Process for non-destructive testing using direct strain imaging

A non-destructive testing and process technology, applied in elastic testing, using stable tension/pressure testing for material strength, fuel testing, etc., can solve problems such as destroying test pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

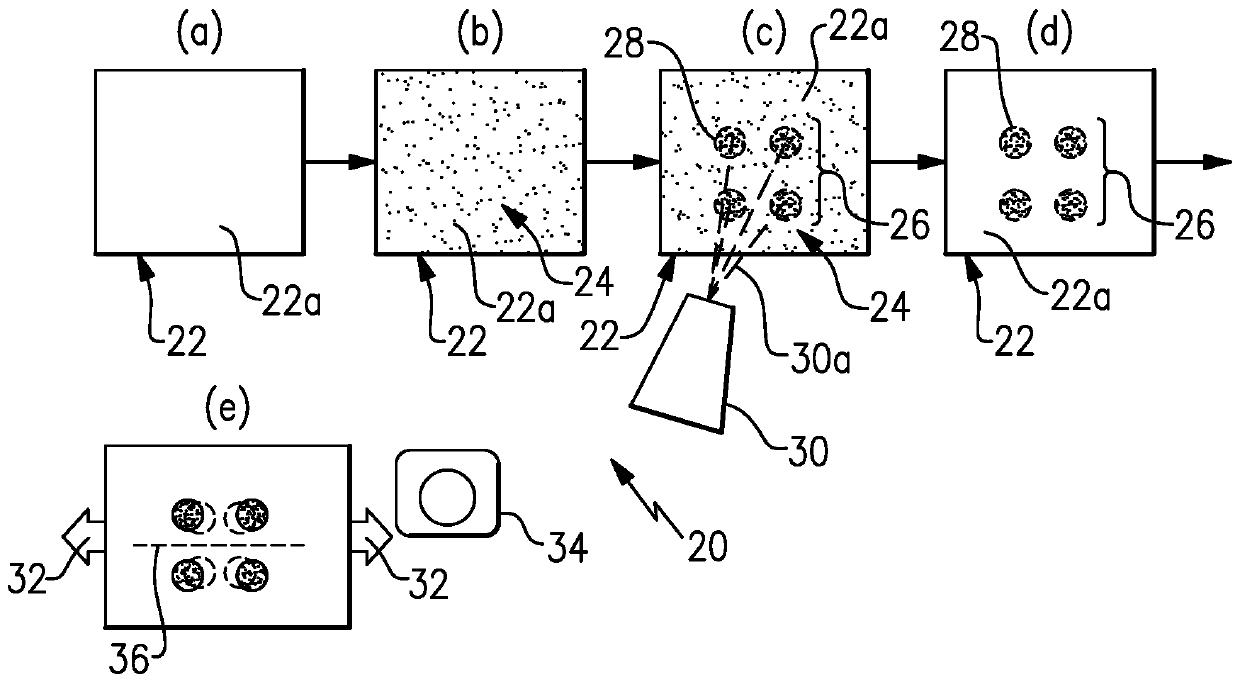

[0026] figure 1 A process 20 for non-destructive testing using direct strain imaging is schematically shown. While basic strain imaging is known, it is currently not suitable for high-volume testing, fabrication or complex geometries. As will be described, process 20 provides the ability to quickly prepare articles for direct strain imaging that are suitable for use with manufactured articles and can be used with articles having complex shapes.

[0027] Process 20 is described with respect to stages (a), (b), (c), (d) and (e), but it is understood that stages may represent combined method operations or may be combined or further subdivided. Phase (a) begins with the item 22 (item body) to be subjected to non-destructive testing. Such non-destructive testing may be performed for a variety of reasons including, but not limited to, quality assurance of manufactured articles, article design evaluation, finite element analysis verification, and article aging effects. Article 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com