Detachable painting mist ventilating channel

A detachable, paint mist technology, applied in the direction of spraying devices, etc., can solve the problems of time-consuming, cumbersome installation, and difficult cleaning, etc., and achieve the effect of reducing labor intensity, improving production efficiency, and facilitating on-site operation for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

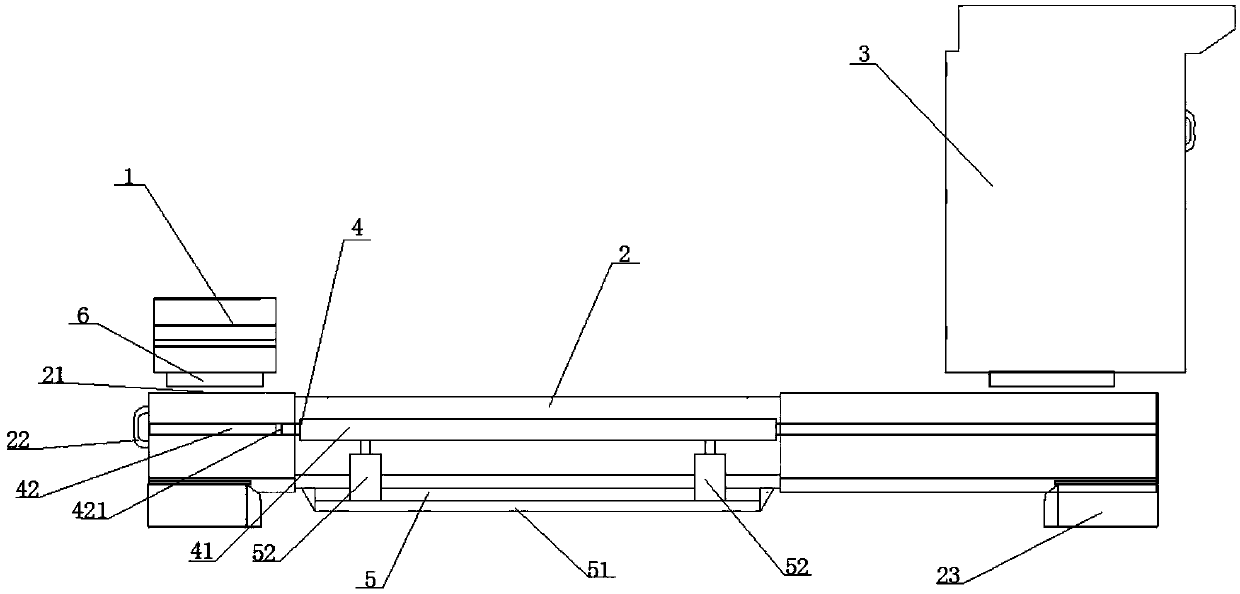

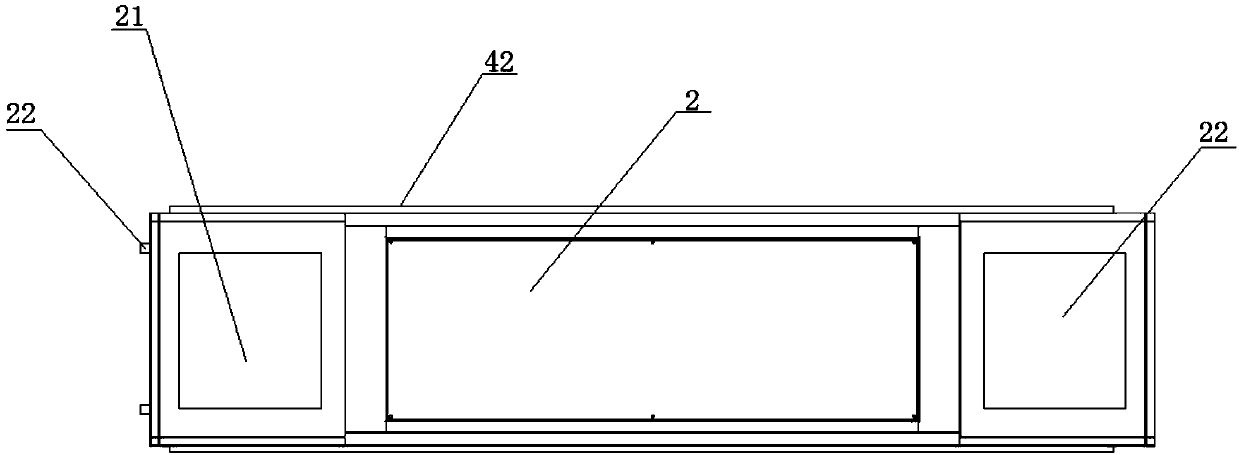

[0029] A detachable paint mist passage, including an air duct 2, one end of which is connected to the air inlet filter system 1 for sucking paint mist away, and the other end of the air duct 2 is connected to discharge paint mist to The exhaust filter system 3 in the air is characterized in that: a front and rear reciprocating device 4 and a vertical lifting device 5 are provided under the air duct 2, and two ends of the air duct 2 are provided for connecting the air duct 2 with the air inlet. The fixed automatic locking device of the filtering system 1 and the exhaust filtering system 3 also includes an intelligent controller, and the front and rear reciprocating device 4 and the vertical lifting device 5 are all electrically connected with the intelligent controller; Through the setting of the front and rear reciprocating motion device 4, the vertical lifting device 5 and the automatic locking device, after the entire passage is installed, it can be realized through external ...

