A method of manufacturing corrugated metal hose with shock-absorbing function

A metal hose and metal bellows technology, applied in hoses, chemical instruments and methods, pipes, etc., can solve the problems of increased number of bellows, uncoordinated bellows, inconvenient installation and use, etc., to reduce loss and improve Shock absorption effect and accident prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

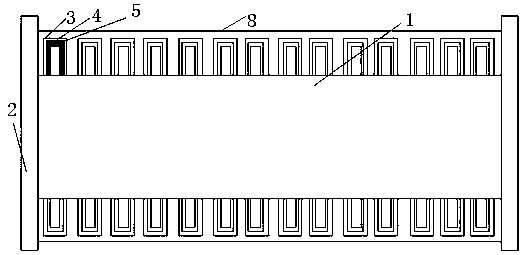

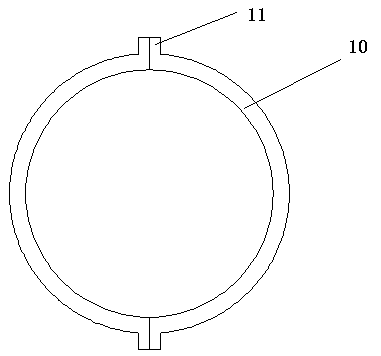

[0027] Such as figure 1 and figure 2 As shown, a corrugated metal hose with a shock absorbing function is shown, which includes an annular metal bellows 1 and joints 2 welded at both ends thereof. Metal jacket 3, said metal jacket 3 is welded by two semicircular snap rings 10, the two ends of the snap rings shown are respectively provided with a flat lug plate 11, said metal jacket 3 and annular metal bellows 1 A glass fiber cloth layer 4 is filled in between, and a metal mesh sleeve 8 is arranged outside the annular metal bellows 1, and the metal mesh sleeve 8 is welded and fixed to the joints 2 at both ends.

Embodiment 2

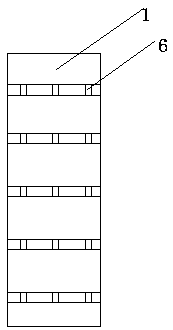

[0029] Such as image 3 and Figure 4 As shown, there is a rubber layer 5 on the outside of the peak position of the annular metal bellows 1, and the glass fiber cloth layer 4 is bonded to the outside of the rubber layer 5 by resin. The annular metal bellows 1 and the metal jacket 3 The gaps in between are filled by the rubber layer 5 . The crest of the annular metal bellows 1 is provided with a plurality of notches 6, the inner side of the rubber layer 5 is provided with a groove 9 wrapping the crest, and the groove 9 is provided with a plurality of notches to cooperate with the notches. The raised 7.

[0030] A method for producing a corrugated metal hose with a shock-absorbing function, the specific steps are as follows:

[0031] 1) A plurality of notch groups are pressed along a straight line on multiple crests of the annular metal bellows 1, so that the notches 6 between each row of crests are aligned in a straight line, and the number of notch groups is not less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com