Air cylinder sleeve for two-stroke diesel engine and processing method for air cylinder sleeve

A technology for a diesel engine and a cylinder liner is applied in the field of cylinder liner for a two-stroke diesel engine, which can solve the problems of abnormal use of the diesel engine, poor cooling effect, blockage of the cooling channel, etc., and achieve the effects of low production cost, strong process operability, and reduced wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

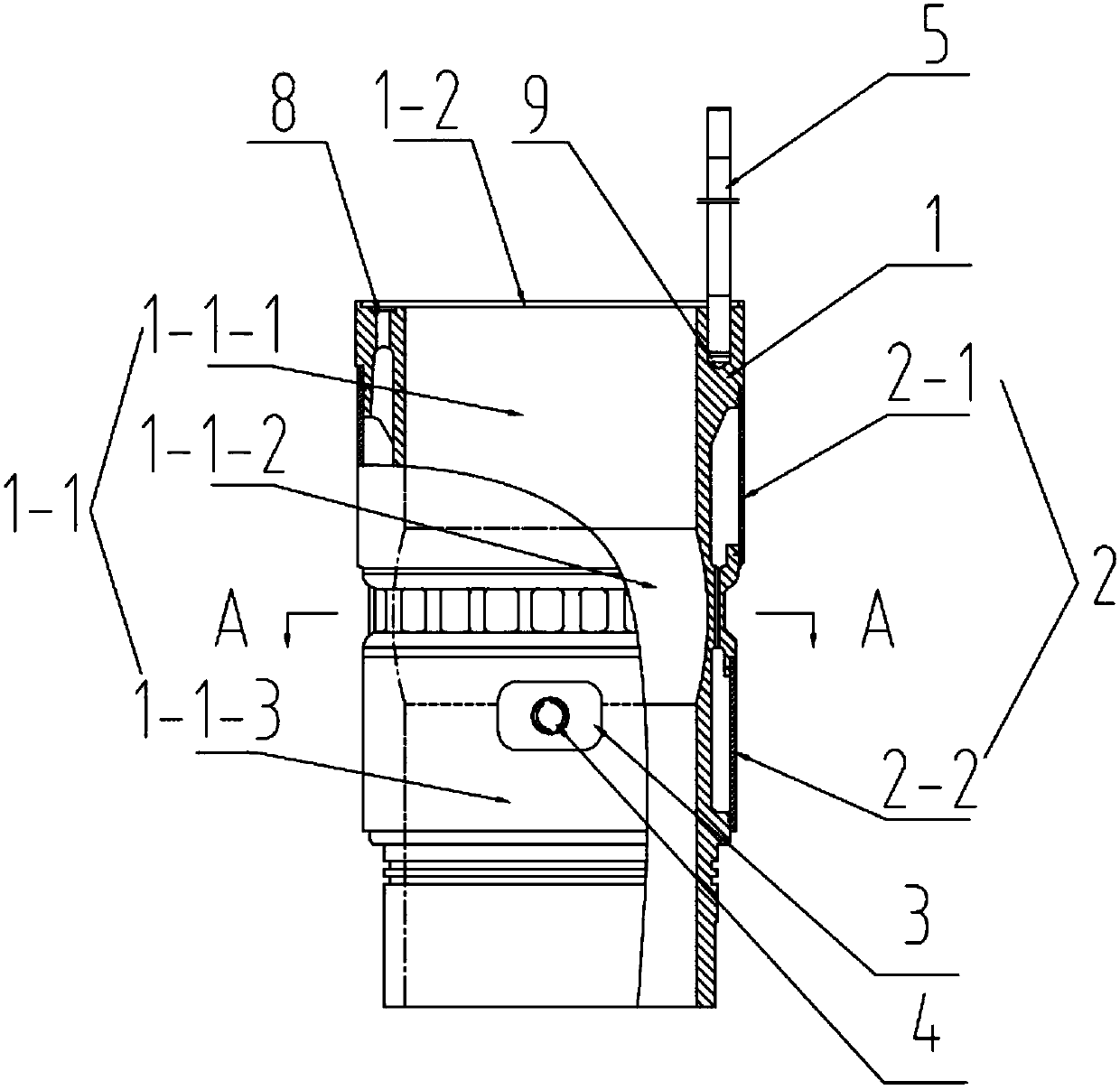

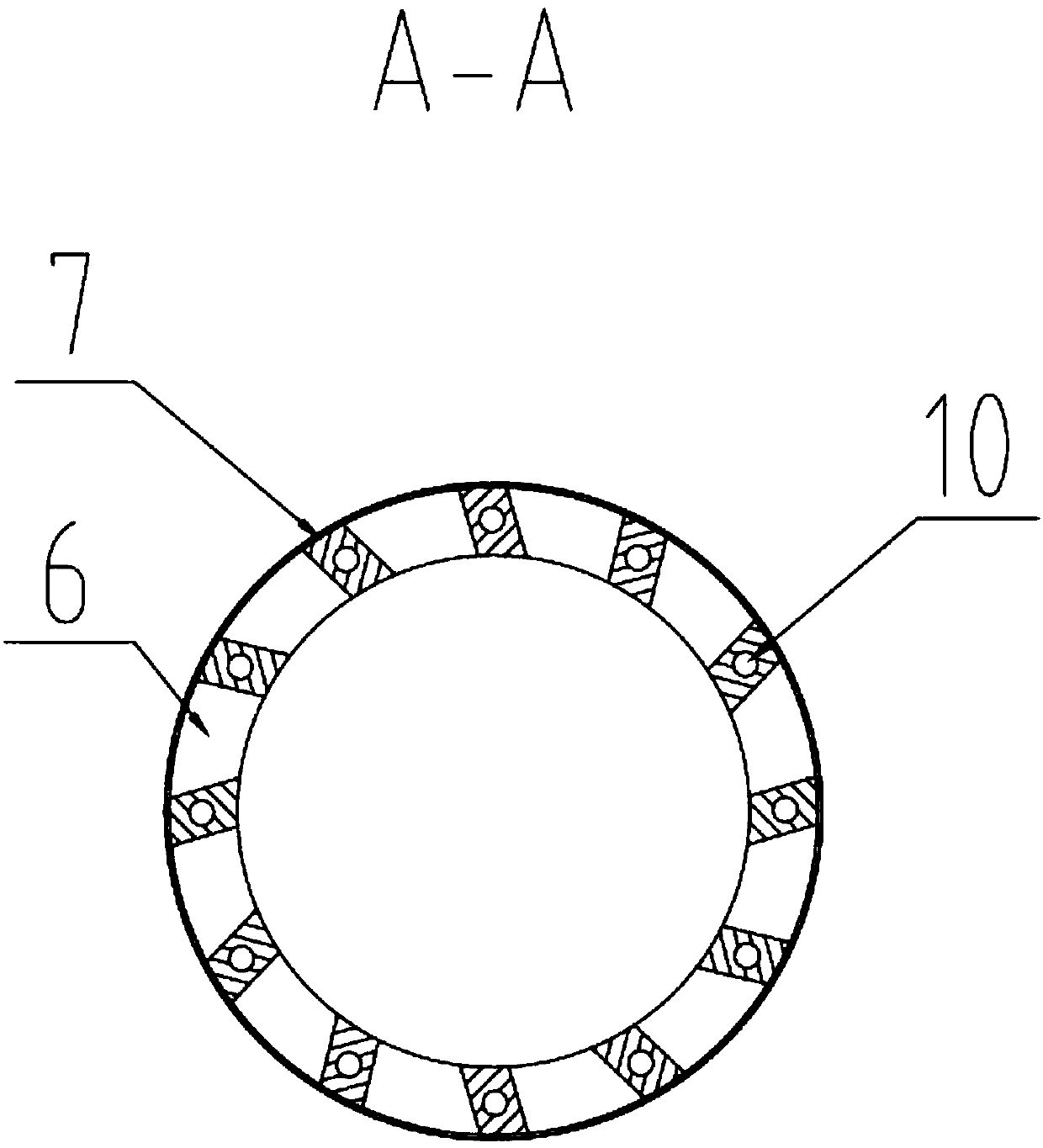

[0037] Such as figure 1 and figure 2 As shown, the cylinder liner for a two-stroke diesel engine of this embodiment includes a cylinder liner body 1, a water jacket 2, a water inlet flange 3, a water separator 4 and a connecting stud 5; the inner hole 1-1 of the cylinder liner body 1 It is divided into upper straight hole section 1-1-1, middle drum shaped hole section 1-1-2 and lower straight hole section 1-1-3 connected up and down; water jacket 2 is upper water jacket 2-1 and lower water jacket 2 -2, respectively brazed on the cylinder liner body 1 to form the upper and lower cooling water chambers; the water inlet flange 3 is welded on the lower water jacket 2-2; the water distributor 4 is made of copper and assembled in the water inlet flange 3 ; The connecting stud 5 is set on the upper end of the cylinder body 1 . The cylinder liner body 1 is provided with 12 scavenging ports 6 and 12 scavenging port columns 7 connecting adjacent scavenging ports 6 at the position cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com