Sample gas intake system for on-line gas chromatographic detection

A technology of air intake system and gas chromatography, which is applied in the field of gas analysis, can solve the problems of sample gas sampling lag and easy damage of sampling pumps, and achieve accurate detection results and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

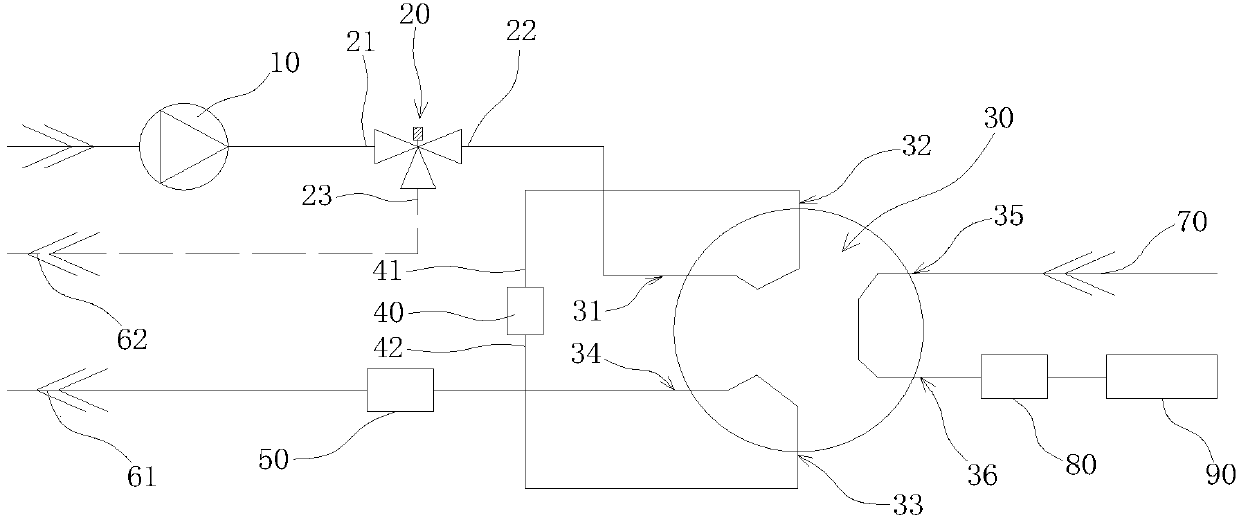

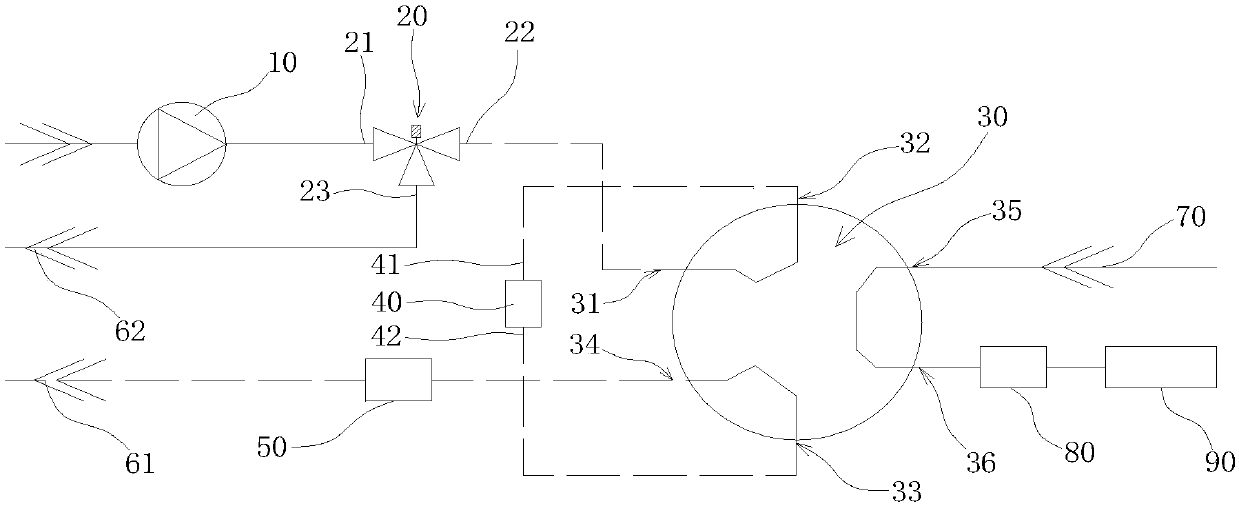

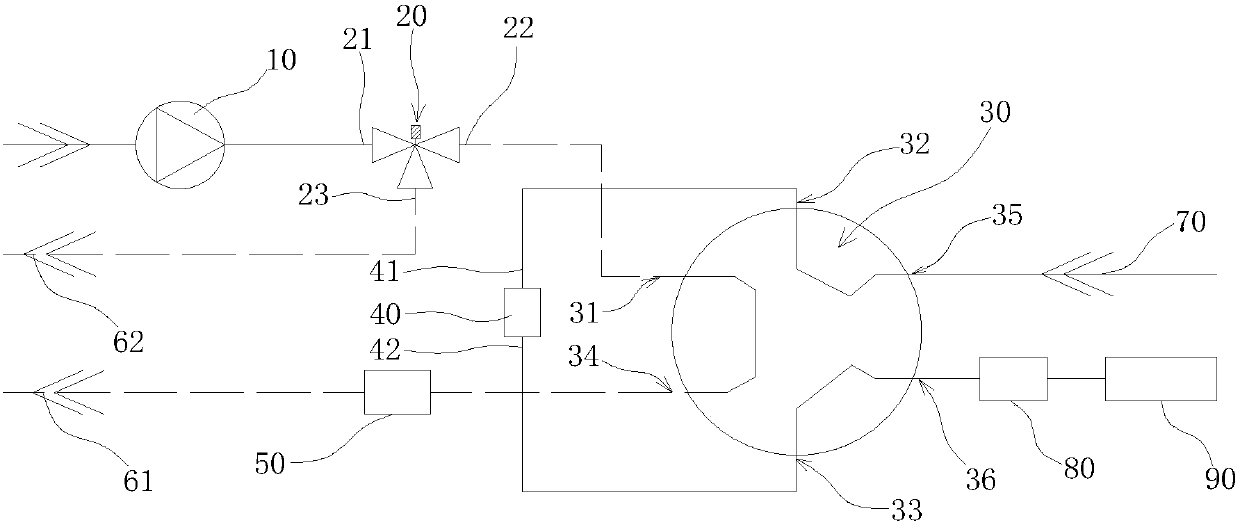

[0012] combine figure 1 , 2 3. A sample gas inlet system for online gas chromatography detection. The inlet end of the sampling pump 10 is connected to the gas source, and the outlet end of the sampling pump 10 is connected to the first inlet port 31 of the reversing valve assembly 30; The gas inlet 41 of the sample gas quantitative storage unit 40 is connected to the first gas outlet 32 of the reversing valve assembly 30, and the gas outlet 42 of the sample gas quantitative storage unit 40 is connected to the second gas inlet 33 of the reversing valve assembly 30. The second air outlet 34 of the reversing valve assembly 30 is connected to the first exhaust port 61 through the buffer tank 50; the carrier gas pipeline 70 is connected to the third air inlet 35 of the reversing valve assembly 30, and the reversing valve assembly The third air outlet 36 of 30 is connected to the detection unit. The sample gas quantitative storage unit 40 can be understood as a section of pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com