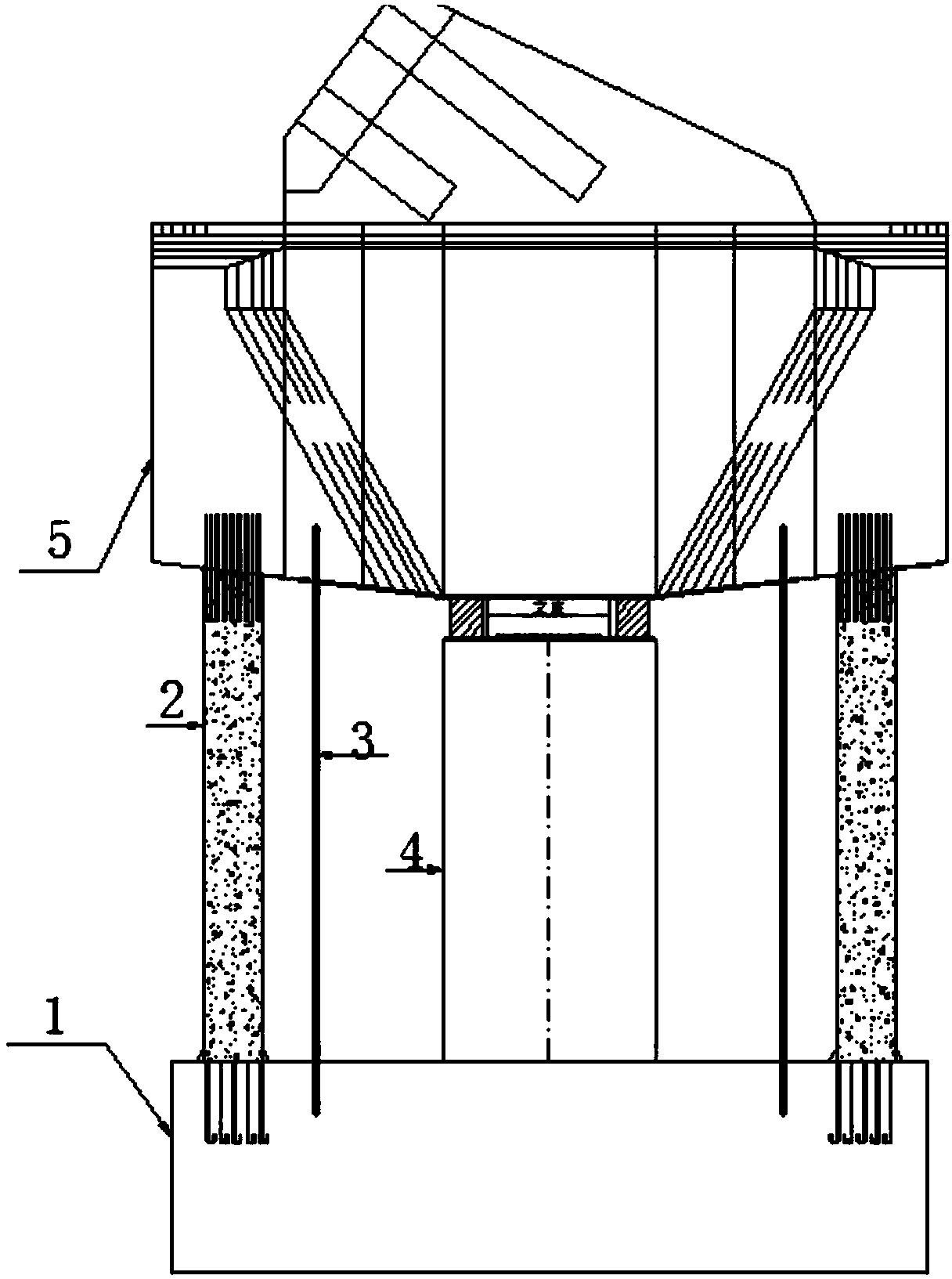

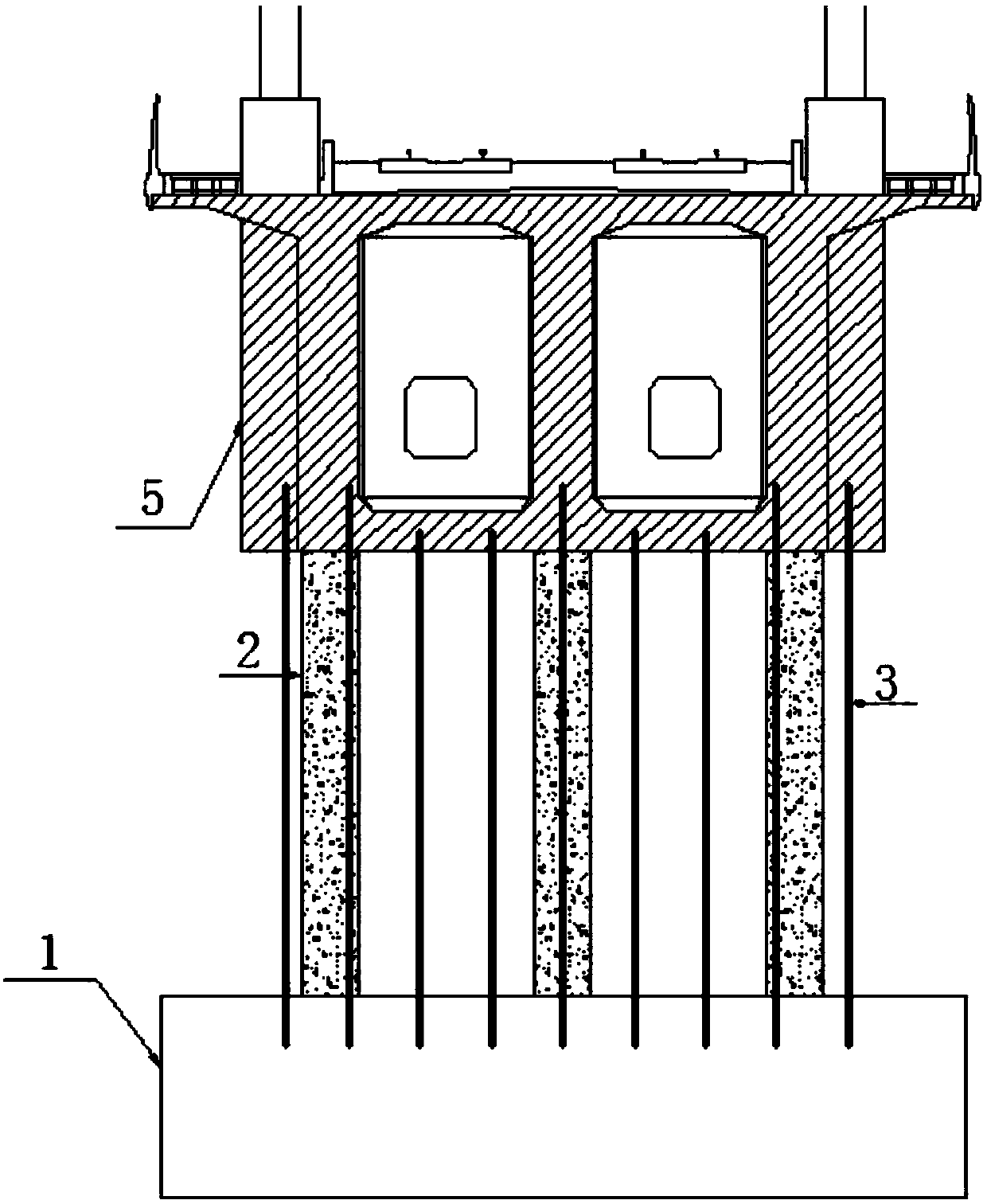

[0023] A load balance adjustment device for concrete continuous beam cantilever construction. Temporary support piers 2 are arranged on the main beam cap 1 on both sides of the main girder pier body 4, and the upper end of the main girder pier body 4 carries the beam body 5. 1 and the beam body 5 are located on both sides of the main beam cap 1 and are buried with finish-rolled rebar 3 .

[0024] The finish-rolled rebars 3 can be connected by extensions.

[0025] 9-12 pieces of finish-rolled rebar 3 are respectively installed on both sides of the main beam cap 1 .

[0026] The finish-rolled rebar 3 is selected from Φ32 finish-rolled rebar.

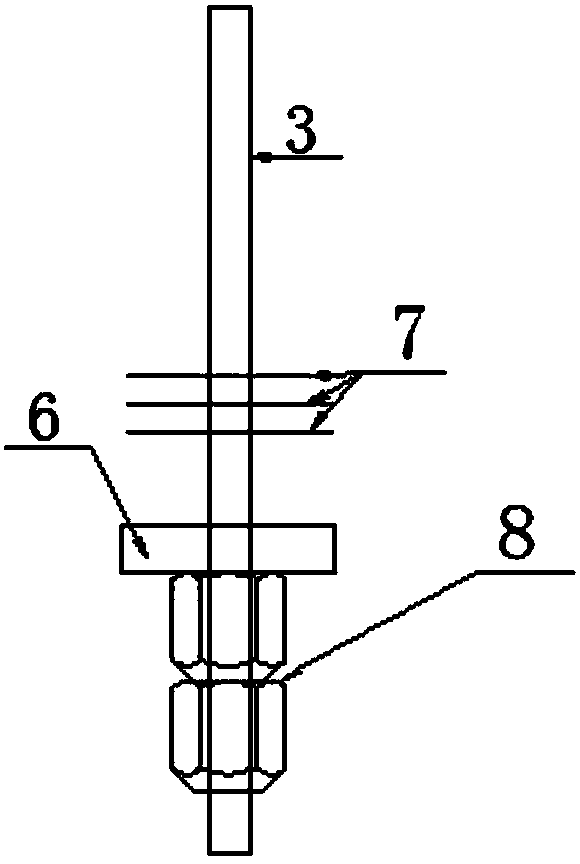

[0027] The upper and lower ends of the finish-rolled rebar 3 are provided with anchor backing plates 6, the upper end of the embedded beam body is provided with double nuts 8 above the anchor backing plate 6, and three steel mesh sheets 7 are arranged under the anchor backing plate 6; Double nuts 8 are arranged below the anchor backing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com