Vehicle silencer with multi-stage silencing assembly

A muffler and vehicle technology, applied in the direction of mufflers, engine components, machines/engines, etc., can solve the problems of not being able to judge whether the engine noise is normal, the structure of the vehicle muffler is complicated, and the service life of the muffler is affected, and the structure is simple and fast. , the effect of preventing dangerous situations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

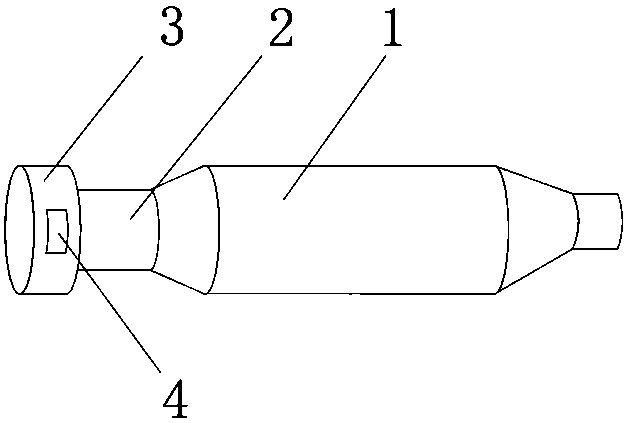

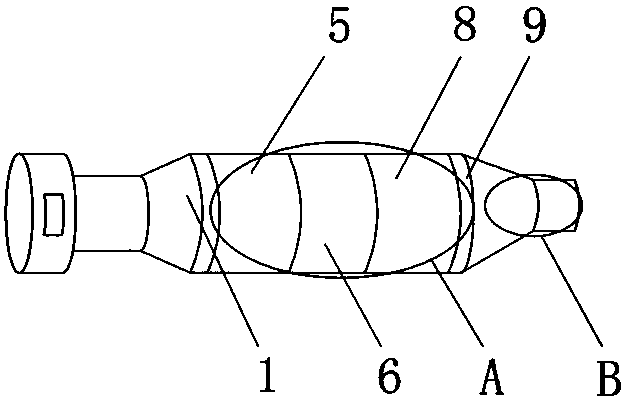

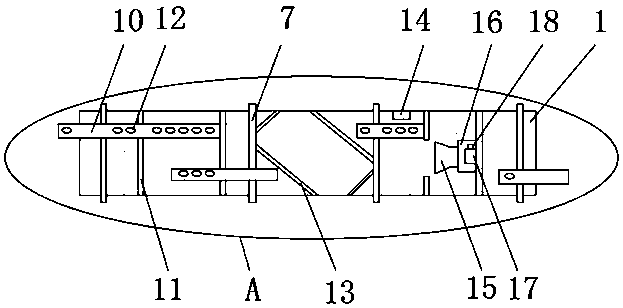

[0018] Such as Figure 1-4 As shown, a vehicle muffler with a multi-stage muffler assembly includes a muffler main body 1, a sound inlet pipe 2 and an oil resistance tank 3 are arranged on one side of the outer surface of the muffler main body 1, and one side of the outer surface of the oil resistance tank 3 Fixedly connected to the outer surface of the other side of the sound inlet pipe 2, it can collect a small amount of gasoline leaked when the engine is working, prevent gasoline from entering the muffler, protect the muffler, prevent dangerous situations, prolong the service life of the muffler, and block the fuel tank 3 The outer surface of the front end is fixedly connected with a decibel meter 4. It is more practical to judge whether there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com