a soil stabilizer

A technology of soil stabilizer and waste concrete, which is applied in the field of building materials, can solve the problems of poor strength improvement of stabilized soil, etc., and achieve the effect of promoting agglomeration, large specific surface energy, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

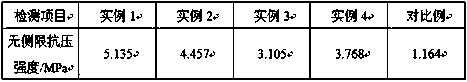

Examples

example 1

[0020] Add calcium alginate and water into a single-necked flask at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the single-necked flask into a digital speed measuring constant temperature magnetic stirrer at a temperature of 100°C and a speed of Under the condition of 500r / min, heat and stir to dissolve for 50min to obtain calcium alginate liquid; put the waste concrete in a ball mill to pulverize to obtain waste concrete powder; put waste concrete powder and calcium alginate liquid in a mass ratio of 1:50 In the No. 1 beaker, under the condition of rotating speed of 200r / min, stir and mix for 50min to obtain the concrete powder mixture, and then filter the concrete powder mixture to obtain the pretreated waste concrete powder; put the pretreated waste concrete powder in the muffle furnace , at a temperature of 900°C, calcined for 2 hours, and then lowered to room temperature with the furnace to obtai...

example 2

[0022] Put activated carbon and calcium hydroxide saturated solution in a No. 2 beaker at a mass ratio of 1:100, stir and mix for 50 minutes at a speed of 300r / min to obtain a mixed solution, and then continuously inject carbon dioxide into the mixed solution until mixed There is no precipitation in the solution, and then the mixed solution with carbon dioxide is filtered to obtain a filter residue, and the resulting filter residue and tetraethyl orthosilicate are placed in a No. 3 beaker at a speed of 400r / min at a mass ratio of 1:20 , stirred and mixed for 20 minutes to obtain a mixed slurry, then filtered the mixed slurry to obtain coated activated carbon, then placed the coated activated carbon in a tube furnace, and filled the furnace with nitrogen at a rate of 90mL / min, at a temperature of 900°C Under high temperature conditions, react at high temperature for 3 hours to obtain pretreated coated activated carbon, put pretreated coated activated carbon and paraffin in a bal...

example 3

[0024] Add calcium alginate and water into a single-necked flask at a mass ratio of 1:100, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the single-necked flask into a digital speed measuring constant temperature magnetic stirrer at a temperature of 100°C and a speed of Under the condition of 500r / min, heat and stir to dissolve for 50min to obtain calcium alginate liquid; put the waste concrete in a ball mill to pulverize to obtain waste concrete powder; put waste concrete powder and calcium alginate liquid in a mass ratio of 1:50 In the No. 1 beaker, under the condition of rotating speed of 200r / min, stir and mix for 50min to obtain the concrete powder mixture, and then filter the concrete powder mixture to obtain the pretreated waste concrete powder; put the pretreated waste concrete powder in the muffle furnace , at a temperature of 900°C, calcined for 2 hours, and then lowered to room temperature with the furnace to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com