Mold frame provided with displaceable beating device

A mold base and displacement technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems that cannot be adapted to the processing of fine and diversified metal sheet metal parts, the production cost of turret CNC punching machines is high, and there is no maintenance. Qualification and other issues, to achieve the effect of simple structure, precise movement control, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

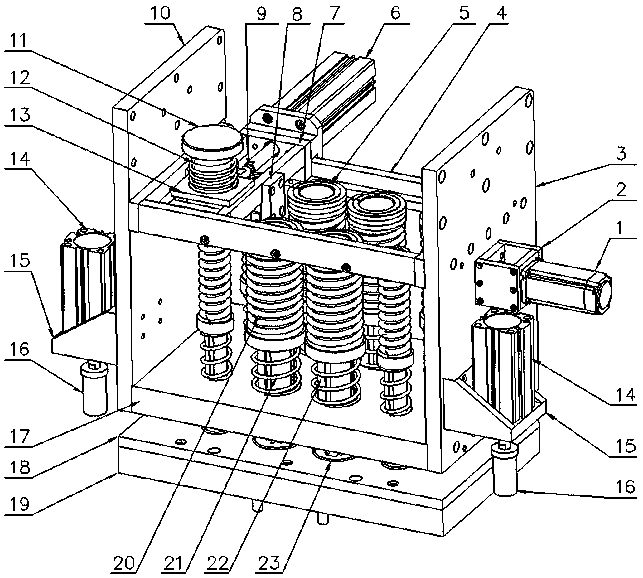

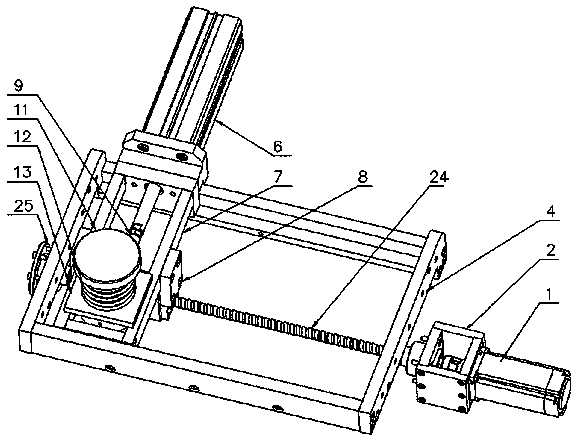

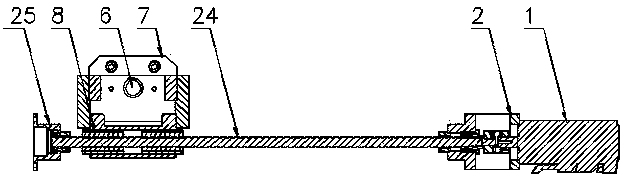

[0020] Figure 1 to Figure 5 As shown, a mold base equipped with a displaceable hitting device is created for the present invention, which includes left and right connecting plates 10, 3, an upper mold fixing plate 17, a lower mold fixing plate 18, a beating mechanism, and an upper mold fixing plate 17. There are punching units with several stations on it, and the lower die fixing plate 18 is provided with a lower die core 23 corresponding to the punching unit. The striking moving frame 7, the striking seat cylinder 6, the striking head 11, the striking return spring 12, the striking seat 13, the left and right connecting plates 10 and 3, the striking fixing frame 4 and the upper die fixing plate 17 are mutually formed and fixed on the punch press. The upper die frame on the frame 32; the striking moving frame 7 is set on the striking fixed frame 4 so as to be movable left and right; the striking seat 13 is set on the striking moving frame 7 so as to be movable back and forth;...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap