Multifunctional storage bin

A storage bin and multi-functional technology, which is applied to fruit hanging devices, horticulture, and botanical equipment and methods, can solve the problems of low efficiency, high cost, and inability to realize the diversification of stored grains, so as to save land resources and reduce Construction cost, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

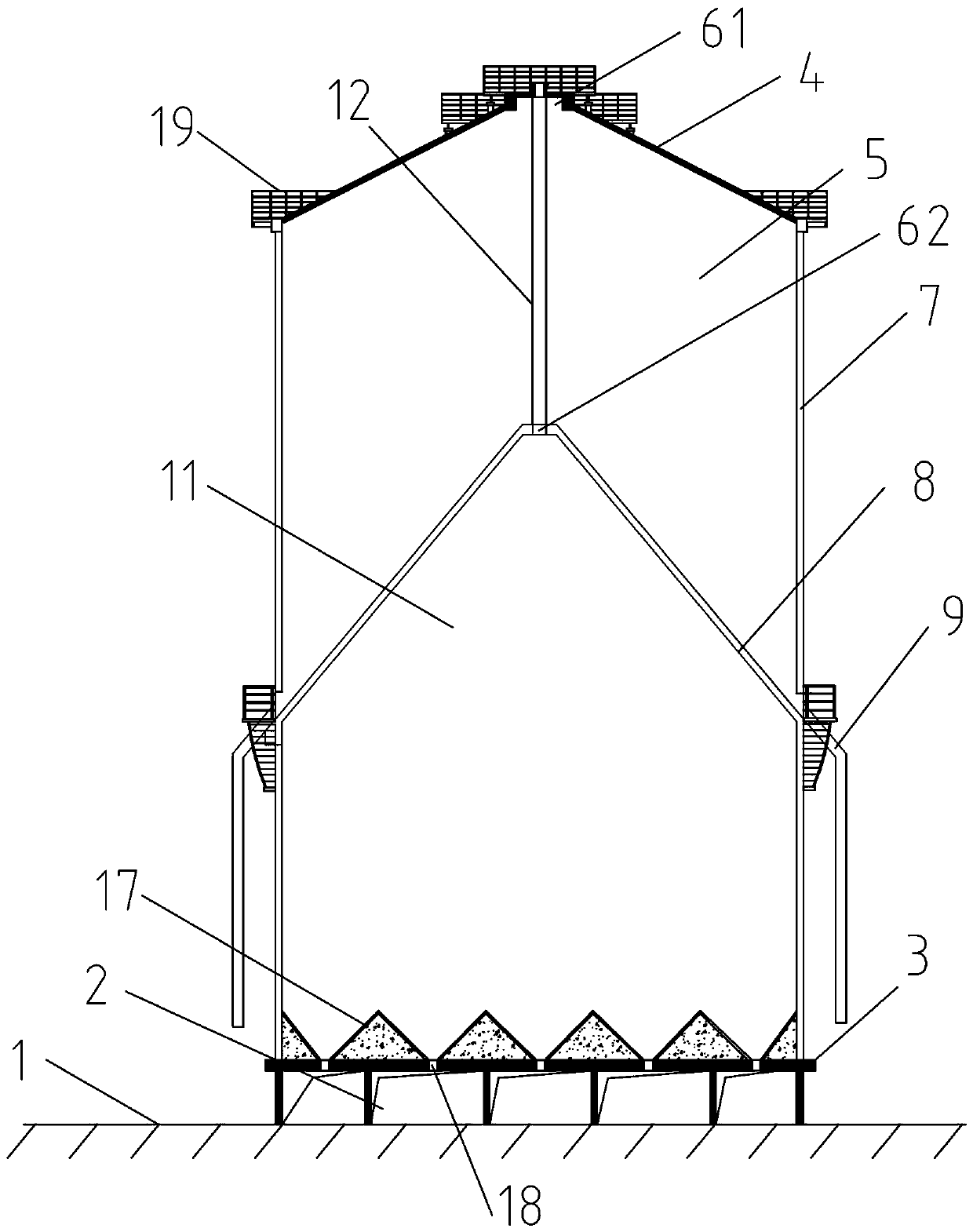

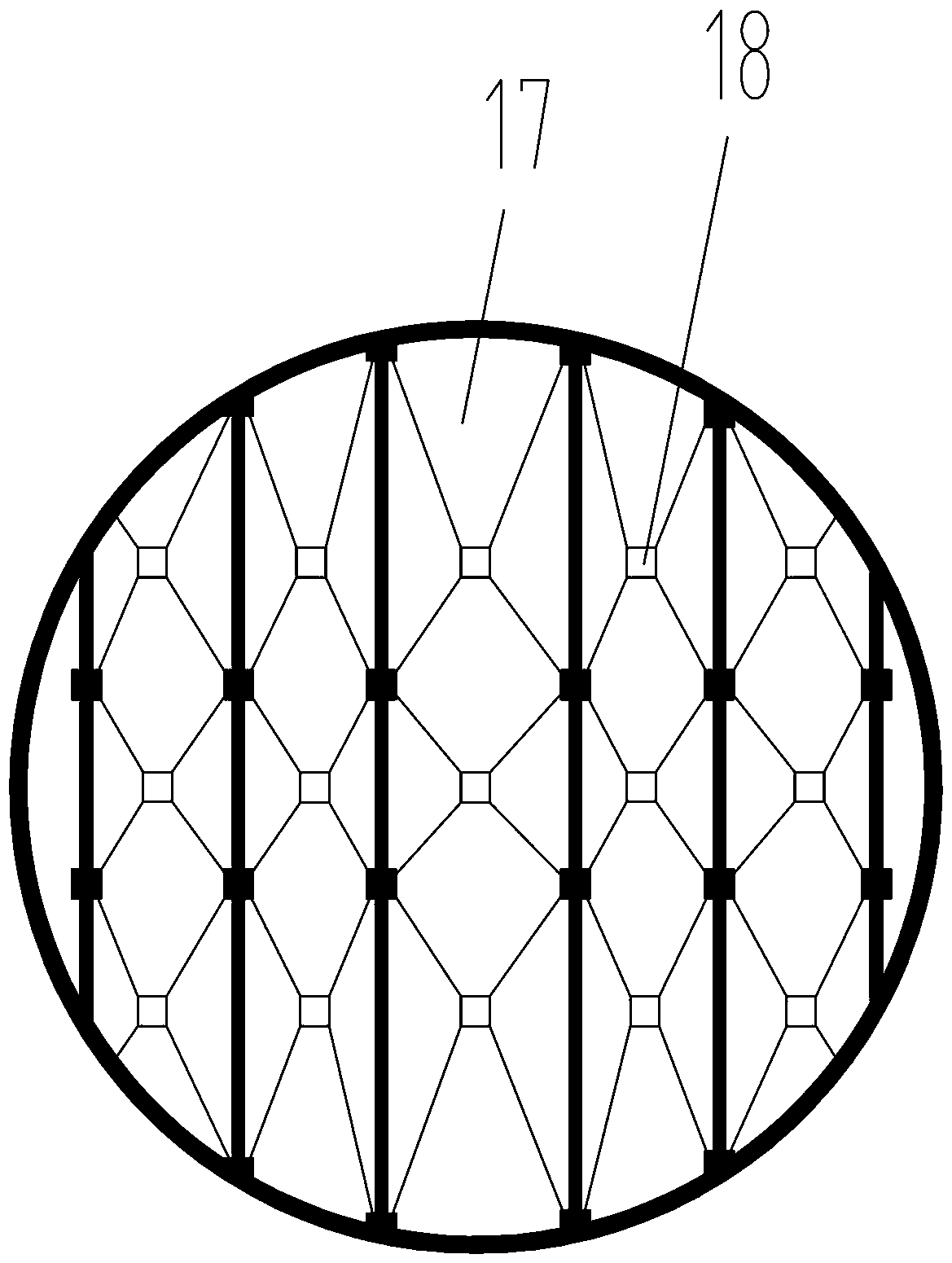

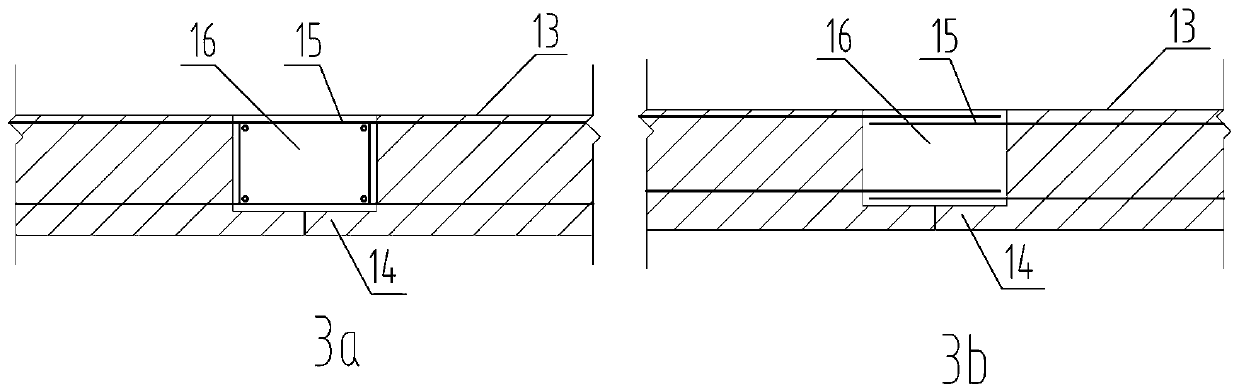

[0047] Such as figure 1 and 2 As shown, the present invention is a columnar structure as a whole, comprising an upper warehouse 5, a lower warehouse 11, a warehouse bottom 3, a warehouse cover 4, a warehouse wall 7, an intermediate spacer 8, and a support member 2; Layer 8 and warehouse wall 7 are enclosed, and the first feeding hole 61 is set on the warehouse cover 4; the lower warehouse 11 is surrounded by the middle interval layer 8, warehouse wall 7, and warehouse bottom 3; the warehouse bottom 3 is above the ground 1 , the support member 2 is