An all-in-one machine suitable for mudstone dry-wet cycle test and triaxial test

A dry-wet cycle, triaxial test technology, used in the application of stable tension/pressure to test the strength of materials, use of wave/particle radiation for material analysis, instruments, etc., to achieve the effect of accelerating drying rate and exquisite design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, and the content of the present invention is not limited to the following embodiments.

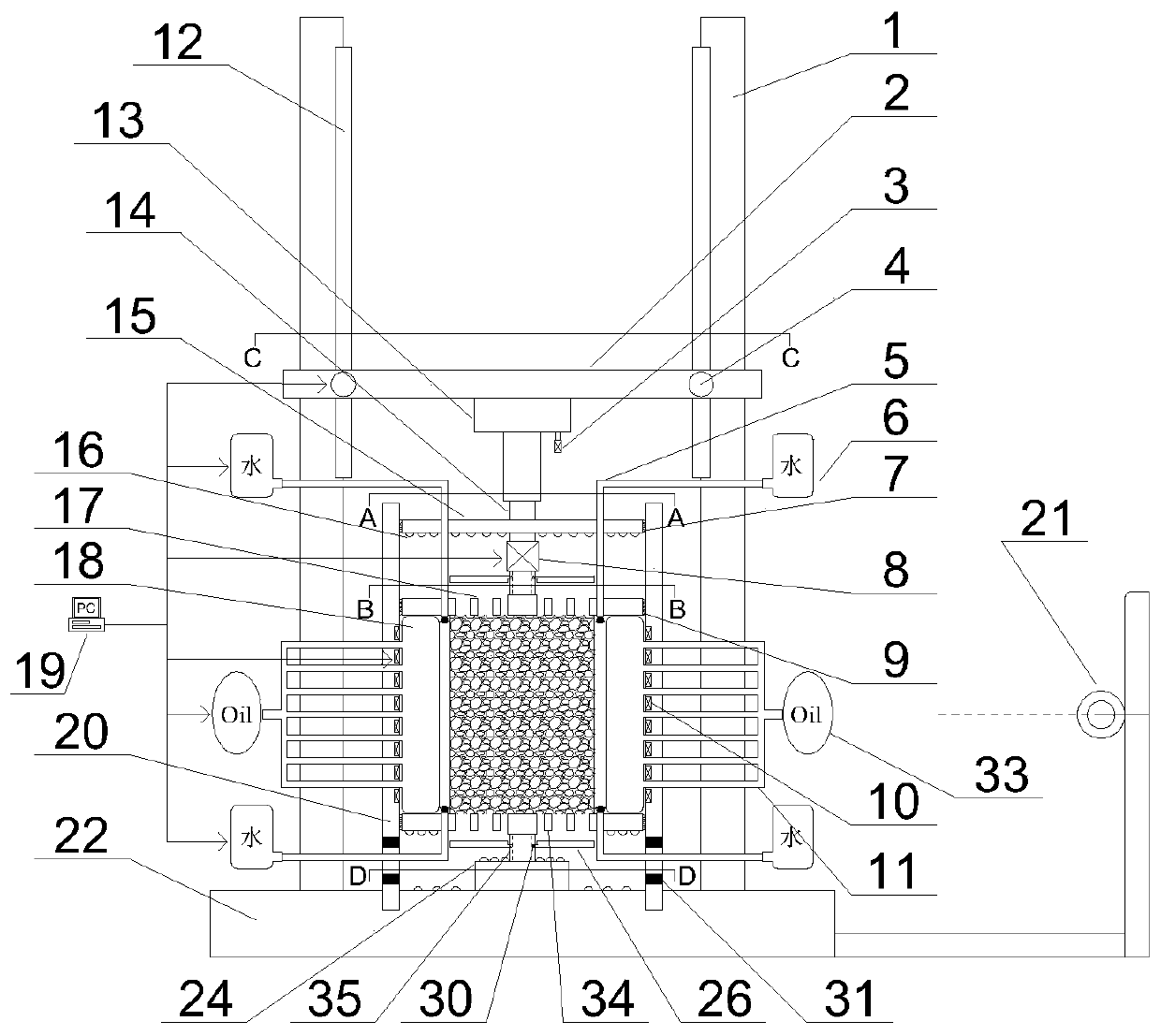

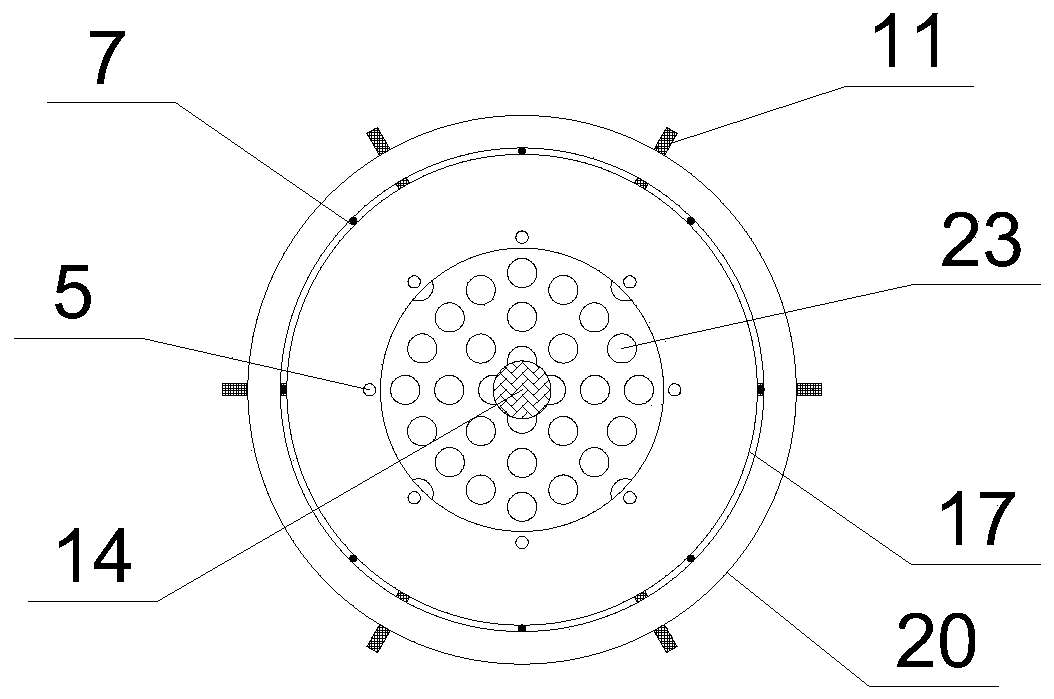

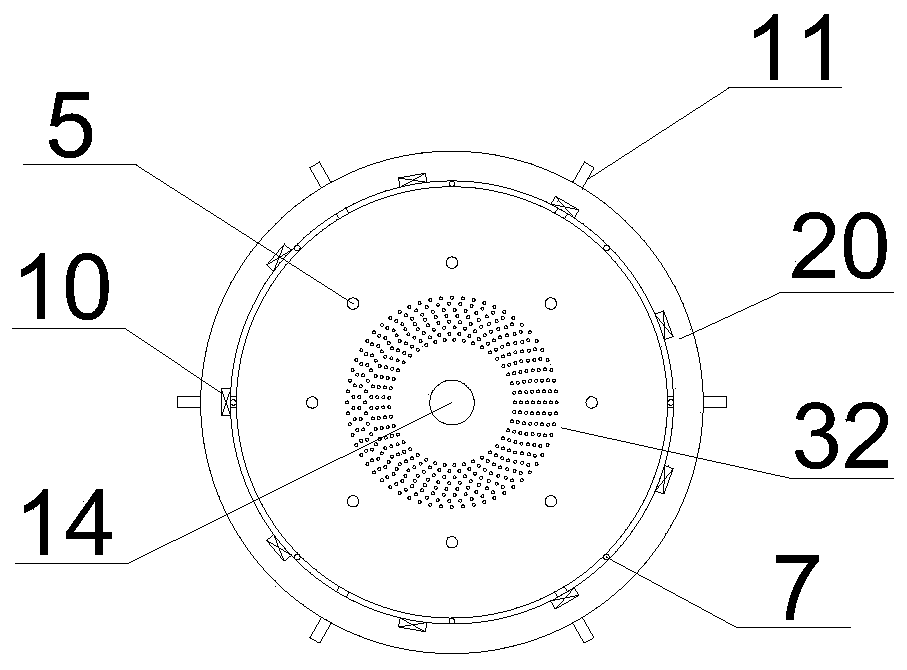

[0043] The ring shear test and soil sample preparation device suitable for vertical shear planes provided by the present invention have a structure such as figure 1 As shown, it includes five parts: test cylinder, hydraulic lifting system, oil pressure loading system, computer monitoring and control system and frame. The basic framework of the present invention is mainly composed of a test tube, a base 22 and a column 1 mounted thereon. In the upper part, the hydraulic lifter 12 is installed on the column 1 at both ends, and the hydraulic lifter 2 is mounted on the hydraulic lifter 12. The bottom surface of the lifter 2 is welded with a connecting shaft carrier platform 13 in the center, and the top axial pressure plate 14 is connected with the carrier platform 13, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com