Electromagnetic radiation resistant APET rubber piece

An anti-electromagnetic radiation and film technology, applied in coatings, layered products, synthetic resin layered products, etc., can solve problems such as the impact of electronic product performance, and achieve unique efficacy, improved performance, and high interlayer bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

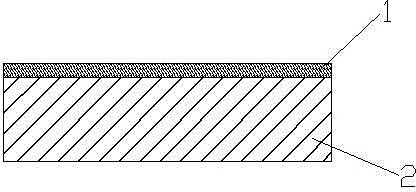

Image

Examples

Embodiment

[0019] The concrete preparation process of the anti-electromagnetic radiation APET film that the present invention mentions is as follows:

[0020] a) Material selection and preparation, the main components of the surface layer and their percentage ratios are: film-forming resin 45%, tourmaline powder 35%, solvent 12%, and the rest are related additives; among them, the film-forming resin is acrylic resin, electrical The average particle size of the stone powder is about 6-8um, the solvent is butyl ester, the additives include dispersant sodium pyrophosphate, coagulant hexyl silicate, antioxidant 1010, etc.; the substrate layer is made of APET sheet, and its thickness is about 0.2-0.22mm;

[0021] b) Prepare the surface coating, the preparation process is as follows: First, add the film-forming resin, solvent and antioxidant in the additive to the mixing tank, and stir thoroughly for 10-12 minutes; then, add tourmaline powder and the dispersion in the additive agent, fully st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com