Resin rope fastener with function of electromagnetic radiation resistance and production process of resin rope fastener

An anti-electromagnetic radiation and functional technology, applied in the field of plastic products, can solve the problems of no anti-radiation effect, poor anti-radiation effect, and single structure of plastic rope buckles, so as to enhance anti-radiation function, reduce friction, avoid fluffing or Fracture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

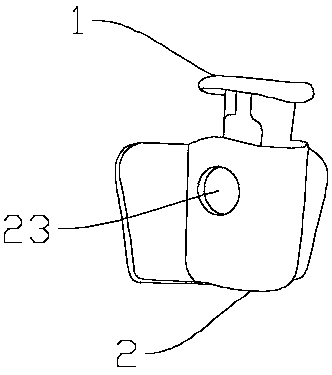

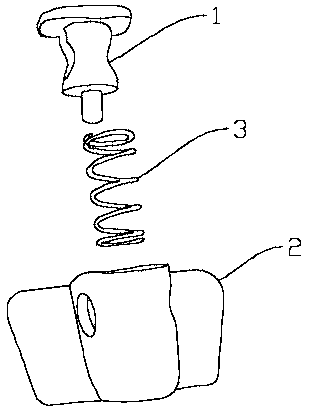

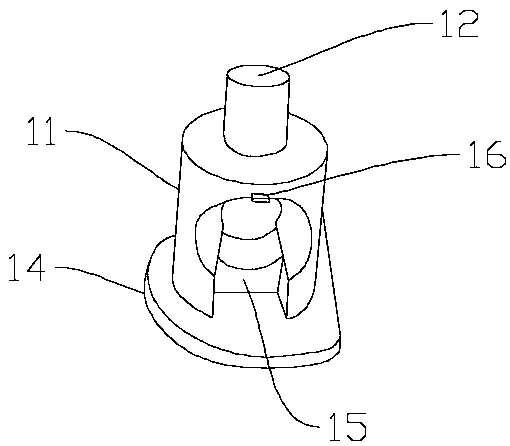

[0036] refer to Figure 1-4 , the present invention provides a resin rope buckle with anti-electromagnetic radiation function, comprising a male button body 1, a female button body 2 and an elastic member 3 connecting the male button body 1 and the female button body 2, the male button body 1 The elastic part 3 can be inserted into the female button body 2. The male button body 1 and the female button body 2 are made of radiation-proof materials. The male button body 1 and the female button body 2 include the following raw materials in mass percentage: 50% PTFE, 30% polyimide, 10% camellia oil, 10% silver powder.

[0037] Wherein, the female button body 2 includes a body 21, a cavity 22 for accommodating t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com