Stretcher and high-precision stretching method for secondary screen printing plate

A high-precision, printing screen technology, applied in printing, printing plate preparation, etc., can solve the problems of low screen overprint accuracy, inability to fine-tune the steel wire mesh, and alignment deviation, etc., to improve photoelectric conversion efficiency, improve printing accuracy, The effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

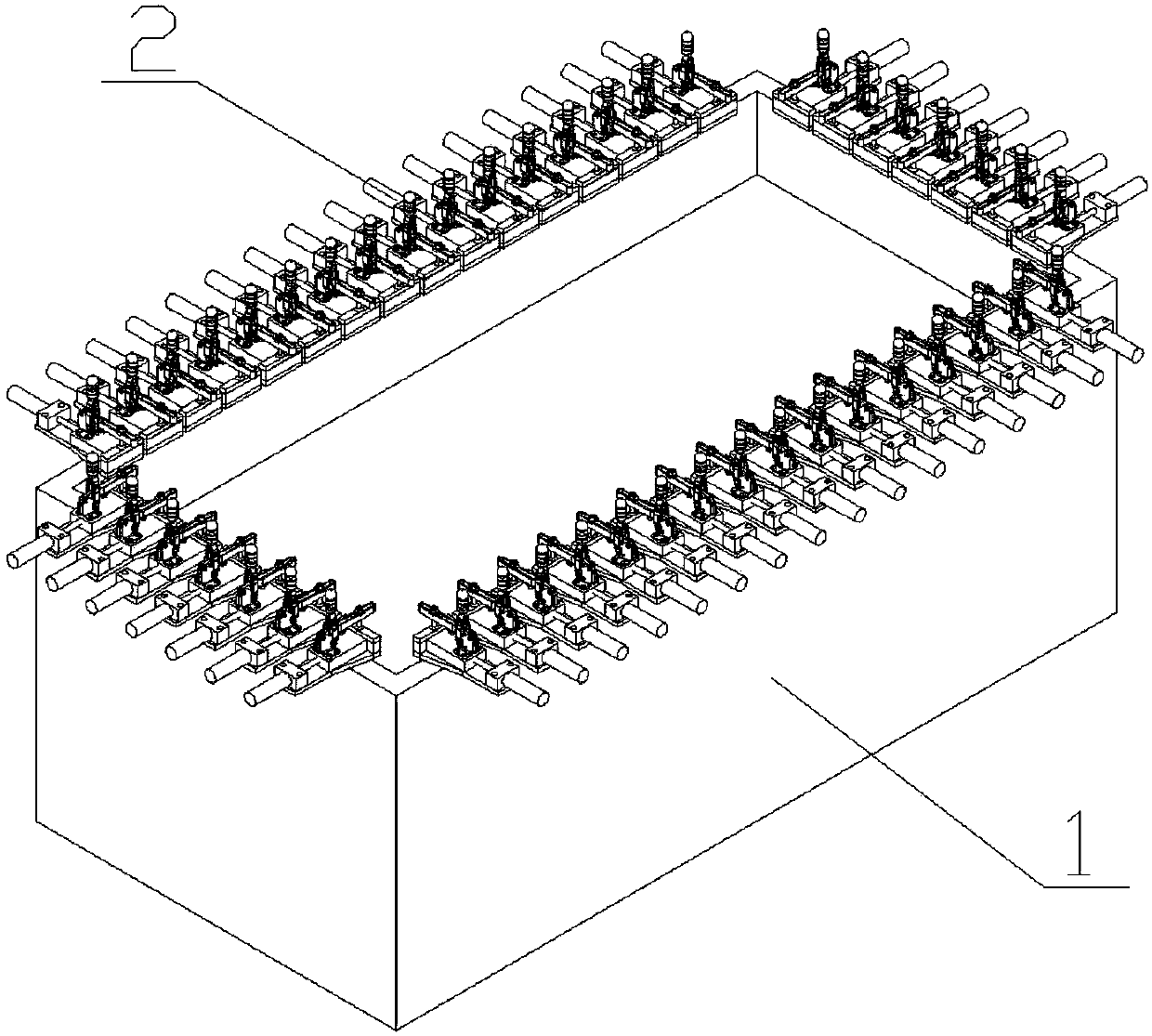

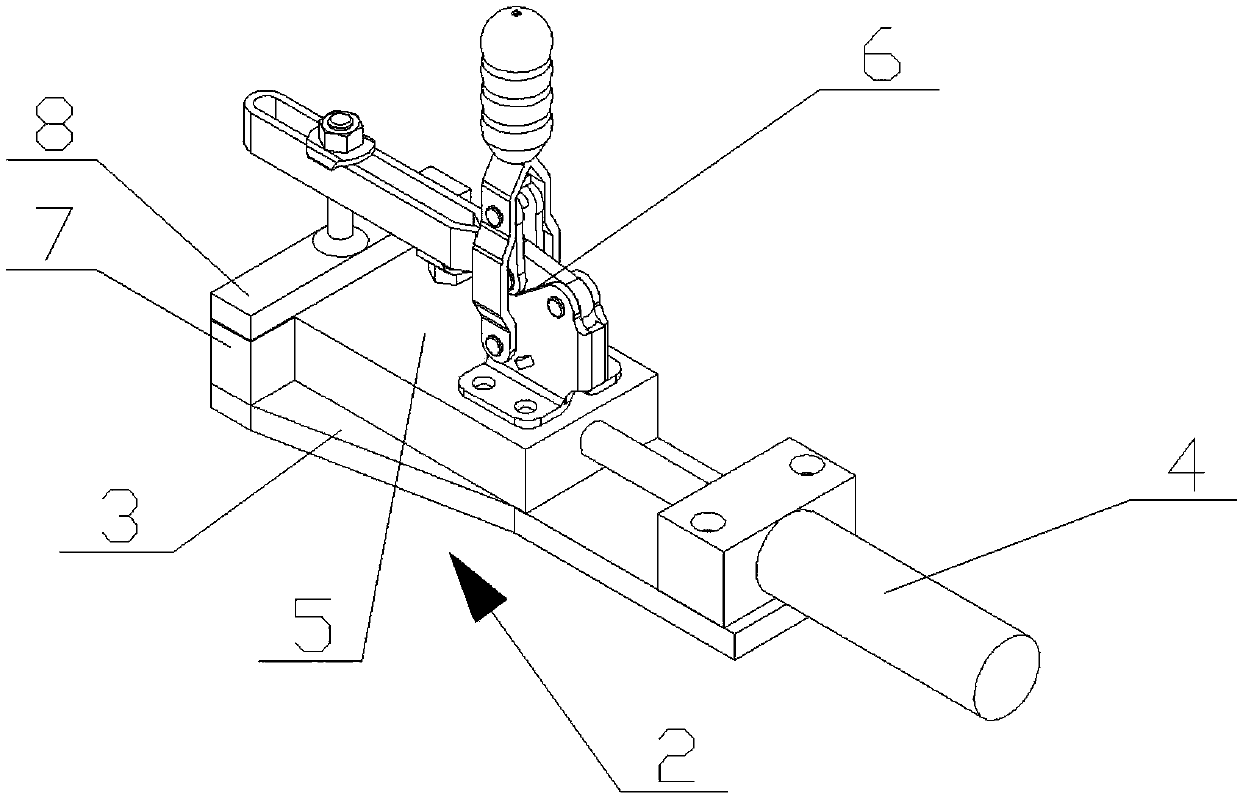

[0019] Such as Figure 1 to Figure 2 As shown, a net stretching machine includes a platform 1 and a plurality of clamping devices 2 installed on the platform 1 to independently clamp the wire mesh. The clamping device 2 includes a fixed plate 3 fixed on the table body 1, a linear drive mechanism 4 installed on the fixed plate 3, a sliding plate 5 slidably connected with the fixed plate 3, a quick clamp 6 installed on the sliding plate 5, And the first clamping plate 7 and the second clamping plate 8 respectively arranged on the sliding plate 5 and the quick clamp 6.

[0020] The sliding plate 5 is connected with the driving head of the linear driving mechanism 4 , and is driven by the linear driving mechanism 4 to move linearly to adjust the position of the sliding plate 5 on the fixed plate 3 . L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com