Multi-way rubber joint for coffee machine and forming die and demolding method

A technology of rubber joints and forming molds, which is applied in home appliances, kitchen appliances, applications, etc., can solve the problems of large space occupation and increase the cost of coffee machine manufacturing and assembly, and achieve the effect of stable demoulding process, small size and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

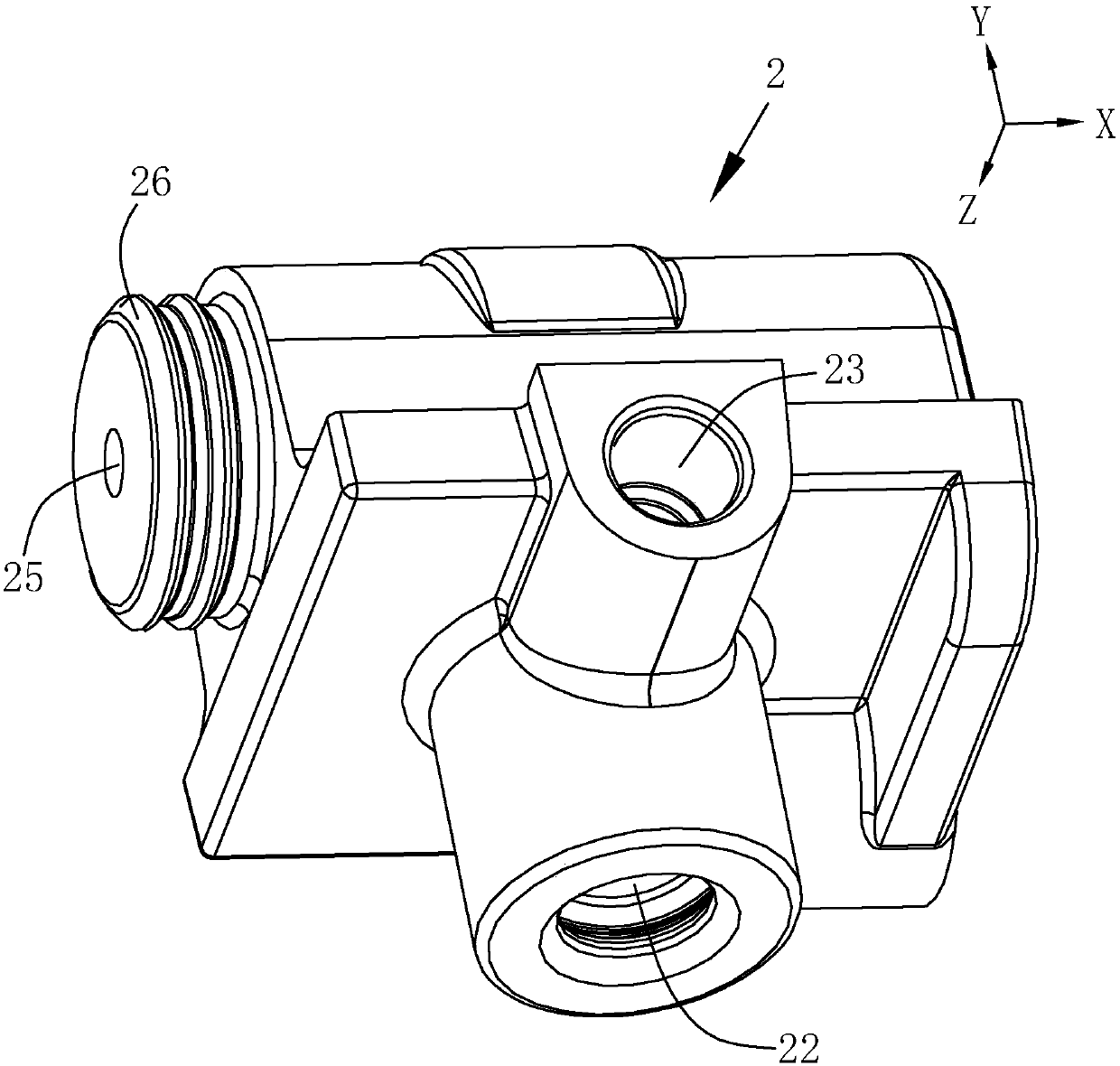

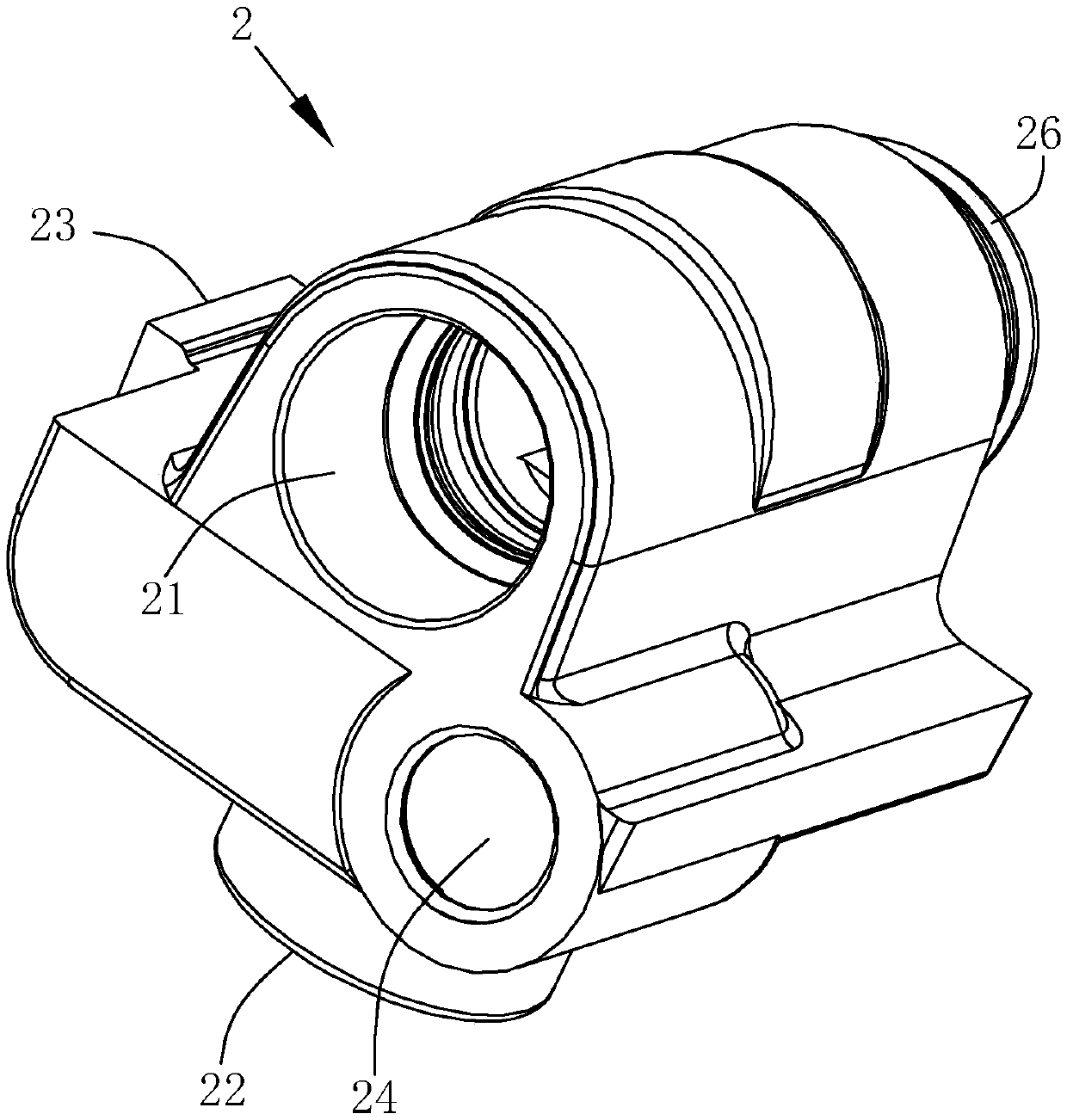

[0055] Embodiment 1: A multi-way rubber joint for a coffee machine, combined with figure 1 and figure 2 As shown, the multi-way rubber joint 2 is integrally injection-molded by rubber materials; the multi-way rubber joint 2 is provided with a first lumen 21 for inputting drinking water, a second lumen 22 for inputting milk liquid, and a second lumen 22 for inputting coffee. The third lumen 23 for liquid, the fourth lumen 24 for introducing air, and the fifth lumen 25 for outputting mixed liquid; the first lumen 21, the second lumen 22, the third lumen 23, The fourth lumen 24 and the fifth lumen 25 communicate directly and / or indirectly.

[0056] The multi-way rubber joint 2 can insert the pipeline for delivering drinking water into the first lumen 21, the pipeline for delivering milk liquid can be inserted into the second lumen 22, the pipeline for delivering coffee liquid can be inserted into the third lumen 23, and the pipeline for delivering coffee liquid can be inserted ...

Embodiment 2

[0062] Embodiment 2: A molding die for a multi-way rubber joint, combined with figure 2 and image 3 As shown, it is used for injection molding the multi-way rubber joint 2 for the coffee machine described in the first embodiment.

