Automatic bread slice roaster

A technology for slices of bread and toasters, applied in the field of automatic sliced bread toasters, can solve problems such as hidden safety hazards, influence on eating experience, electric shock safety accidents, etc., and achieve the effects of avoiding electric leakage, ensuring uniform baking, and improving eating experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

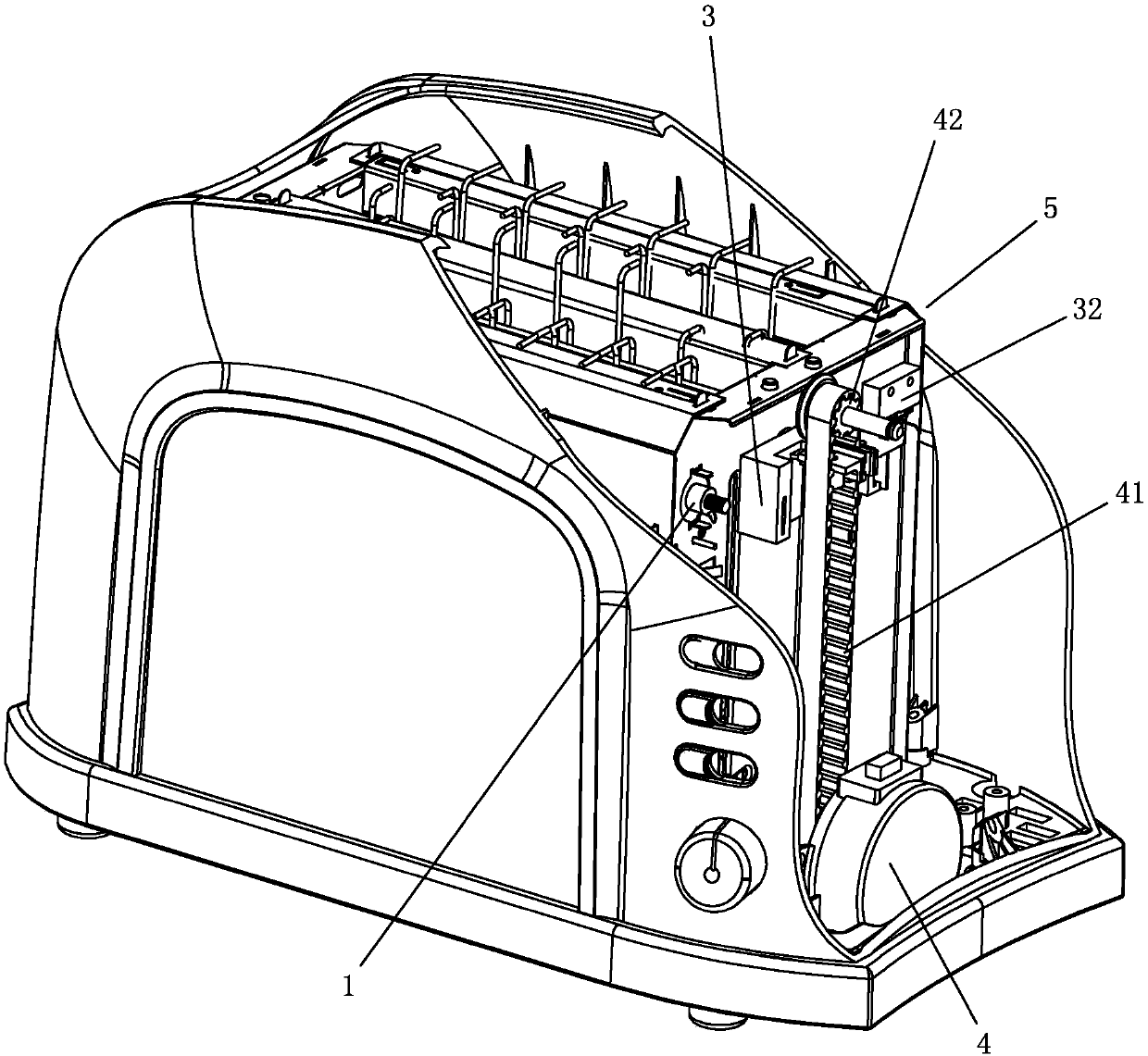

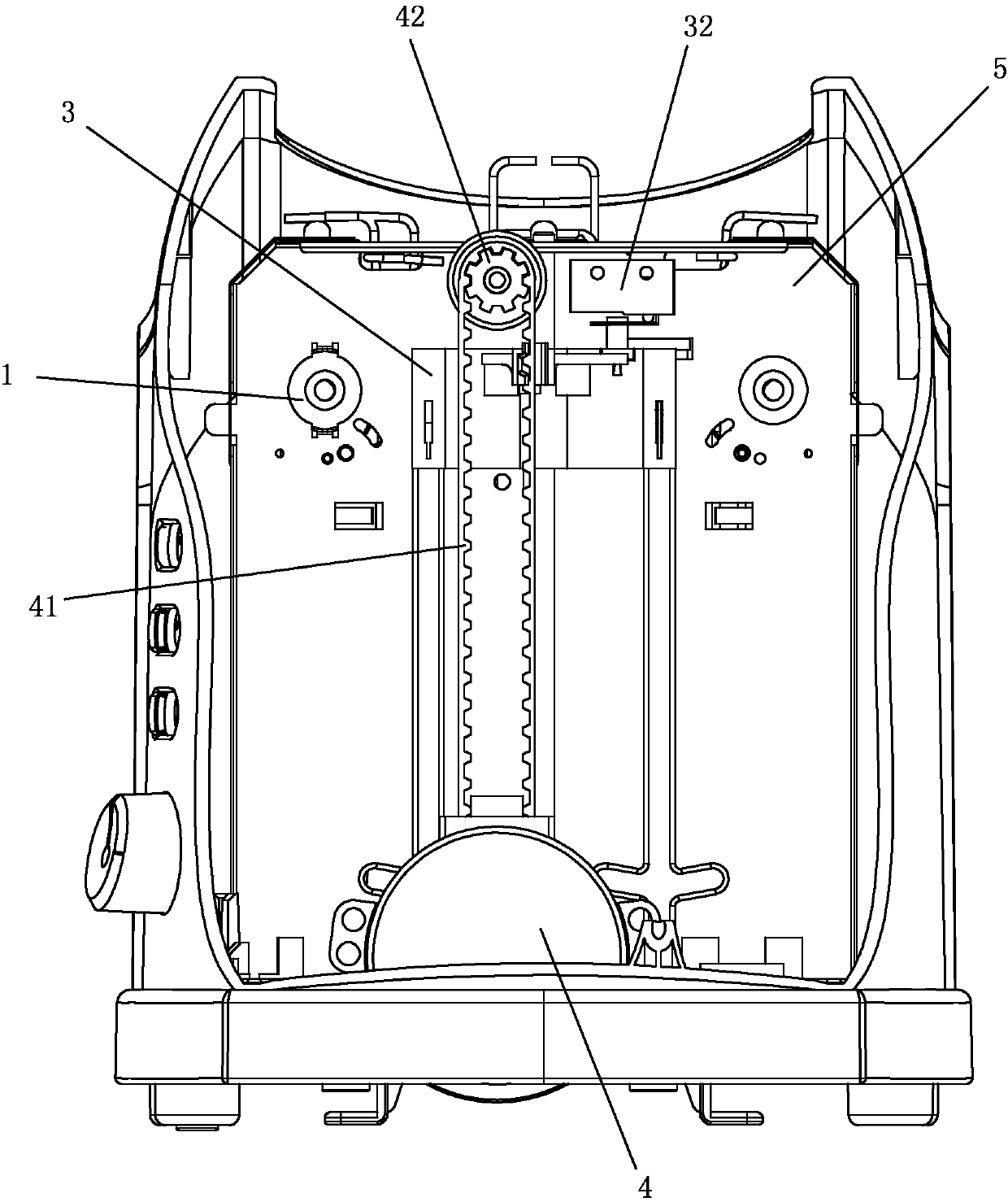

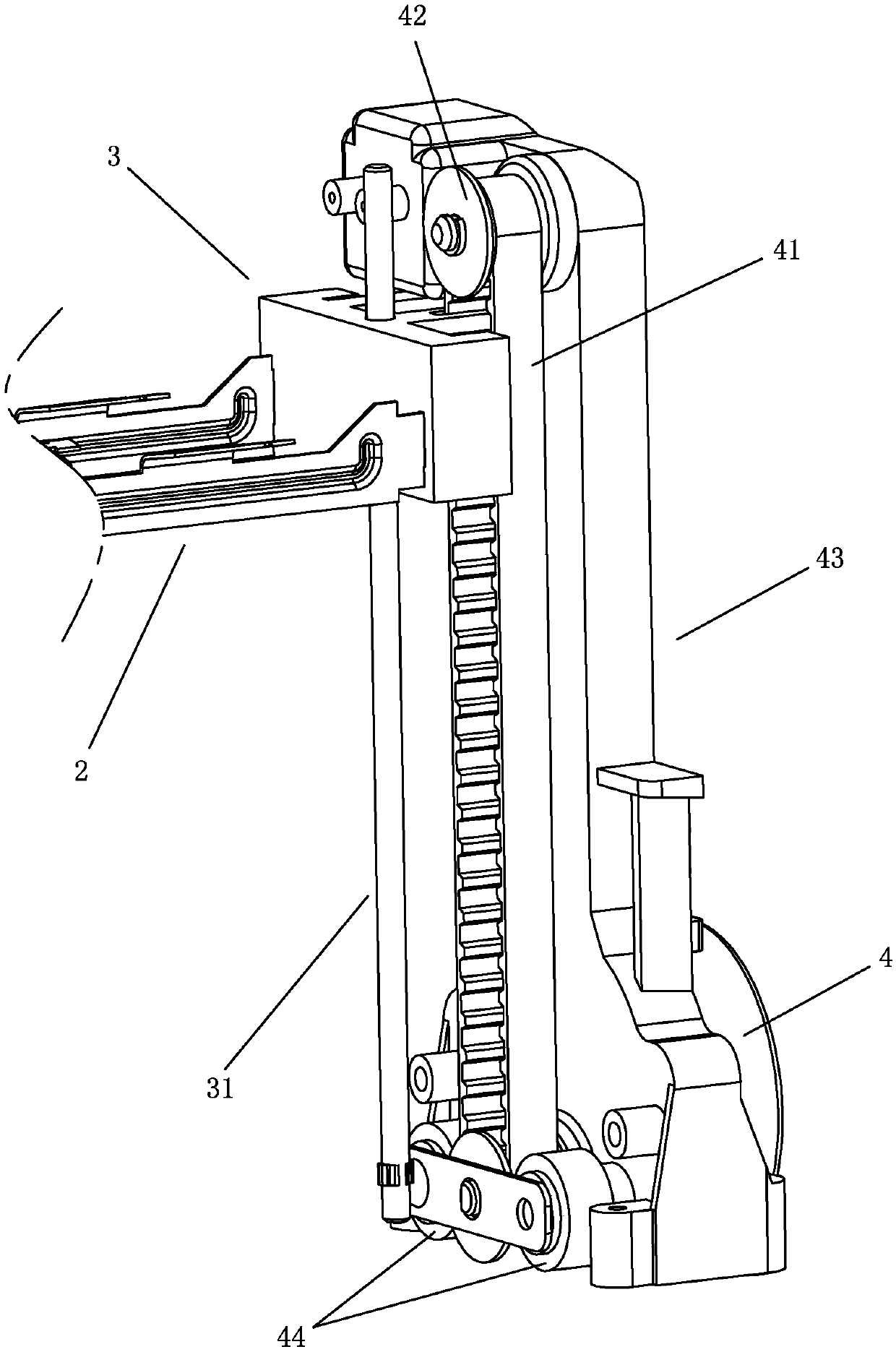

[0016] refer to Figure 1-Figure 4 , an automatic bread baker of the present invention, comprising a furnace assembly 5 in the furnace body, a heating element 1 and a bracket 2, the heating element 1 is provided with a heating wire 14, and the bracket 2 is movably positioned In the furnace assembly 5, one end of the bracket 2 is correspondingly passed through the furnace assembly 5 and is connected with a moving part 3. The moving part 3 is connected with a main transmission part 4 that drives the moving part 3 to rise and fall. The furnace assembly 5 is correspondingly provided with a relief bracket. The vertical limit slot of the frame 2, during the toasting process, the main transmission part 4 drives the moving part 3 through a vertical screw, piston cylinder or other mechanisms to make the bread slices move up and down automatically, so that the bread slices can pass through the moving More evenly absorb the heat emitted by the heating element 1 for heating. The heating e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com