Printing method for solving printing ink feeding stopping problem of silk screen printing

A printing method and screen printing technology, applied in printing, printing device, optics and other directions, can solve the problem of oil-free and other problems, and achieve the effects of less material waste, improved printing quality and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

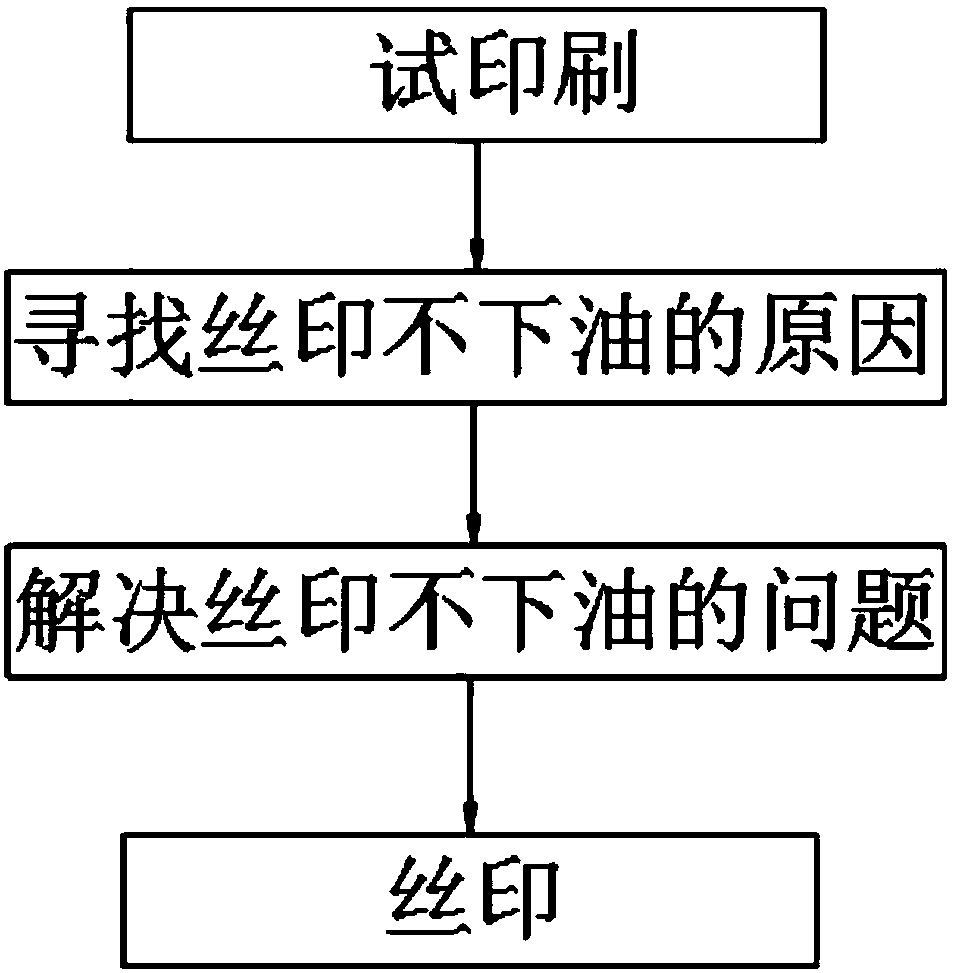

[0021] Example: such as figure 1 As shown, the present invention provides a method for solving the problem of silk screen printing without oiling, comprising the following steps:

[0022] 1) Trial printing: The first step is trial printing with white glass, and a screen printing machine is provided. The printing platen of the screen printing machine includes the substrate, the first moving guide rail, the second moving guide rail and the moving plate, the first moving guide rail and the second moving guide rail. The two moving guide rails are perpendicular to each other and are fixed on the base plate, and the moving plate is movably arranged on the base plate through the first moving guide rail and the second moving guide rail; the glass to be screen-printed is fixed on the moving plate, and the printing table moves In this way, the glass is driven to move under the screen printing plate of the screen printing machine, and the glass is divided into the first corner area, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com