Lubricated automotive vacuum pump

A technology for vacuum pumps and automobiles, applied in the direction of pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problems of non-realization of the opening torque of the check valve, damage, noise of the mechanical check valve, etc., and achieve simple structure, improved fluid dynamics, effects of cost-effective production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

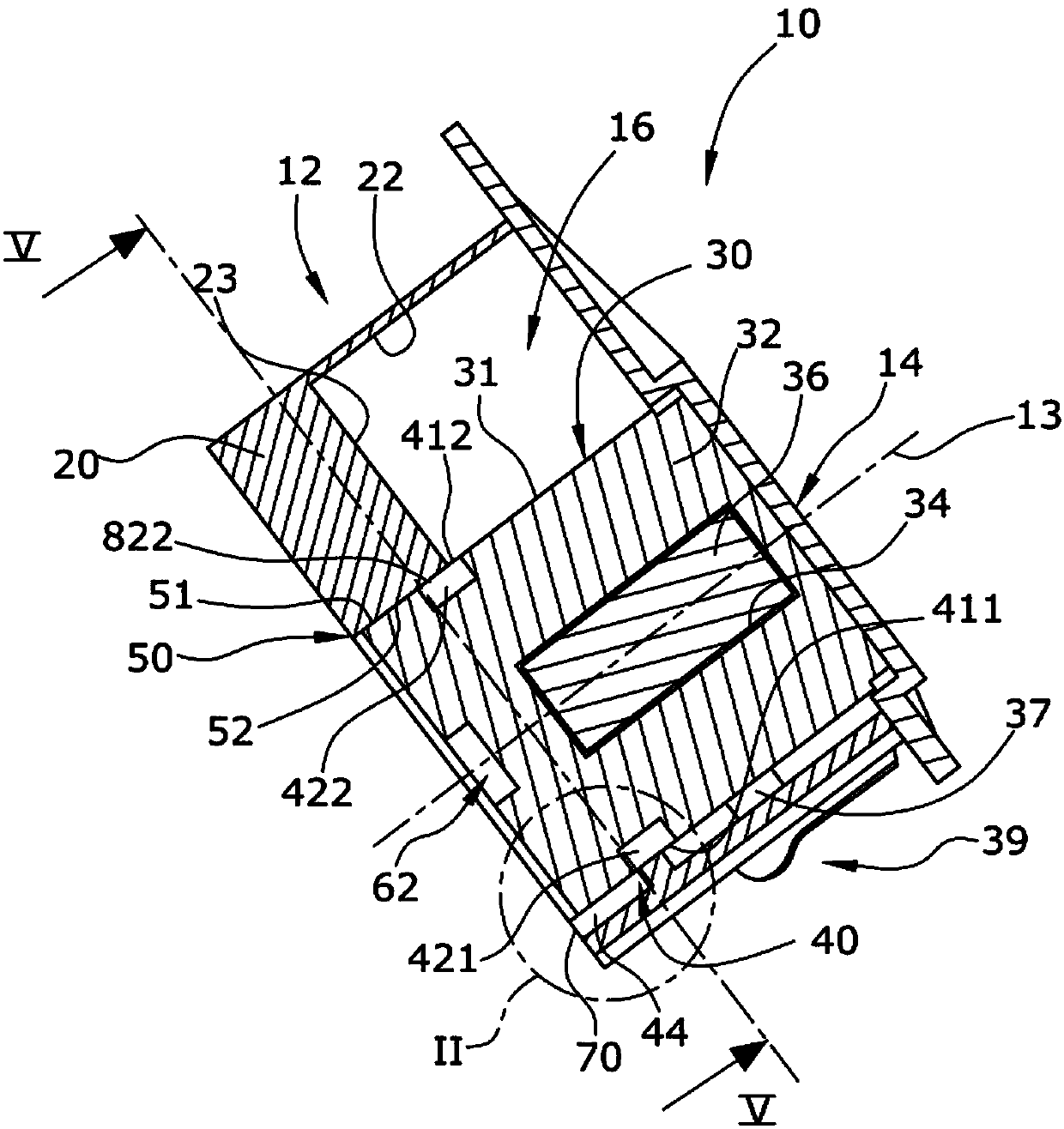

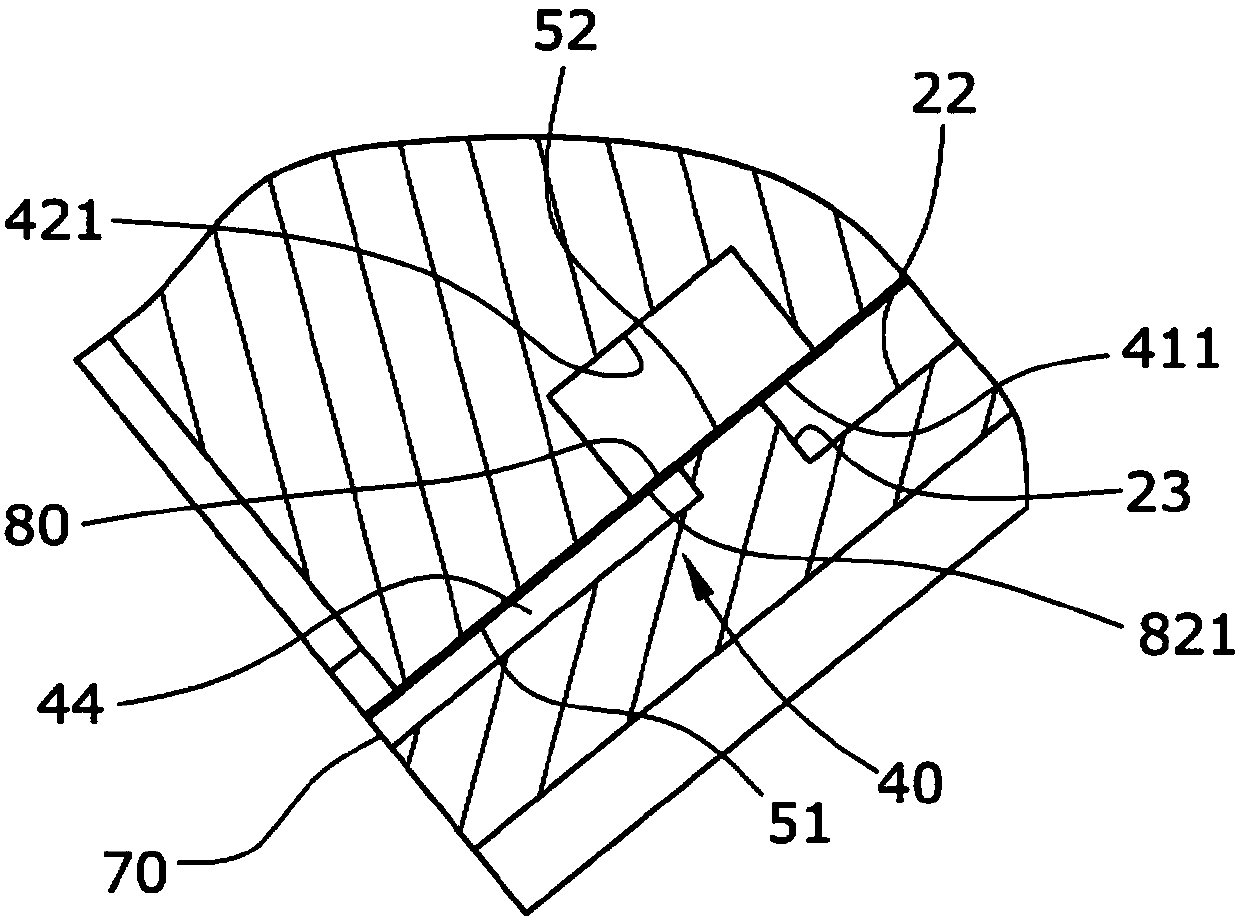

