3D printing gas tube bracket

A tracheal stent, 3D printing technology, applied in stents, medical science, prostheses, etc., can solve problems such as lung infection, intermittent suffocation, stent sliding, etc., to reduce the overall weight, easy to use, and strong support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

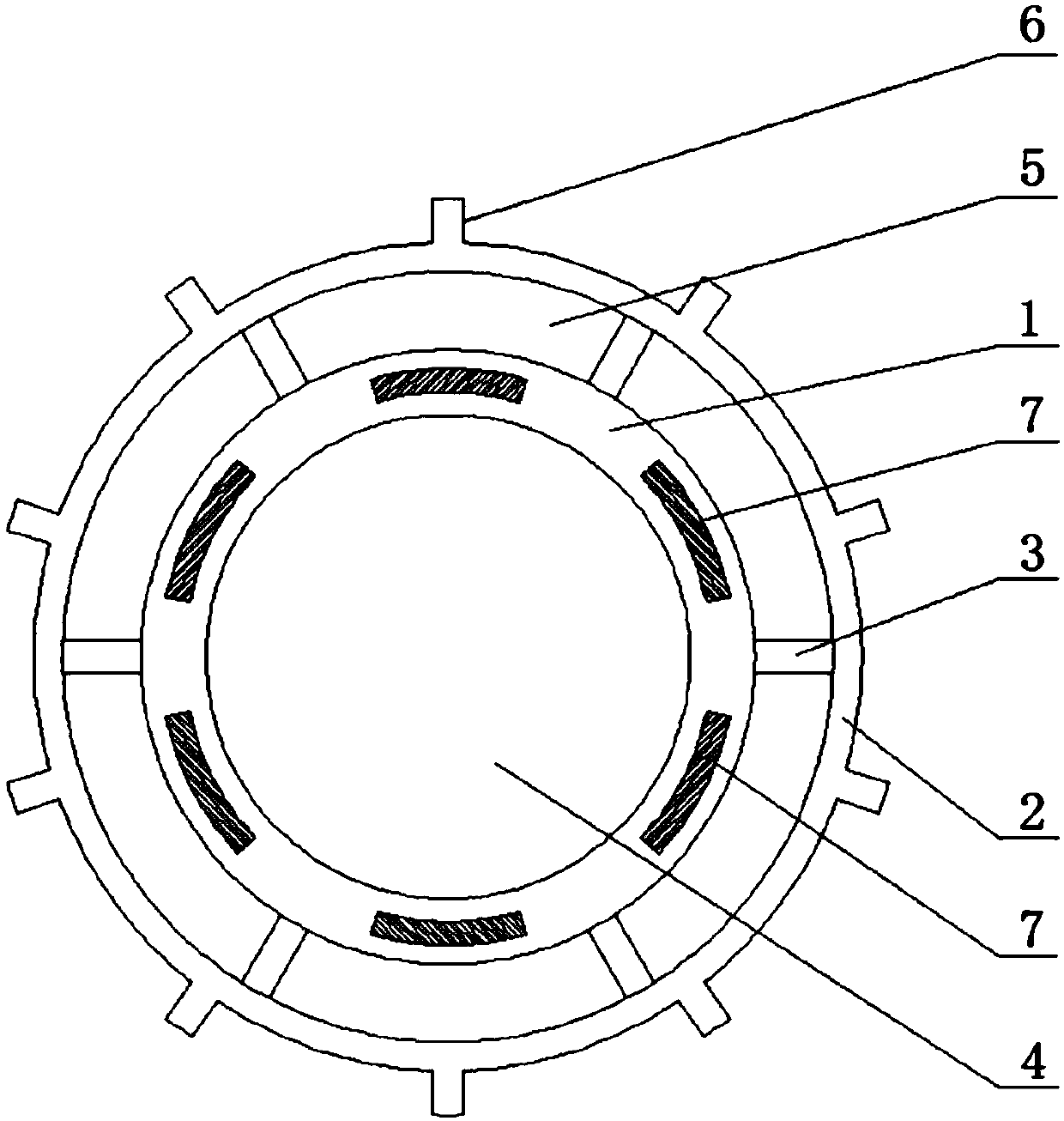

[0013] Such as figure 1 As shown, a 3D printed tracheal stent includes an inner stent 1 and an outer stent 2; the inner stent 1 and the outer stent 2 are both arranged as ring-shaped stents, and the outer stent 2 The outer diameter is larger than the inner layer bracket 1, and the thickness of the inner layer bracket 1 is larger than the outer layer bracket 2, and the inner layer bracket 1 and the outer layer bracket 2 are connected by evenly distributed support rods 3; The center of the inner stent 1 is set as a central trachea 4, and the gap between the inner stent 1 and the outer ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com