Embodiment 2

[0031] On the basis of Embodiment 1, the vertical lifting device 5 includes a fixed bracket 51, and the fixed bracket 51 is provided with multiple groups of synchronous cylinders 52, and the output shaft of the cylinder 52 is provided with a front and rear reciprocating device 4, In this embodiment, the present invention realizes the vertical lifting of the air duct 2 through the setting of multiple sets of synchronous cylinders 52 and the function of the intelligent controller, so that the air duct 2 is easy to disassemble and achieves the purpose of facilitating on-site operation and cleaning by workers , Improve production efficiency and reduce labor intensity.

Embodiment 3

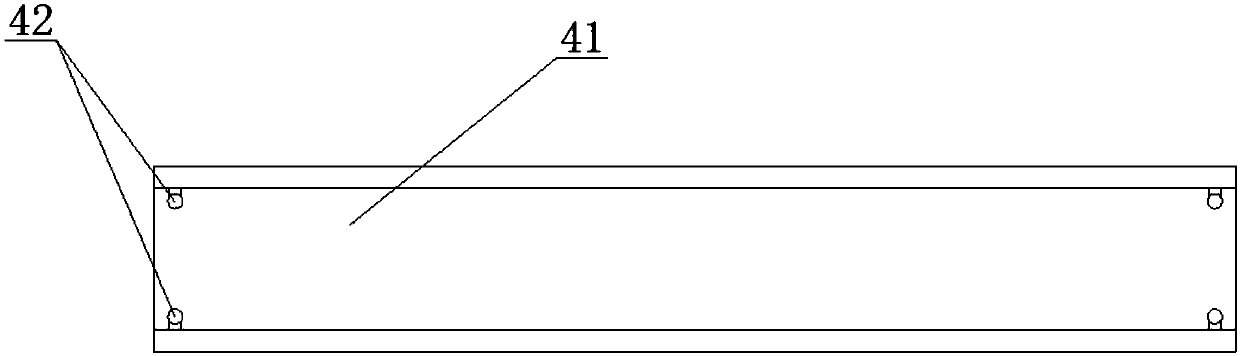

[0033] On the basis of Embodiment 1 or 2, the front and rear reciprocating device includes a chute 41 arranged on the output shaft of the cylinder 52, and a slide rail 42 is provided on the side wall of the air duct 2, and the slide rail 42 is located in the chute 41 and can move forward and backward along the length direction of the chute 41 . In this embodiment, the present invention realizes the forward and backward displacement of the air duct 2 by sliding the slide rail 42 in the chute 41, making the air duct 2 easy to disassemble, achieving the purpose of facilitating on-site operation and cleaning by workers, and improving the Production efficiency, reducing labor intensity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com