Water bar system adopting double circulation mode

A dual-circulation, mode technology, applied in multi-stage water treatment, non-polluting water treatment, water/sewage treatment, etc., can solve the problems of high TDS, short service life, poor RO membrane filtration effect of pure water, etc., to ensure stability Operation, ensure stable operation, improve purification efficiency and service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

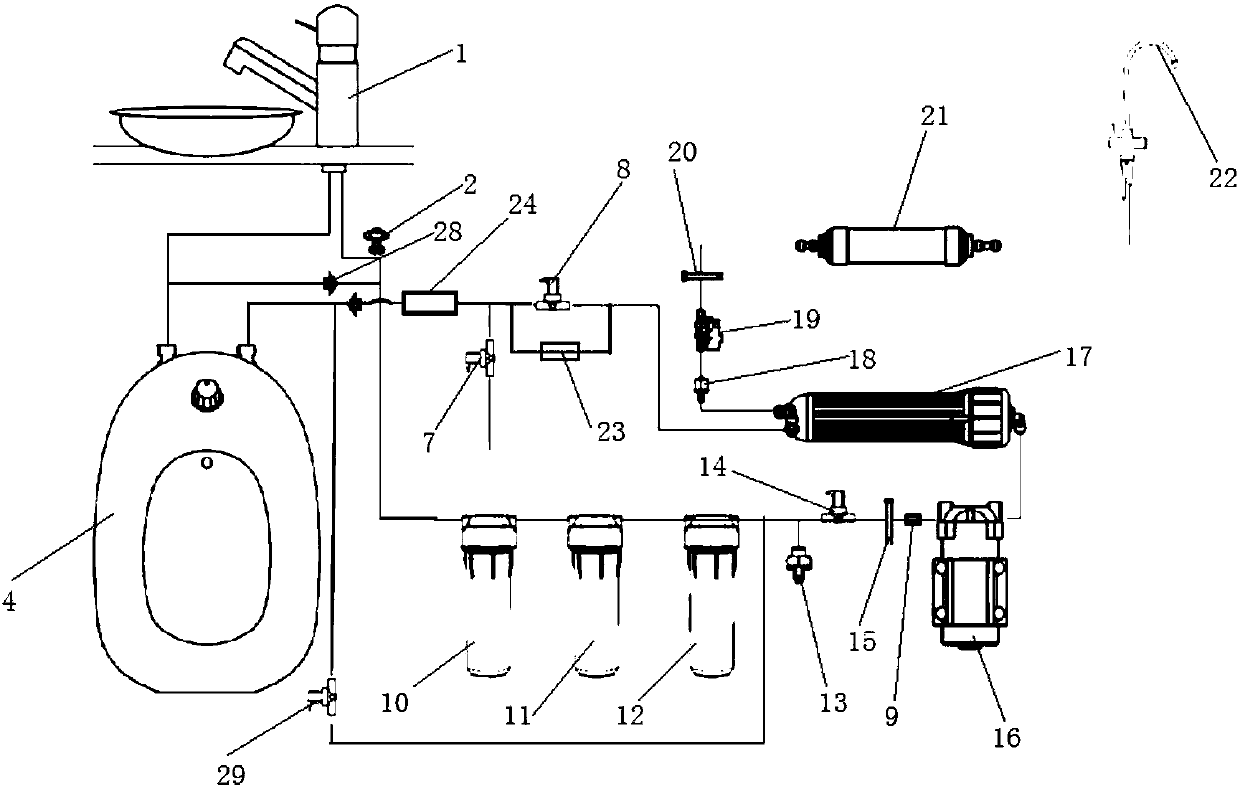

[0041] Such as figure 1 As shown, the water purification unit in this embodiment also includes a pre-filter and a post-filter 21, and the RO reverse osmosis filter is located between the pre-filter and the post-filter 21, wherein the pre-filter Including a first pre-filter 10, a second pre-filter 11 and a third pre-filter 12, the first pre-filter 10 filter element is a 5 micron melt-blown polypropylene filter element, the second pre-filter 11 filter element It is a granular activated carbon filter element, the third pre-filter 12 filter element is a 1 micron melt-blown polypropylene filter element, the post-filter 21 is an activated carbon filter, and the activated carbon filter is connected to a pure water faucet 22 through a pipeline .

Embodiment 2

[0043] When the user opens the pure water faucet 22, the system starts the water inlet solenoid valve 14 and the booster pump 16, and the tap water enters the pipeline from the tap water source 2, and passes through the first pre-filter 10 and the second pre-filter 11 in sequence , the third pre-filter 12, and then through the low-pressure switch 13, the water inlet solenoid valve 14, the water inlet TDS probe 15, the temperature sensor 9, and the booster pump 16 enter the RO reverse osmosis filter 17, and the filtered The pure water comes out of the pure water outlet of the RO reverse osmosis filter 17, passes through the pure water end check valve 18, the pure water end high pressure switch 19, the water outlet TDS probe 20, enters the post filter 21, and then passes through the pure water end The water tap 22 flows out into the water receiving container of the user. Since a large amount of concentrated water will be generated in the process of preparing pure water, the gener...

Embodiment 3

[0045] When the user turns on the hot water switch of the domestic faucet 1, the system starts the water inlet solenoid valve 14 and the booster pump 16, the flushing solenoid valve 8 is opened, and the tap water enters the pipeline from the tap water source 1, and passes through the first pre-filter 10, The second pre-filter 11, the third pre-filter 12, and then enter the RO reverse osmosis filter through the low pressure switch 13, the water inlet solenoid valve 14, the water inlet TDS probe 15, the temperature sensor 9, and the booster pump 16 In 17, it flows out from the concentrated water outlet, passes through the flushing solenoid valve 8 and the softening filter 24, enters into the kitchen treasure heater 4 through the water inlet of the kitchen treasure heater 4, and is heated in the kitchen treasure heater 4. After heating The water enters in the living faucet 28 through the water outlet of the kitchen treasure heater 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com