Polyester fiber production equipment

A polyester fiber and production equipment technology, which is applied in the field of polyester fiber production equipment, can solve problems such as insufficient supply, lack of design experience, and large gaps in car interiors, and achieve the effect of convenient operation and transportation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

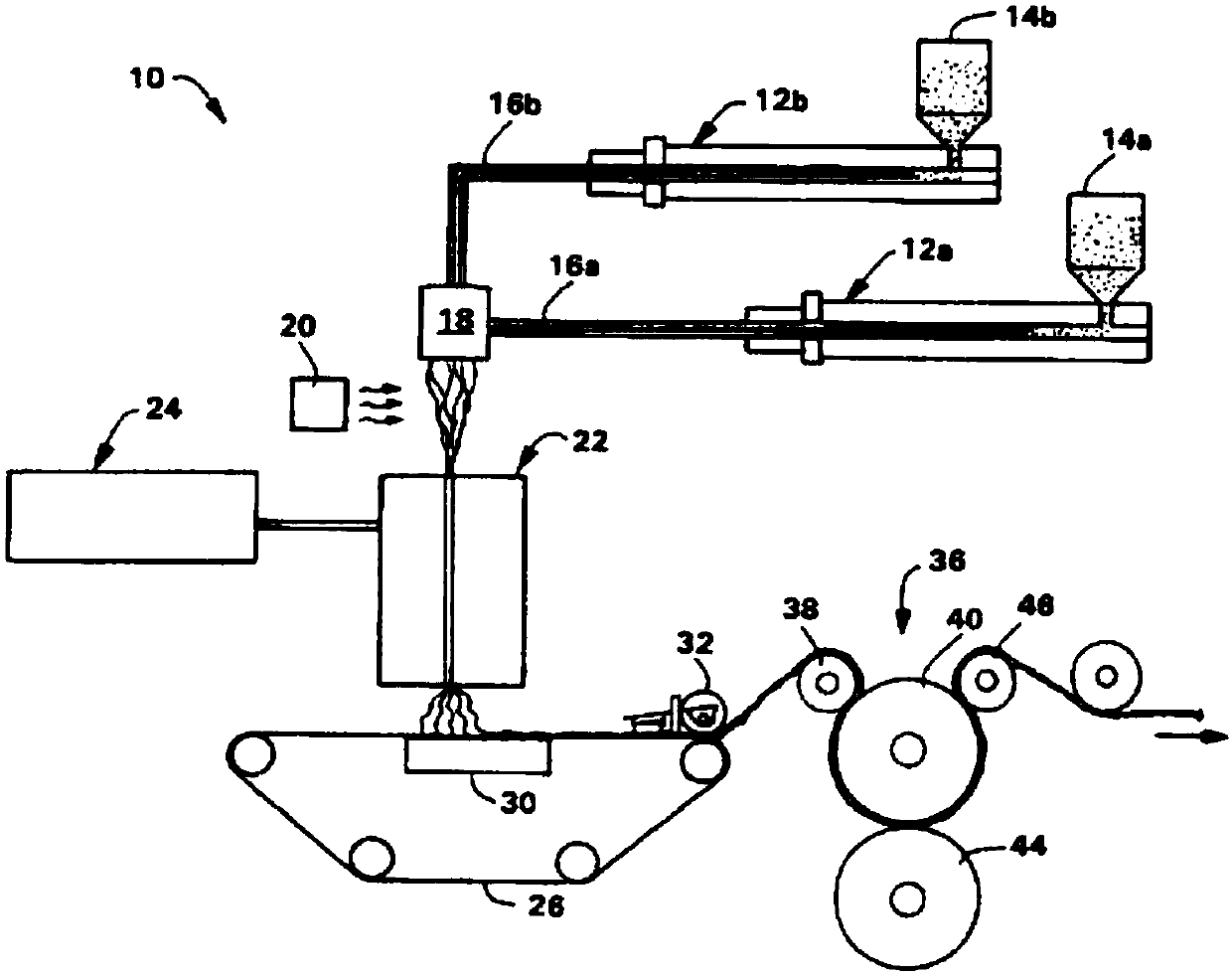

[0023] see figure 1 , shows a schematic diagram of the production equipment of the polyester fiber of the present invention.

[0024] Wherein, the polyester fiber is composed of different polyester fibers, including at least a first polyester fiber and a second polyester fiber.

[0025] For producing this polyester fiber, production equipment 10 of the present invention comprises the first fiber extruder 12a, the second fiber extruder 12b, the first fiber feeder 14a, the second fiber feeder 14b, spinneret 18, conveying Belt 26 , press rolls 32 and thermoforming equipment 36 .

[0026] Wherein, the first fiber feeder 14a is positioned at one end of the first fiber extruder 12a, and the first fiber feeder 14a is provided with a heating device (not shown), and the first polyester fiber is heated and melted by the heating device after being heated and melted by the first fiber feeder. A fiber feeder 14a feeds the first fiber extruder 12a; the second fiber feeder 14b is positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com