Livestock feed cart and method of use thereof

A technology for feeding vehicles and livestock, which is applied in the field of livestock feeding vehicles to achieve a high degree of automation, uniform shovel, and the effects of mechanization and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

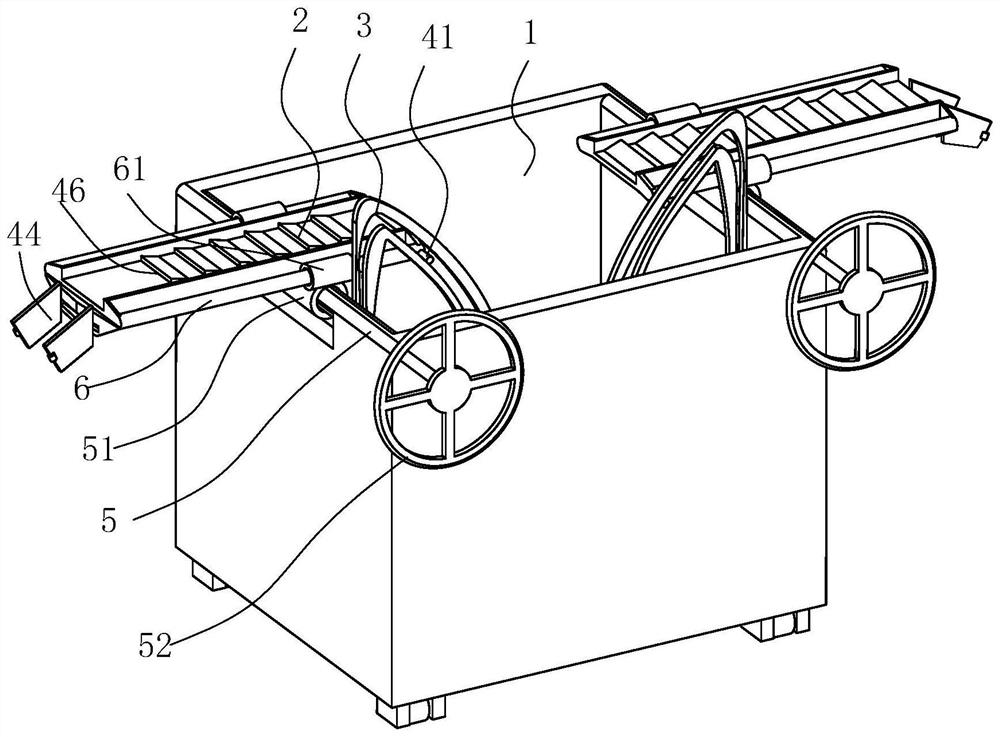

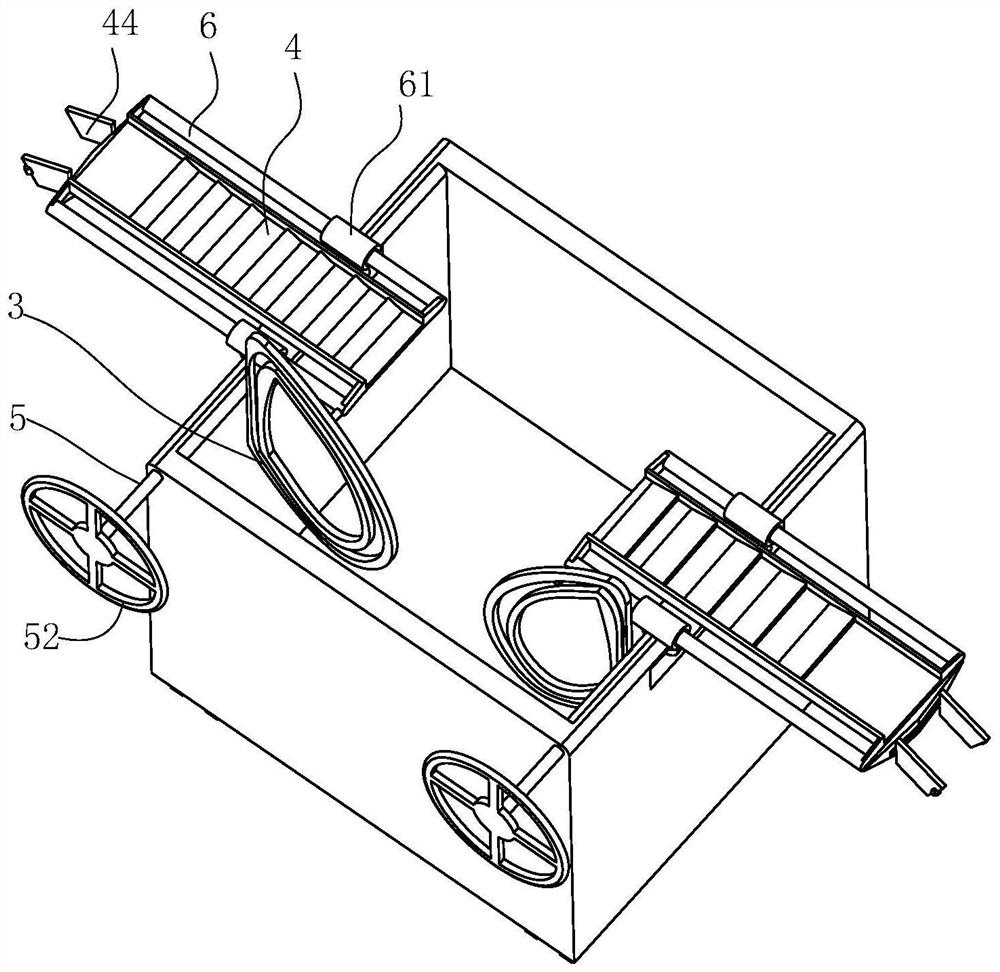

[0042] Such as Figure 1 to Figure 6As shown, the livestock feeding vehicle includes a compartment 1. The interior of the compartment 1 is a cavity structure for accommodating feed. The upper part of the compartment 1 is open, and a shoveling device 2 is installed on the left and right sides of the compartment 1, as mentioned above. Yes, there can be one shoveling device, or one on each of the left and right sides, or multiple on the side wall. The best solution is one on each of the left and right sides, so this patent introduces one on each of the left and right for convenience. The understanding of those of ordinary skill in the art allows those of ordinary skill in the art to know the specific working method. For the sake of clarity