An automatic detection apparatus for elevator guide rails

An automatic detection, elevator guide rail technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of high production cost and sales price, complex structure, complex structure of the detection machine, etc., and achieve the effect of low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

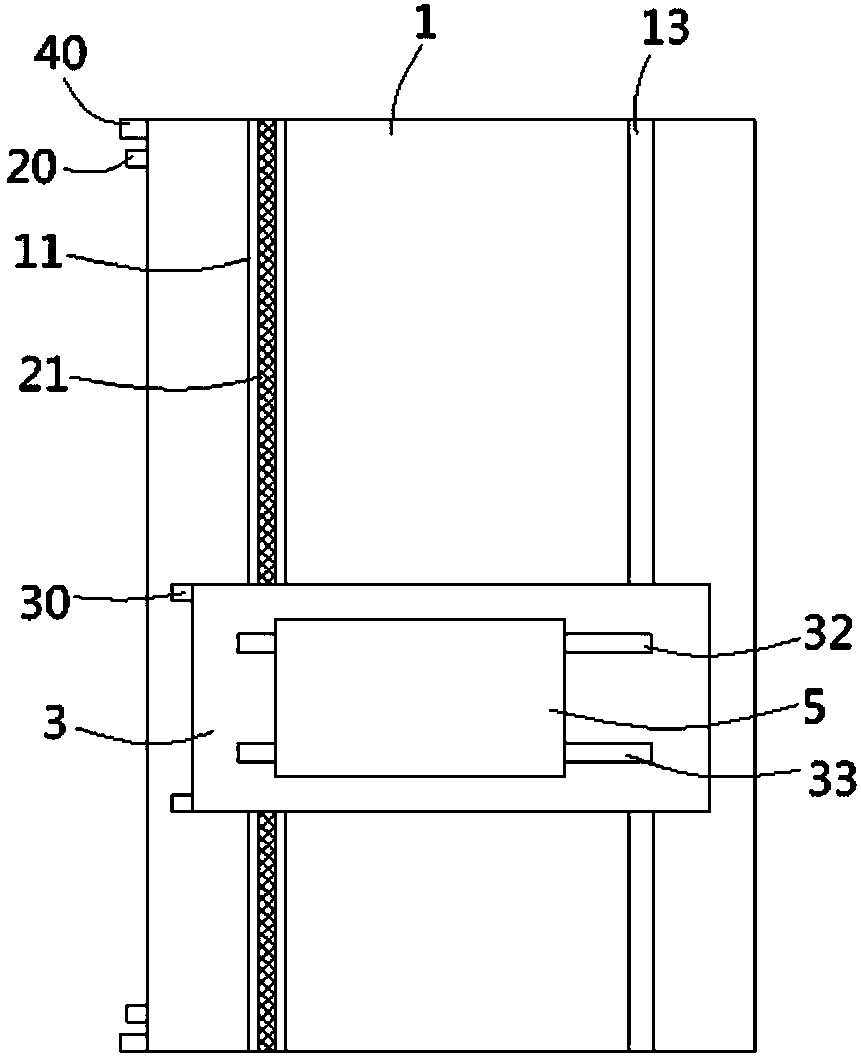

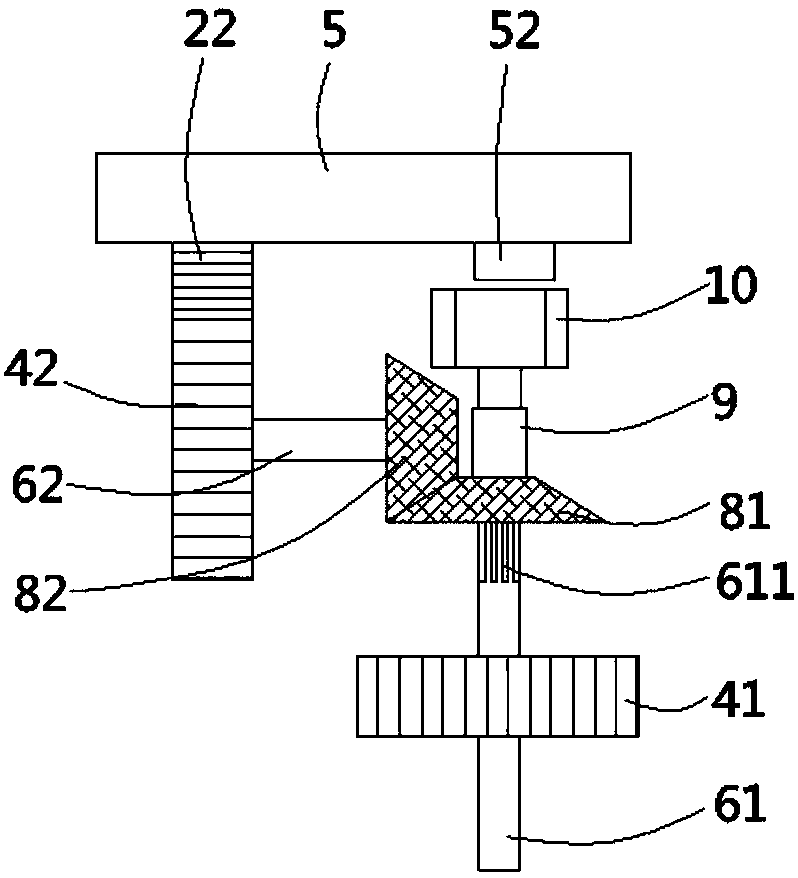

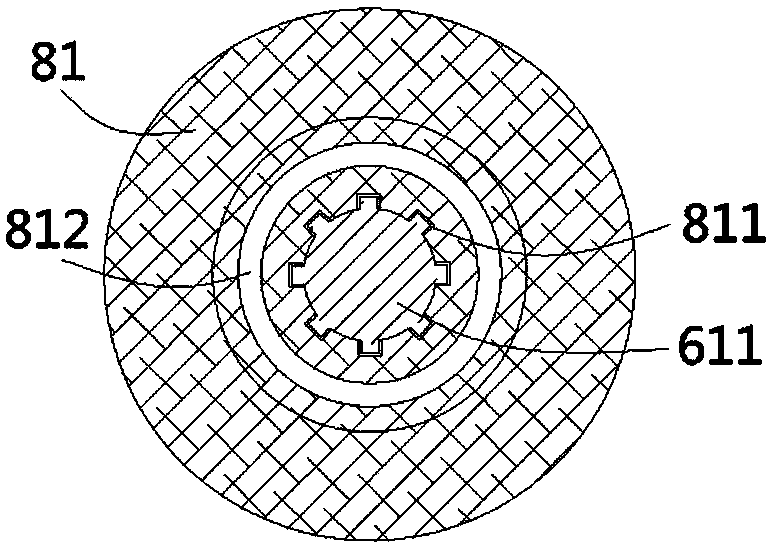

[0022] see figure 1 , figure 2 , Figure 5 , an automatic detection device for elevator guide rails according to the present invention, including a base 1, a first chute 11 is formed on the base 1, a first rack 21 is formed in the first chute 11, The base 1 is provided with a base plate 3 capable of sliding along the first chute 11, the base plate 3 is provided with a first gear 41, the lower end of the first gear 41 passes through the base plate 3 and is inserted into the first chute 11 Inside, the first gear 41 meshes with the first rack 21, the bottom plate 3 is provided with a second chute 32 perpendicular to the first chute 11, and the second chute 32 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com