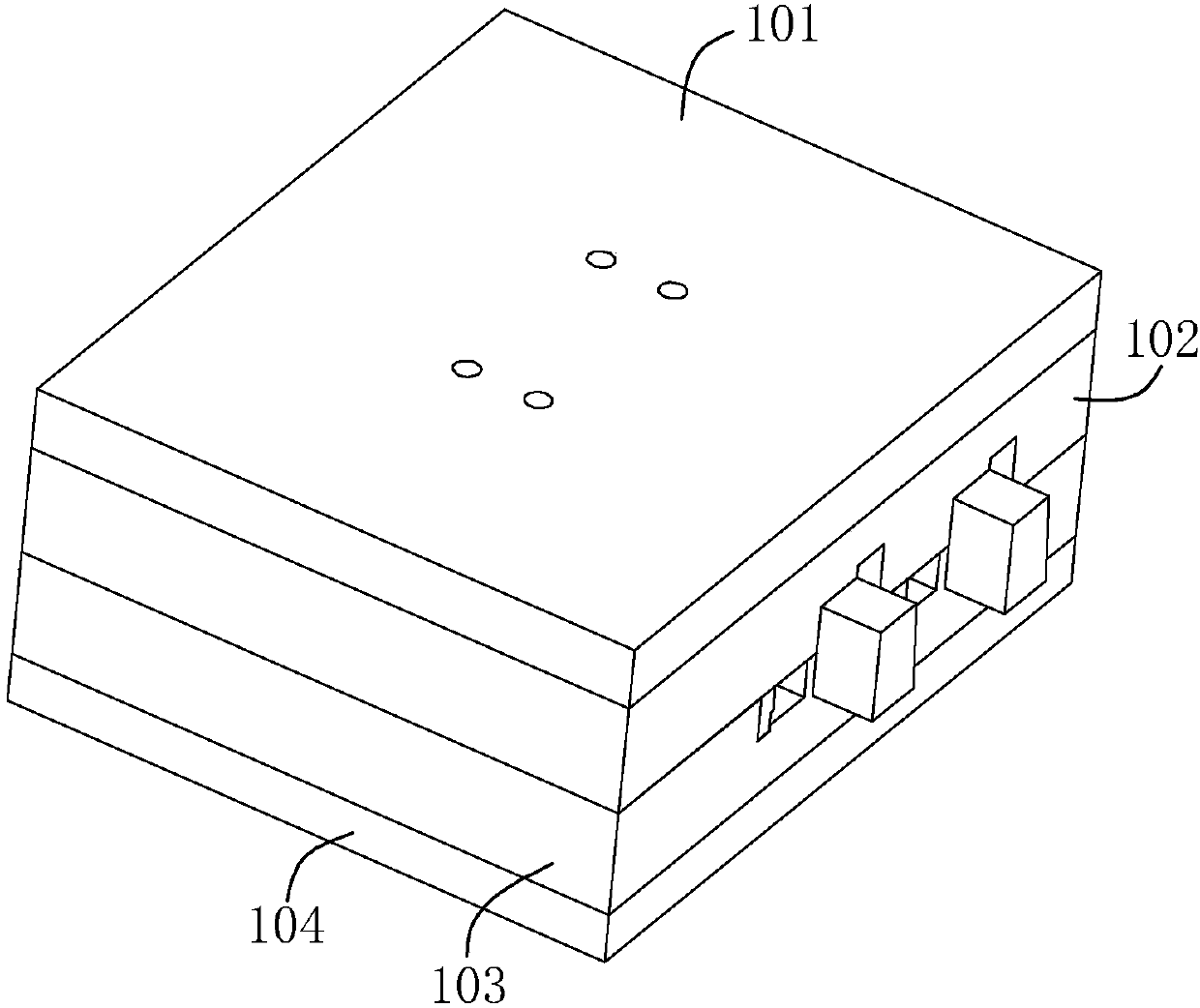

[0063] Such as image 3 As shown, the forming mold includes: an upper mold fixing plate 101 ; an upper mold 102 ; a lower mold fixing plate 104 ; and a lower mold 103 .

[0064] combine Figure 2 to Figure 6 As shown, the molding die also includes: four groups of first sliders 105, four groups of second sliders 106, four groups of second inner cores 107, first inner cores 109, second inner cores 107, third inner cores 108 and The fifth inner core 110 .

[0065] The first slider 105 is slidably assembled on the lower mold 103 along the third direction; the second slider 106 is slidably assembled on the lower mold 103 along the first direction; the second inner core 107 is plug-fitted on the lower mold 103 and Set in two directions, the second ...

Embodiment 3

[0069] Embodiment 3: A molding die for a multi-way rubber joint, the difference from Embodiment 2 is that the combination Figure 7 As shown, the second slider 106 is provided with an assembly groove 1061 in the shape of an inverted T or a dovetail, which is used to assemble the force application member so as to apply force to realize sliding. In the process of demoulding, the second slider needs to be driven 106 slides, because the second slider 106 has a relatively high temperature during the injection molding process, after the assembly groove 1061 is assembled with the force applying part that matches it, it is beneficial for the demoulding personnel to apply force on the second slider 106 with high temperature, Accelerate the demoulding efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com