Extremely-low-volatility PAO (polyalpha-olefin) lubricating grease and preparation method thereof

A volatile, lubricating grease technology, applied in the direction of lubricating compositions, petroleum industry, etc., can solve the problems that cannot meet the actual use requirements, and achieve the effect of simple composition, simple process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A very low-volatile PAO grease is prepared from the following raw materials by weight percentage: 60% of PAO after rectification, 39% of PTFE, and 1% of dialkyldiphenylamine.

[0018] It should be noted that in this example, the kinematic viscosity of PAO at 100° C. is 10 mm2 / s, which is composed of a single PAO; the PTFE powder is a single type, with a particle size of about 7 microns.

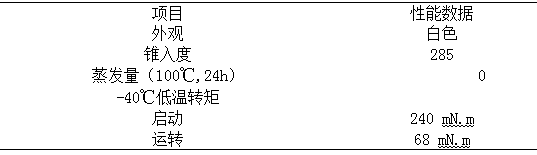

[0019] The performance of the product is shown in Table 1 below:

[0020] Table 1 is the product performance test table of Example 1

[0021]

Embodiment 2

[0023] An extremely low volatility PAO grease is prepared by using the following raw materials by weight percentage: 65% of PAO after rectification, 34.5% of PTFE, and 0.5% of dialkyldiphenylamine.

[0024] It should be noted that in this example, the kinematic viscosity of PAO at 100° C. is 25 mm2 / s, which is composed of two kinds of PAOs; the PTFE powder is a single type, and the particle size is about 4 microns.

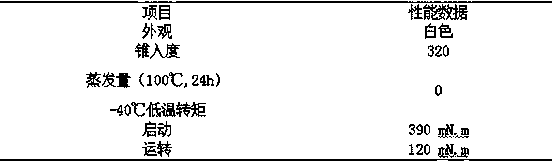

[0025] The performance of the product is shown in Table 2 below:

[0026] Table 2 is the product performance test table of embodiment 2

[0027]

Embodiment 3

[0029] A very low volatility PAO grease, prepared from the following raw materials by weight: 78% PAO after rectification, 21.5% PTFE, 0.5% dialkyldiphenylamine

[0030] It should be noted that in this example, the kinematic viscosity of PAO at 100°C is 36 mm2 / s, which is composed of two kinds of PAOs; the PTFE powder is composed of three different kinds of PTFE, and the particle size is about 4-6 microns.

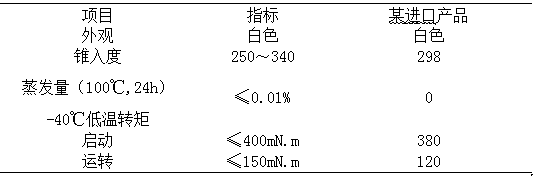

[0031] The performance of the product is shown in Table 3 below:

[0032] Table 3 is the product performance test table of embodiment 3

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com