Fault detection and response method by applying robot in numerical control lathe machining

A CNC lathe and fault detection technology, applied in computer control, general control systems, instruments, etc., can solve problems such as delays in production progress, enterprise losses, failure to locate faults, etc., and achieve the effect of avoiding early faults and reducing the probability of downtime for maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

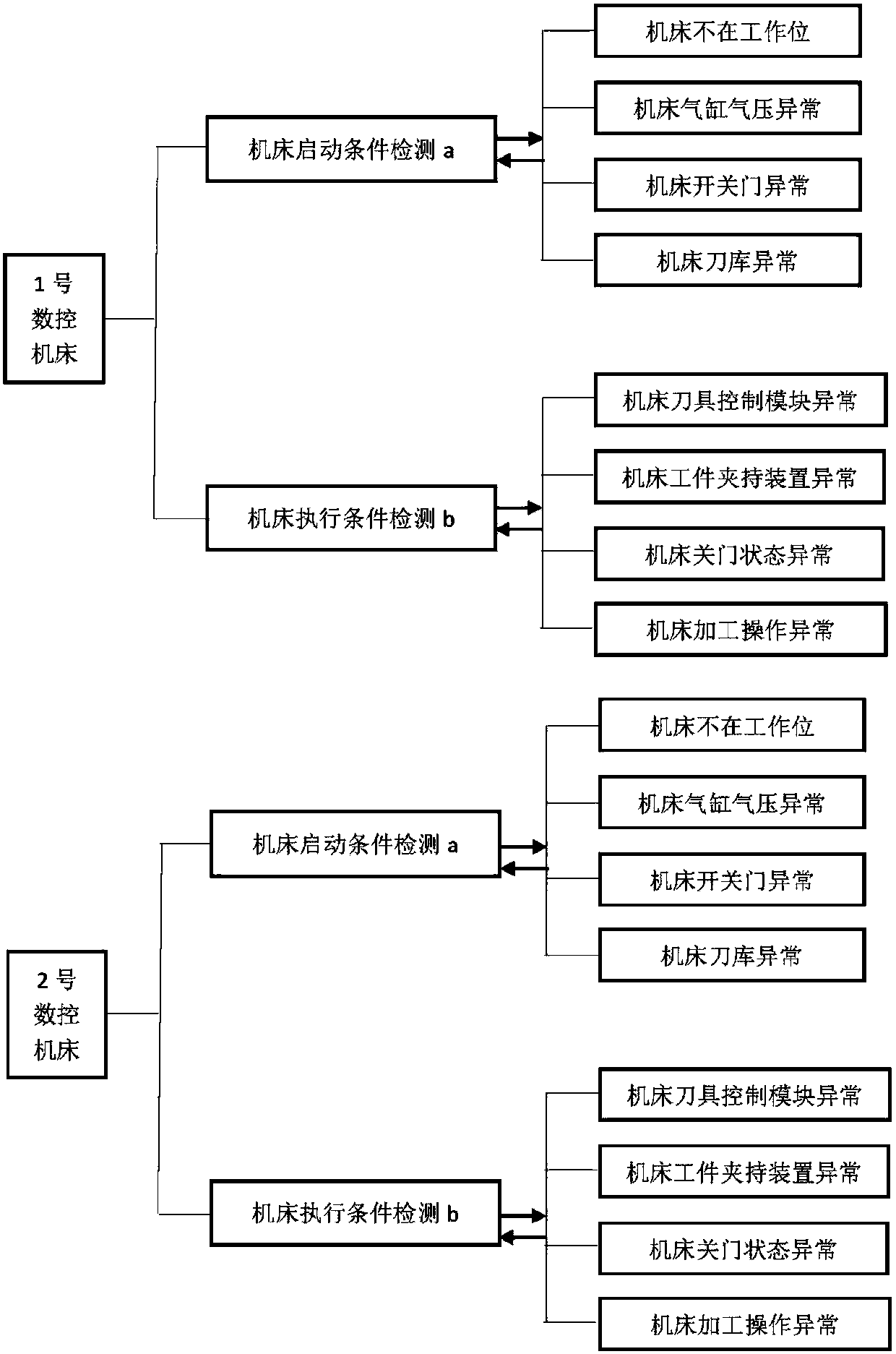

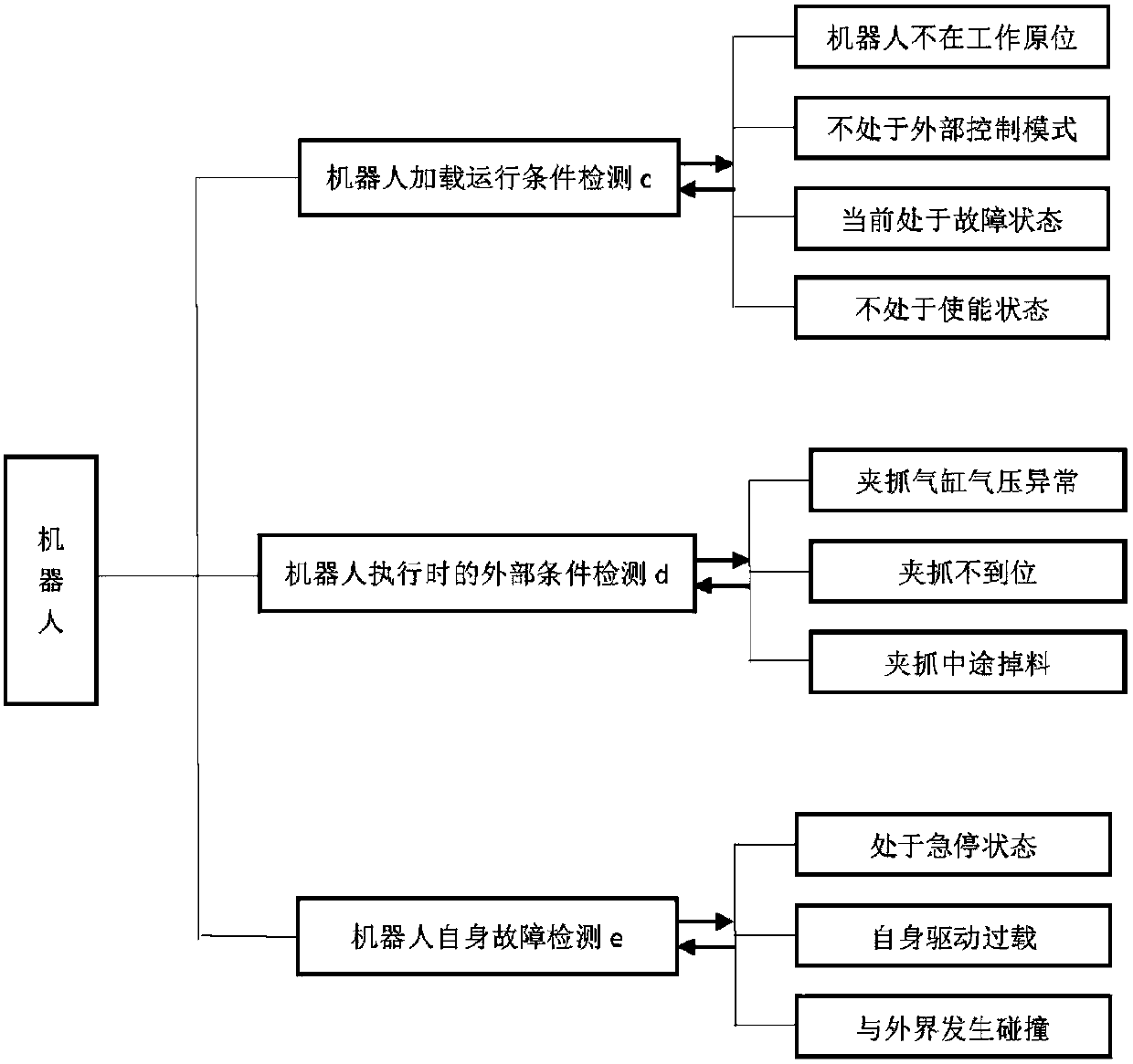

