Testing device of shale suction capacity under confining pressure and test method thereof

A testing device and testing method technology, applied in the direction of measuring device, suspension and porous material analysis, instruments, etc., to achieve the effect of increasing volume, improving fracturing effect, and improving the effect of post-fracture stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

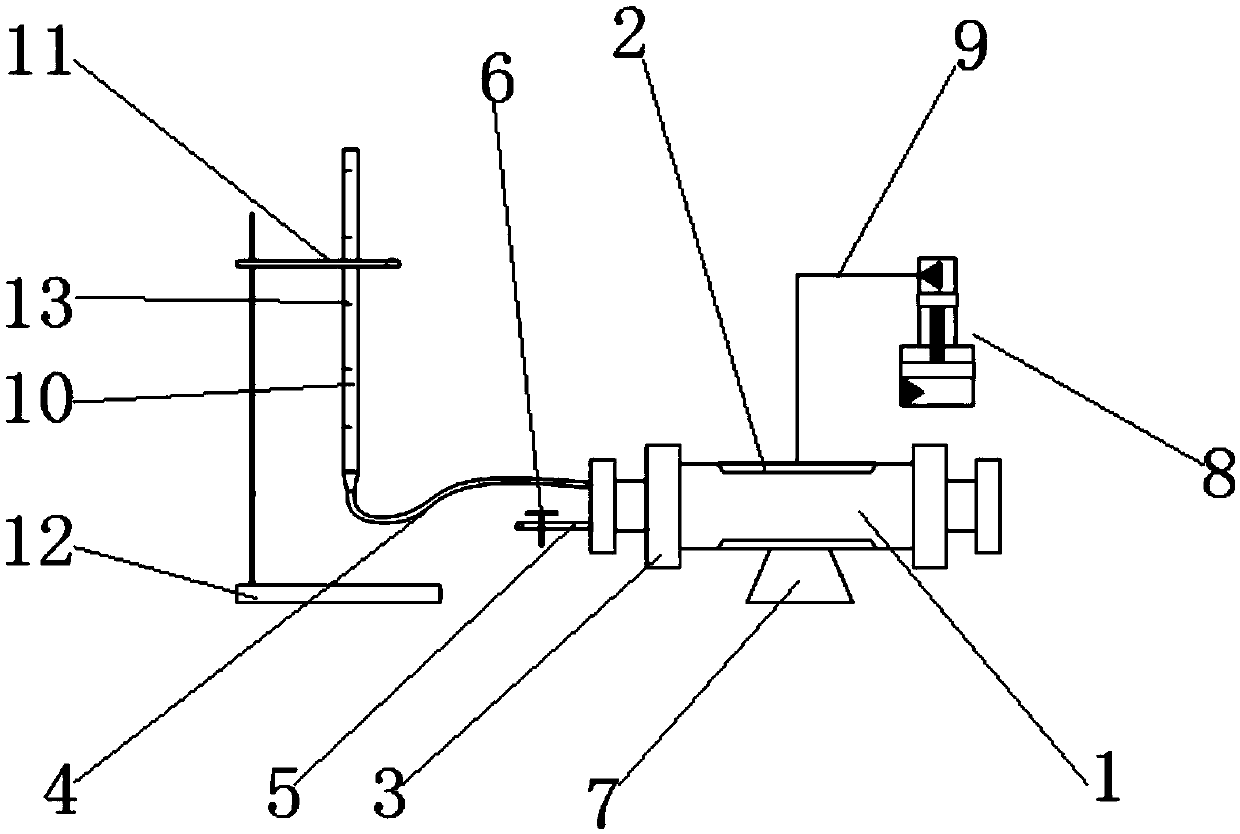

[0028] A test device for shale self-absorption capacity under confining pressure described in this embodiment, such as figure 1 shown, including:

[0029] The formation confining pressure simulation device includes a core holder 2 for clamping the shale rock column 1, a sealing device 3 for sealing both ends of the shale rock column 1, and a confining pressure mechanism connected with the core holder 2 ;

[0030] The liquid supply device includes a metering mechanism connected in series with the sealing device 3 through a hose 4, and a liquid injection pipe 5 connected in series with the sealing device 3 and in parallel with the flexible pipe 4, and the liquid injection pipe 5 is provided with There is a valve 6, and the liquid injection pipe 5 and the metering mechanism are located on the same side of the sealing device 3 .

[0031] When testing, the rock pillar to be tested can be put into the confining pressure device, fixed by the core holder 2, sealed by the sealing dev...

Embodiment 2

[0033] Based on Example 1, such as figure 1 As shown, the bottom of the core holder 2 is also provided with a stand 7 . The confining pressure device can be fixed through the stand 7 while maintaining the level of the shale rock column 1 to reduce test errors.

Embodiment 3

[0035] Based on Example 1, such as figure 1 As shown, the confining pressure mechanism includes a screw pump 8 and a pressurizing pipeline 9 connected to the screw pump 8 , and the pressurizing pipeline 9 is connected to the core holder 2 . Using the screw pump 8 to add confining pressure to the shale rock column 1 can reduce the error of the test result by the confining pressure device and better simulate the real formation pressure environment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com