Method for manufacturing graphite shaft

A graphite shaft and shaft technology, which is applied in the field of manufacturing graphite shafts reinforced at least in part by fillers, can solve the problems of increasing the weight of golf clubs, reducing the weight of golf club heads, destroying balance and the like, and achieving torque reduction, The effect of improved flight distance and directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

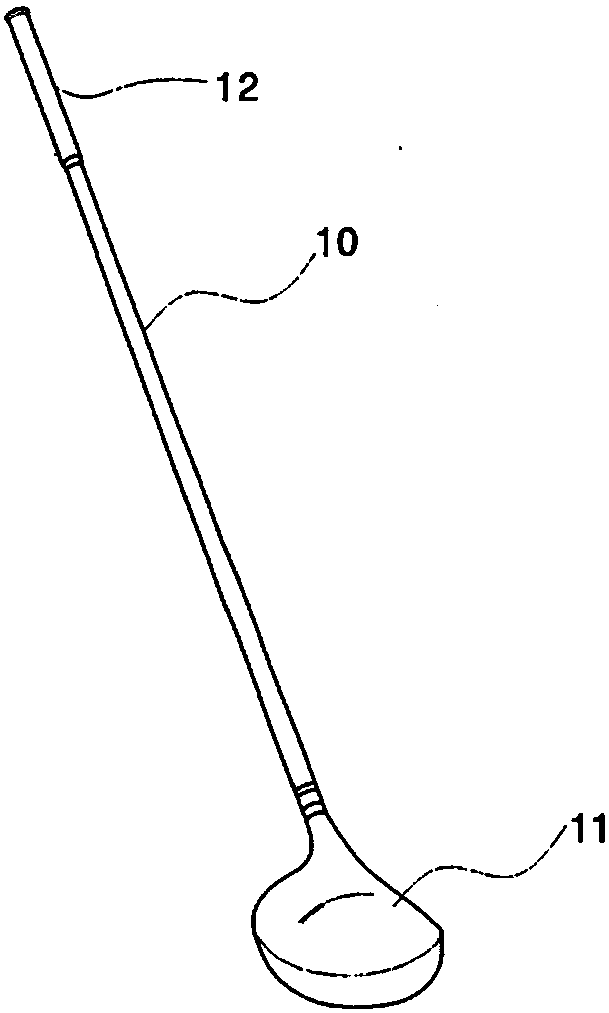

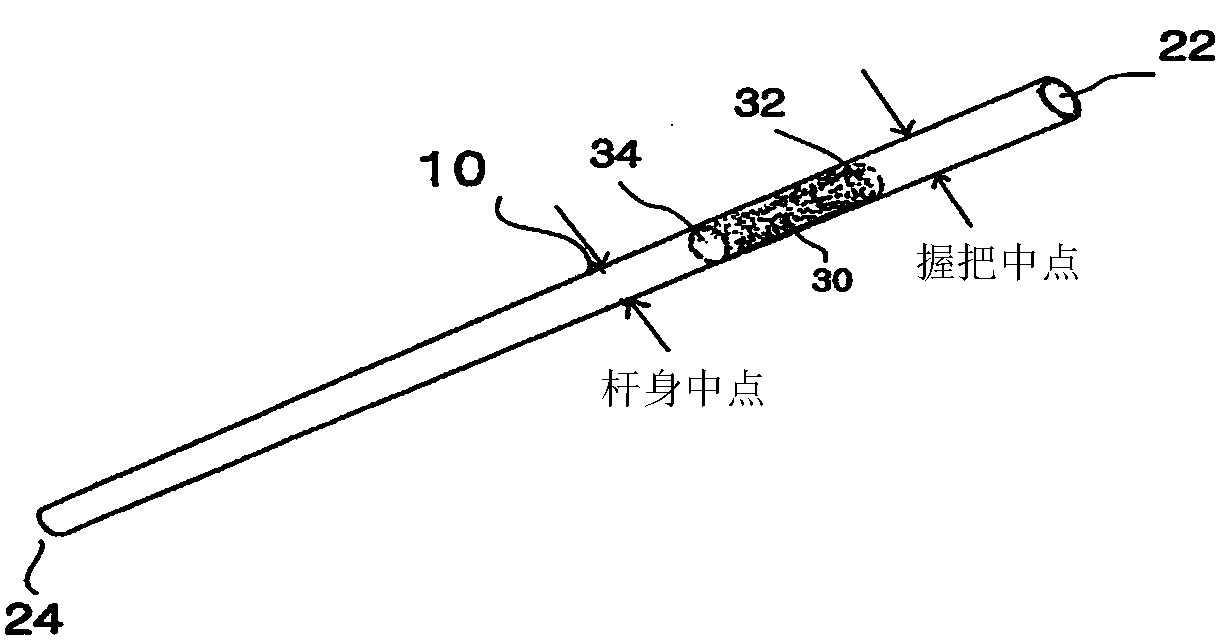

[0035] A method for manufacturing a graphite shaft according to the present invention will be described in detail with reference to the accompanying drawings.

[0036] In the following description, for the sake of simplicity, a method for manufacturing a graphite shaft for golf clubs is described, but it will be apparent to those of ordinary skill in the art that the principles of the present invention should not be limited to golf used with clubs.

[0037] Accordingly, it should be understood that the methods according to the present invention are equally applicable to graphite shafts that may be used with other sporting equipment and everyday items.

[0038] In the following description, the "proximal portion" of the shaft refers to the end portion of the shaft of the golf club or fishing rod where the grip is mounted, ie, the end portion close to the user. Furthermore, the "distal portion" of the shaft is the end portion on the opposite side of the proximal portion, ie the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com