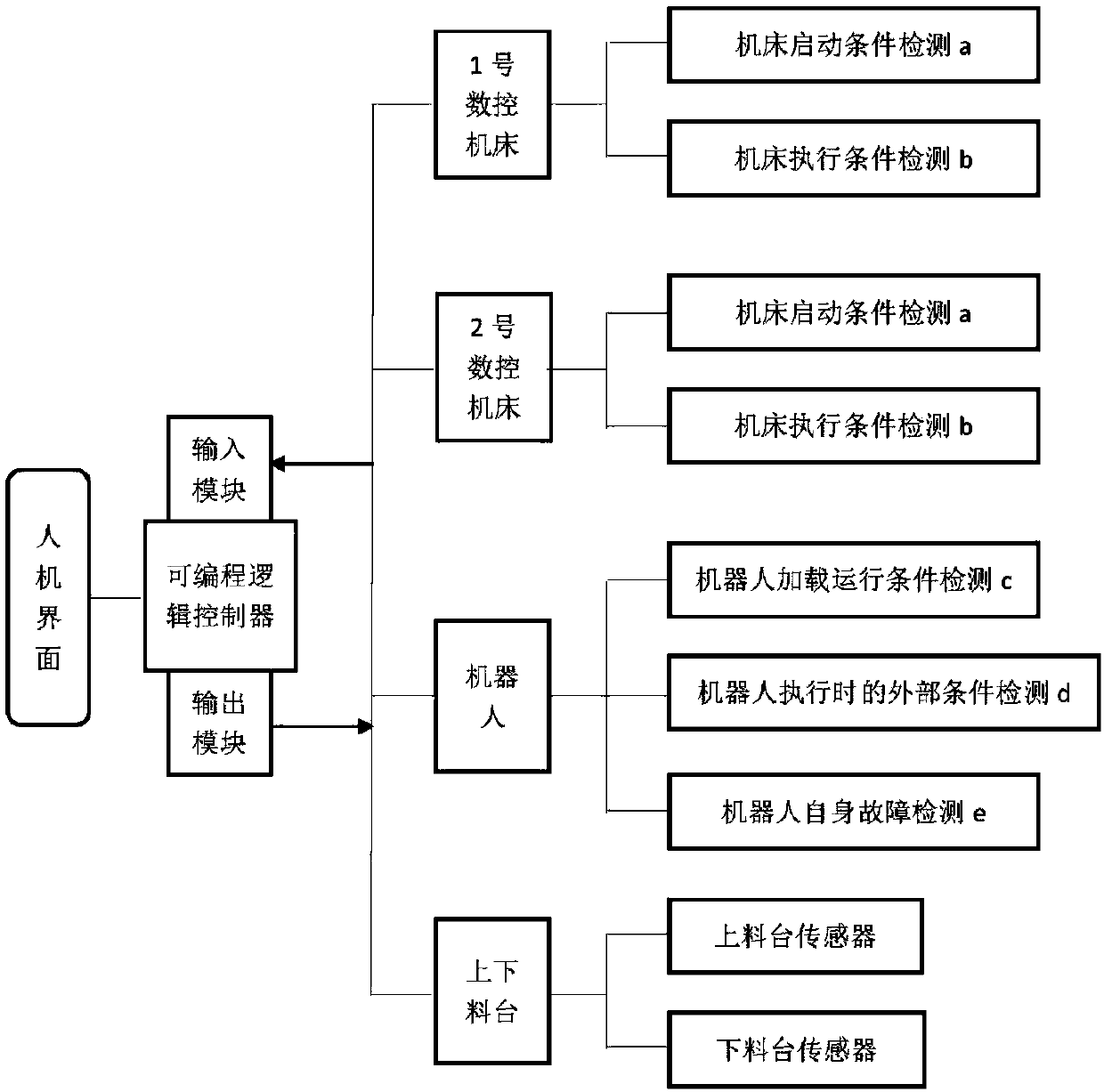

[0044] refer to figure 1 As shown, a fault detection and response method for a robot applied in CNC lathe processing, simultaneously controlling two CNC machine tools, a ground rail robot and a loading and unloading platform, its implementation should meet the following hardware conditions, including: a central processing unit , the programmable logic controller of the input module and the output module, the man-machine interface connected to the programmable logic controller with a network cable and the sensor set on the loading and unloading table; the corresponding controlled CNC machine tool, The number information and fault codes of the ground rail robot and the loading and unloading platform sensors. The man-machine interface is equipped with a display screen for displaying fault codes, a fault light and a calling module. The sensors correspond to the station settings of the loading and unloading table.

[0045] The central processing unit on the programmable logic contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com