Bridge construction method

A technology of bridge construction and steel strands, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of protracted construction period, repeated construction, large errors, etc., and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

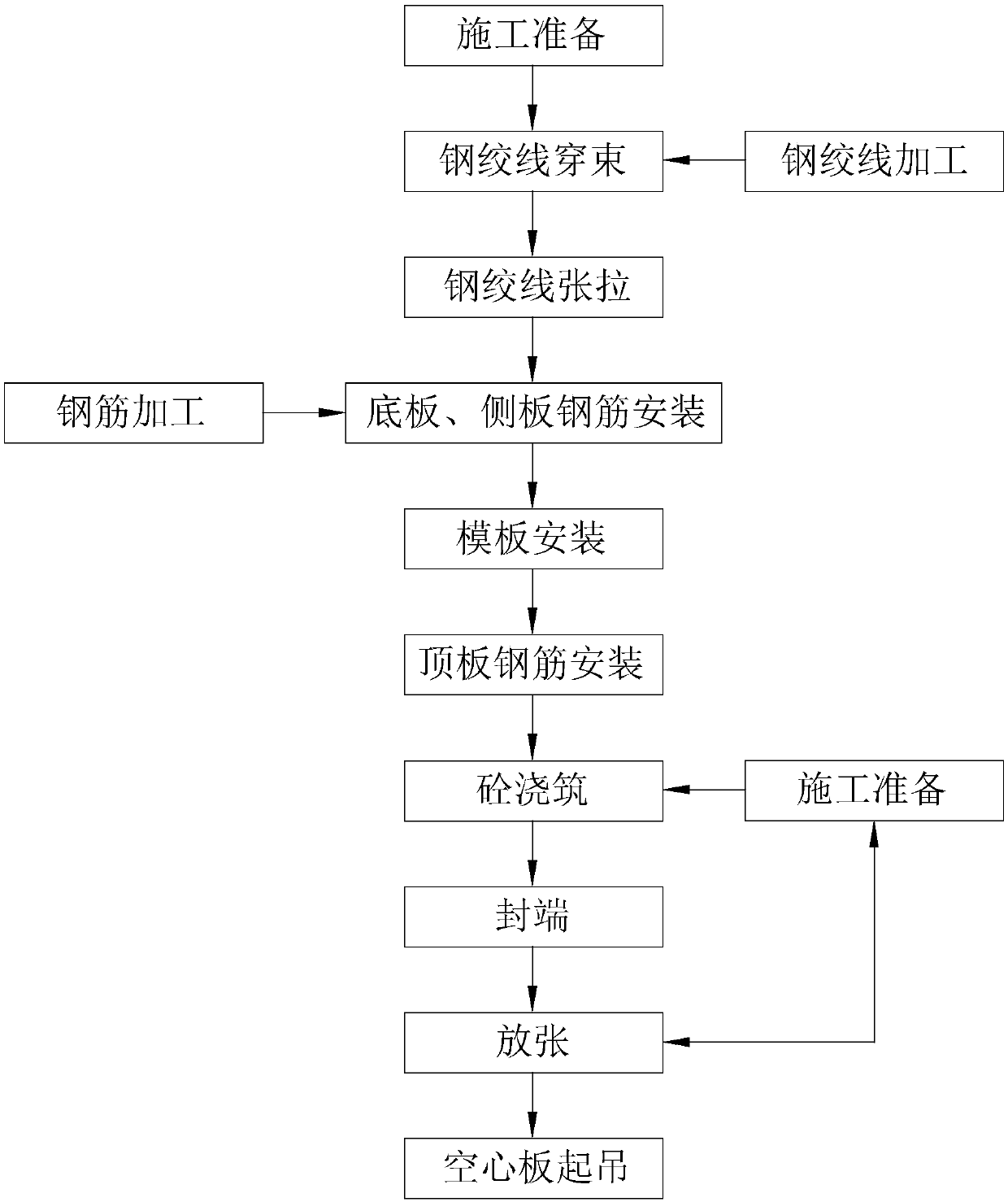

[0084] A bridge construction method, including pier column construction, hollow slab construction, hollow slab hoisting, scaffold erection, high-support formwork construction, and concrete construction, wherein each construction project is started in time-sharing or simultaneously when needed.

[0085] During the construction of pier columns, the construction of the pier body adopts steel pipe scaffolding next to the pier abutment, and the truck crane enters the construction area to cooperate with the construction of artificially erected large integral steel formwork. The truck pump is sent into the mould, and the distribution arm of the pump truck can also be directly extended from the air to the top of the pier and a string tube is added to pour the column concrete. The pier columns located on the central partition are all poured to the top at one ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com