and simplicity, the structure and shape of the shoveling device 2 are the same. The structure and working method of the shoveling device 2 will be mainly described below.

[0043] The shoveling device 2 includes a rail 3 and a shoveling plate 4...

Embodiment 2

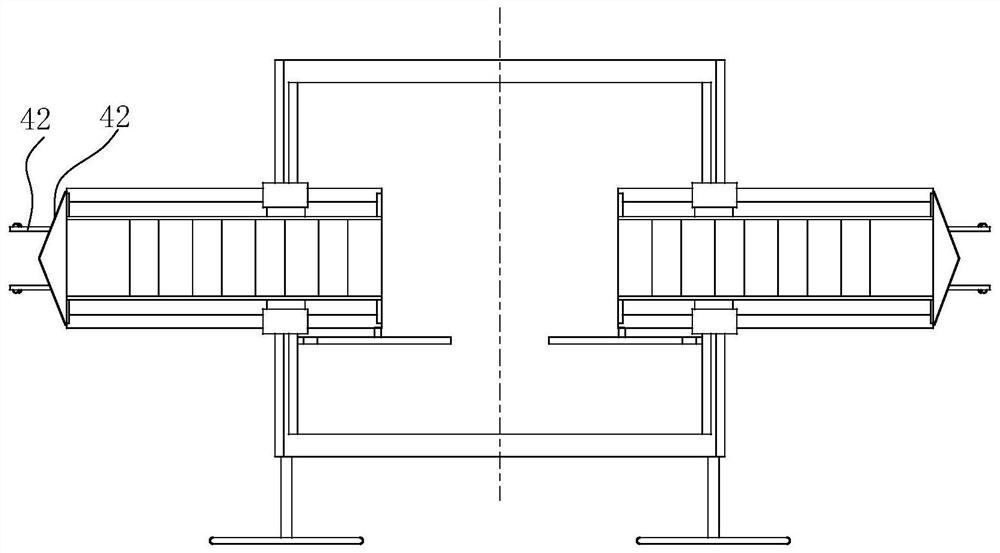

[0057] On the basis that the basic technical solution of Embodiment 1 remains unchanged, the driving mode of the driving wheel 51 to the shovel 4 adopts the following solution:

[0058] The driving wheel 51 is a gear, and the shoveling plate 4 is provided with a tooth track meshing with the driving wheel 51, and the tooth track extends along the length direction of the shoveling plate 4. When in use, the driving motor drives the driving wheel 51 to rotate by the rotating shaft 5, Driving wheel 51 utilizes rack and pinion transmission mechanism to drive scraping plate 4 to move left and right, and in this process, scraping plate 4 is owing to being subjected to the restriction of track 3, realizes shoveling and turning over after feed is dumped in the trough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com