A load concrete high temperature impact test furnace

An impact test, concrete technology, applied in furnace, furnace cooling, furnace type and other directions, can solve the problems of distortion and long time, and achieve the effect of high scientific research application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

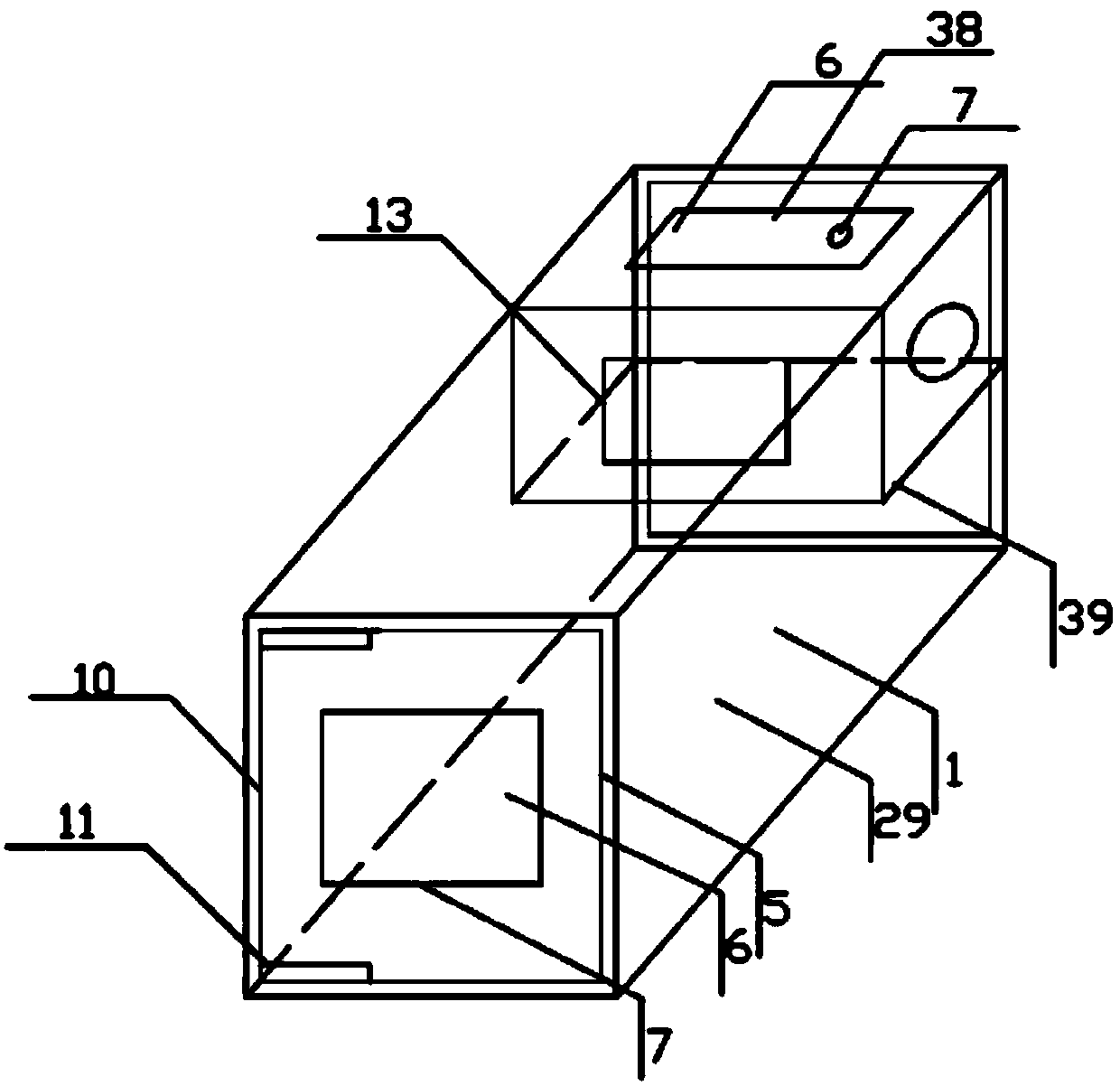

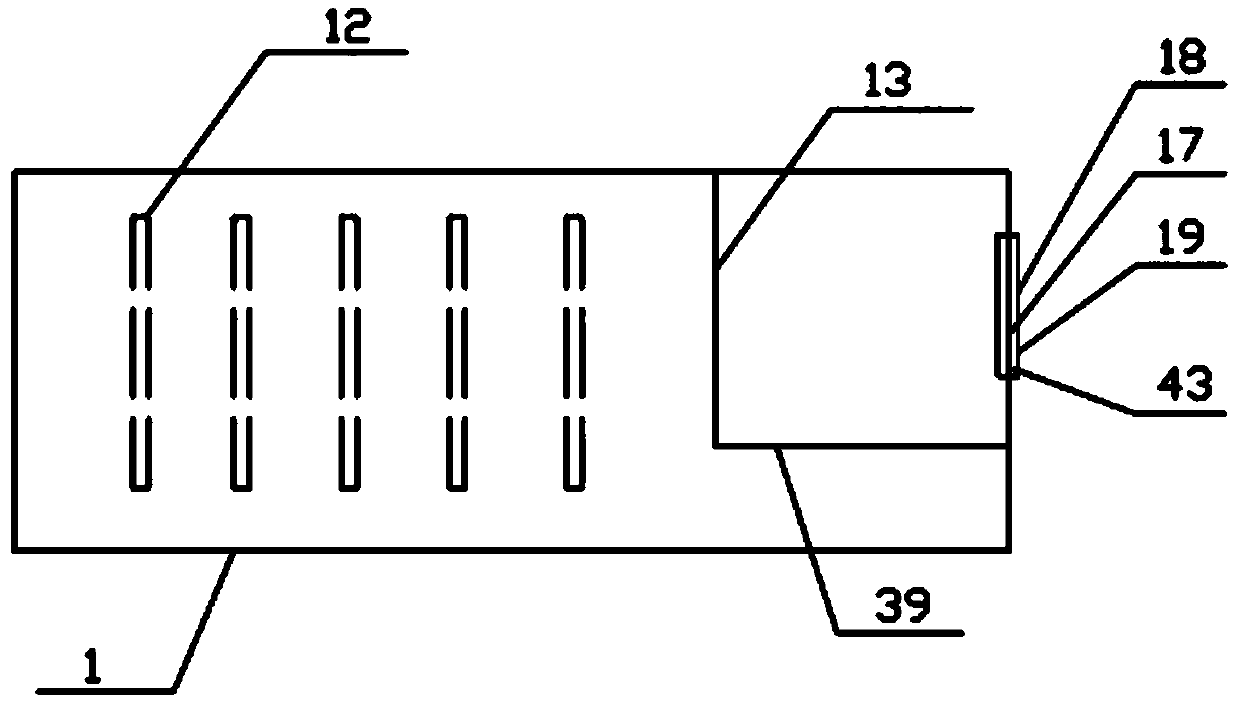

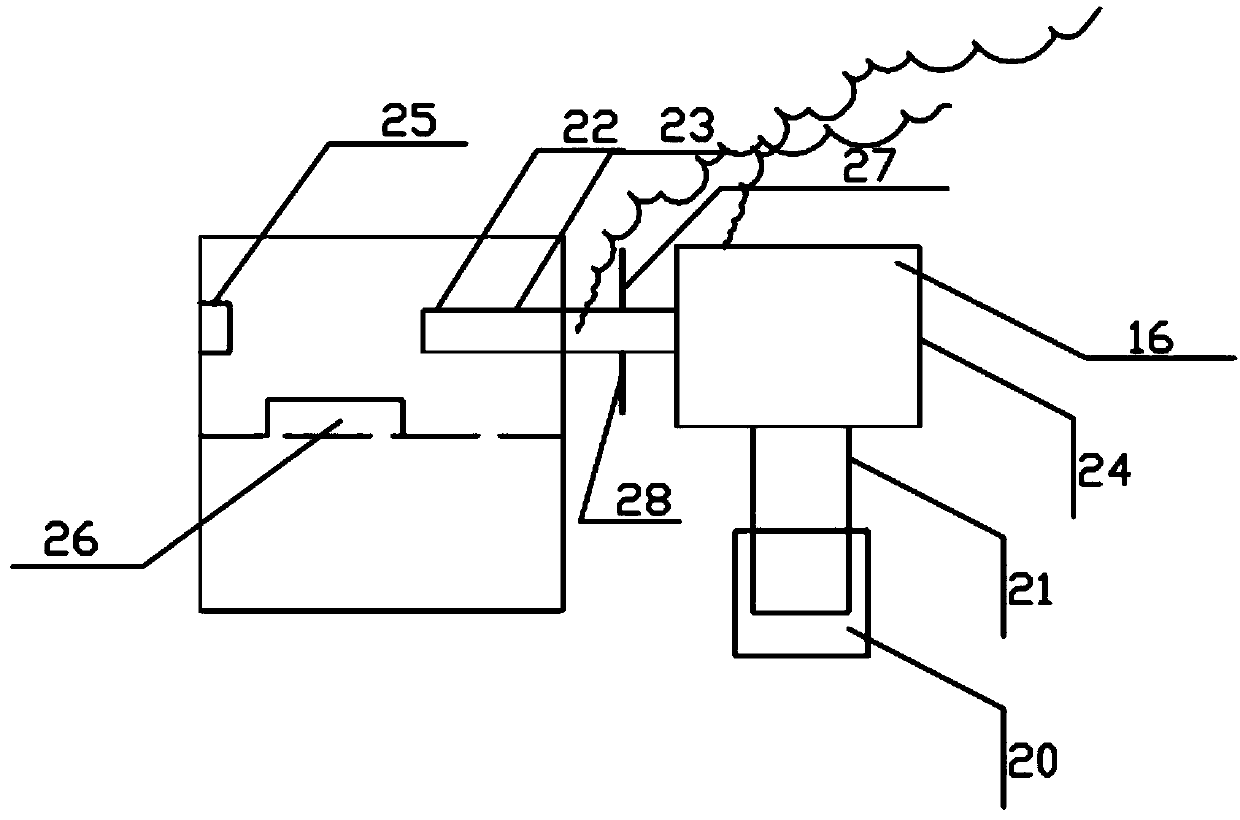

[0028] A load concrete high-temperature impact test furnace, including a shell 1, which also includes a high-temperature chamber 29, a test chamber 39, a loading device 16, a temperature self-balancing system and a control unit, and the high-temperature chamber 29 is arranged in the inner cavity of the shell 1 side by figure 1 and Figure 4 It can be seen that the shell 1 of the device is welded by 2mm steel plate 2, and the fire-resistant, corrosion-resistant, acid- and alkali-resistant paint 3 is sprayed on both sides of the steel plate, and the main material of the furnace lining is refractory brick 4, which is built on the steel plate 2 The inner side of this makes the device heat-preserving and durable, and the high-temperature chamber door 5 is arranged on the end of the high-temperature chamber 29, such as Figure 7 In the detailed drawing, the high-temperature chamber door 5 of the device is made of the same material as the furnace body, and a high-temperature-resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com