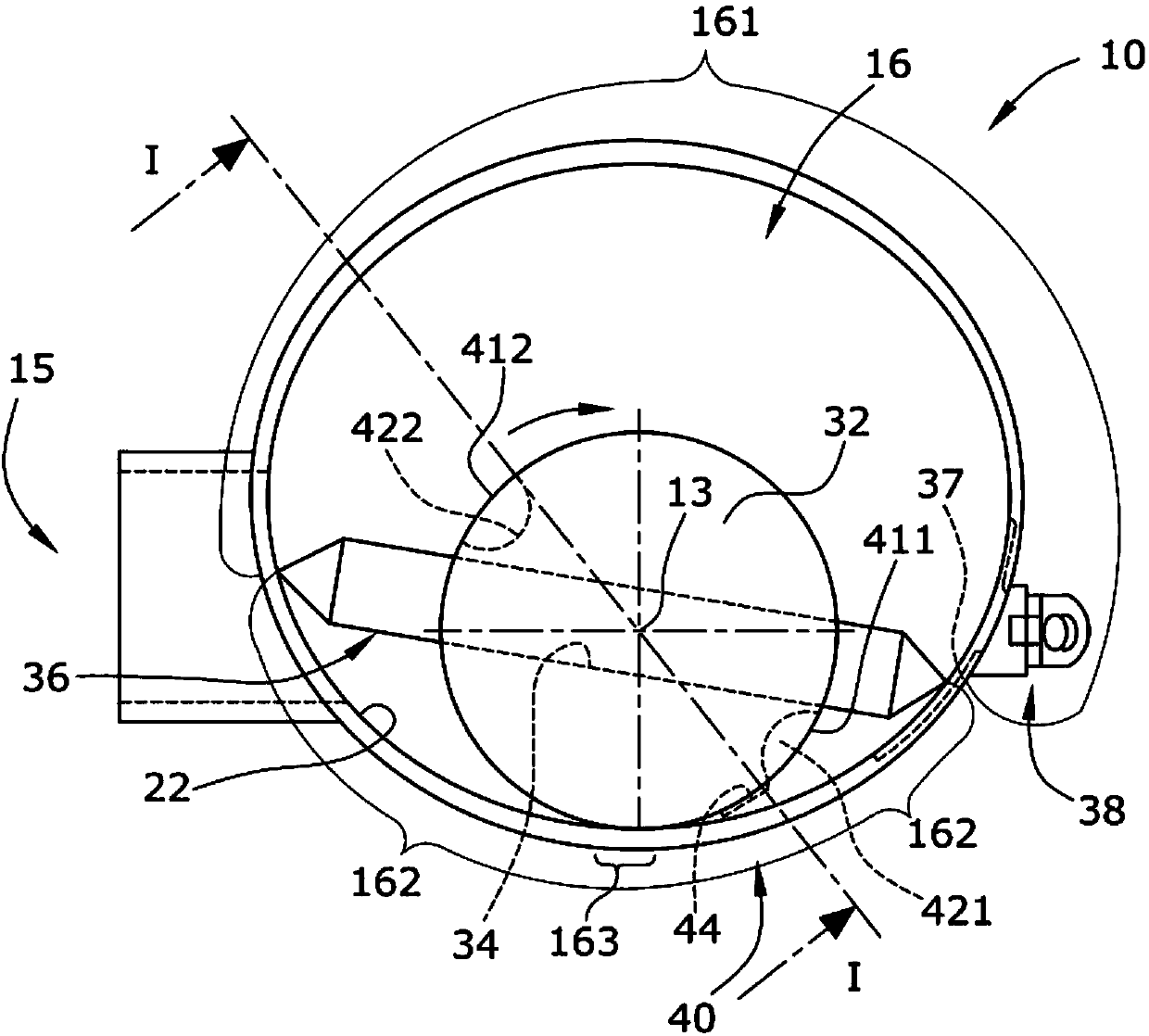

[0025] The drawing shows a lubricated automotive vacuum pump 10 for providing pneumatic low pressure to automotive actuators. The vacuum pump 10 is a mechanical vacuum pump which is mechanically driven by the vehicle engine.

[0026] The vacuum pump 10 is provided with a metallic pump housing 12 substantially defined by two housing parts, namely a pot-shaped outer housing 20 and a cover 14 . The pump housing 12 surrounds the pumping chamber 16 and defines a cylindrical stator friction bearing surface 52 of a rotor friction bearing 50 .

[0027] The vacuum pump 10 is provided with a pump rotor 30 which rotates about an axial axis of rotation 13 . The pump rotor 30 is provided with a cylindrical rotor body 32 provided with radial vane slots 34 supporting vanes 36 movable radially in the vane slots 34 . The rotor body 32 is also provided with a cylindrical rotor friction bearing surface 51 which together with the stator friction bearing surface 52 delimits a friction bearing 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com