Method of microwave dehydrogenation for producing sodium oxalate

A technology of sodium oxalate and dehydrogenation, applied in the field of organic chemical industry, can solve the problems of affecting yield, high labor intensity of workers, and high flue gas temperature, reducing the occurrence of side reactions, excellent product quality, and dehydrogenation conversion rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

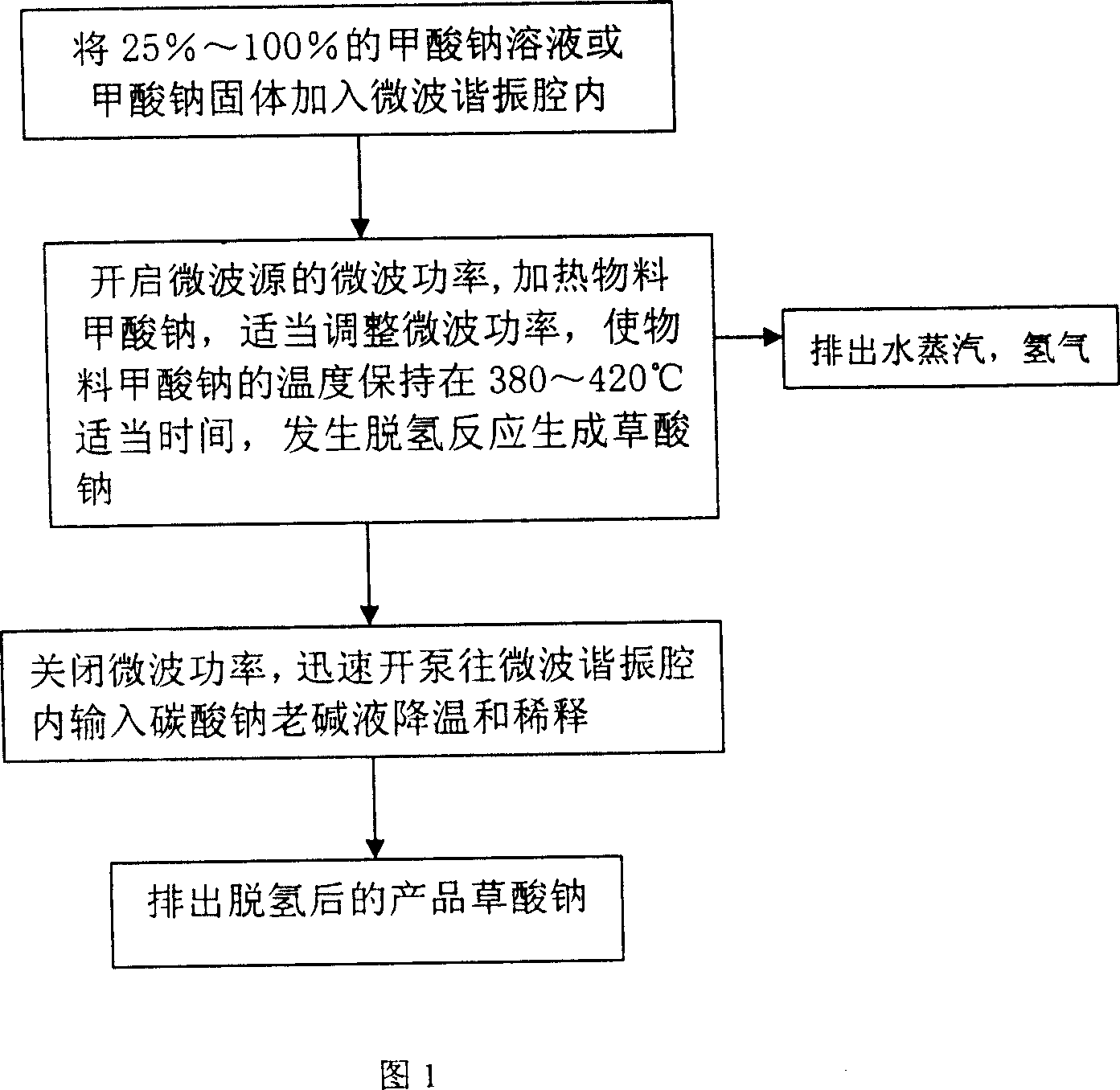

Image

Examples

Embodiment Construction

[0047]A single unit uses a 915MHz / 20kW microwave power source, connects the microwave transmission system and the microwave resonant cavity, puts 150kg of 75% sodium formate solution or sodium formate solid containing 2% NaOH as a catalyst into the microwave resonant cavity from the feeding port, and turns on the microwave source The microwave power is input into the microwave resonant cavity through the microwave transmission system to heat the sodium formate material. First, the full-power microwave is used for rapid heating. When the microwave power of the microwave source is turned on, the stirrer in the microwave resonant cavity is turned on to stir the material, and the material is heated for about 60 minutes. When the temperature of the sodium formate material reaches the dehydrogenation temperature of 380-420°C, the sodium formate becomes a molten state, and a dehydrogenation reaction occurs to generate sodium oxalate. Properly adjust the microwave power to keep the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com