used to support the bottom of the warehouse 3; the bottom of the warehouse is provided with a plurality of inverted cone funnels 17 formed by filling slopes, and the lower end of the inverted cone funnels 17 is provided with a discharge hole 18, and the junction of the warehouse wall 7 and the middle interlayer 8 The upper part is provided with an outlet of the upper warehouse, and the outlet of the upper warehouse is provided with ...

Embodiment 2

[0056] The general structure of this embodiment is the same as that of Embodiment 1, the difference is that: Figure 4 As shown, two partitions 20 are set in the upper warehouse 5, the partitions 20 have the same shape and structure as the middle spacer layer 8, and the third feed hole 63 is set at the top of the taper surface of the partition 20. By adding a feed sleeve The pipe realizes the feeding between the first feeding hole 61 and the third feeding hole 63, and the position of the warehouse wall 7 close to the partition 20 is provided with a discharge hole, and the discharge hole is provided with a pipe 21 leading to the ground.

Embodiment 3

[0058] The general structure of this embodiment is the same as that of Embodiment 1, the difference is that: Figure 5 and 6 As shown, the auxiliary warehouse 10 is provided outside the lower warehouse 11. The auxiliary warehouse 10 includes an auxiliary warehouse wall 102, an auxiliary warehouse bottom 101 and an auxiliary warehouse roof 103. The auxiliary warehouse roof 103 is provided with an auxiliary warehouse inlet 104. The bottom of the warehouse 101 is provided with an auxiliary warehouse outlet 105; above the junction of the warehouse wall 7 and the intermediate layer 8, an upper warehouse outlet is arranged, and the upper warehouse outlet and the auxiliary warehouse inlet 104 are connected by a slide pipe 9;

[0059] The outlet of the upper warehouse and the outlet of the auxiliary warehouse are respectively provided with a discharge switch K1 and a discharge switch K2; when the discharge switch is turned on, the material in the corresponding warehouse can flow out. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com