Device capable of clearing away drilling winding scraps

A technology for installing grooves and fixing brackets, which is used in drilling/drilling equipment, components of boring machines/drilling machines, metal processing equipment, etc., which can solve the problem of high labor intensity, low processing efficiency of drilling process, and no effective avoidance of iron filings. It can reduce the cost of cutting tools, improve the efficiency of drilling processing, and simplify the manual operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

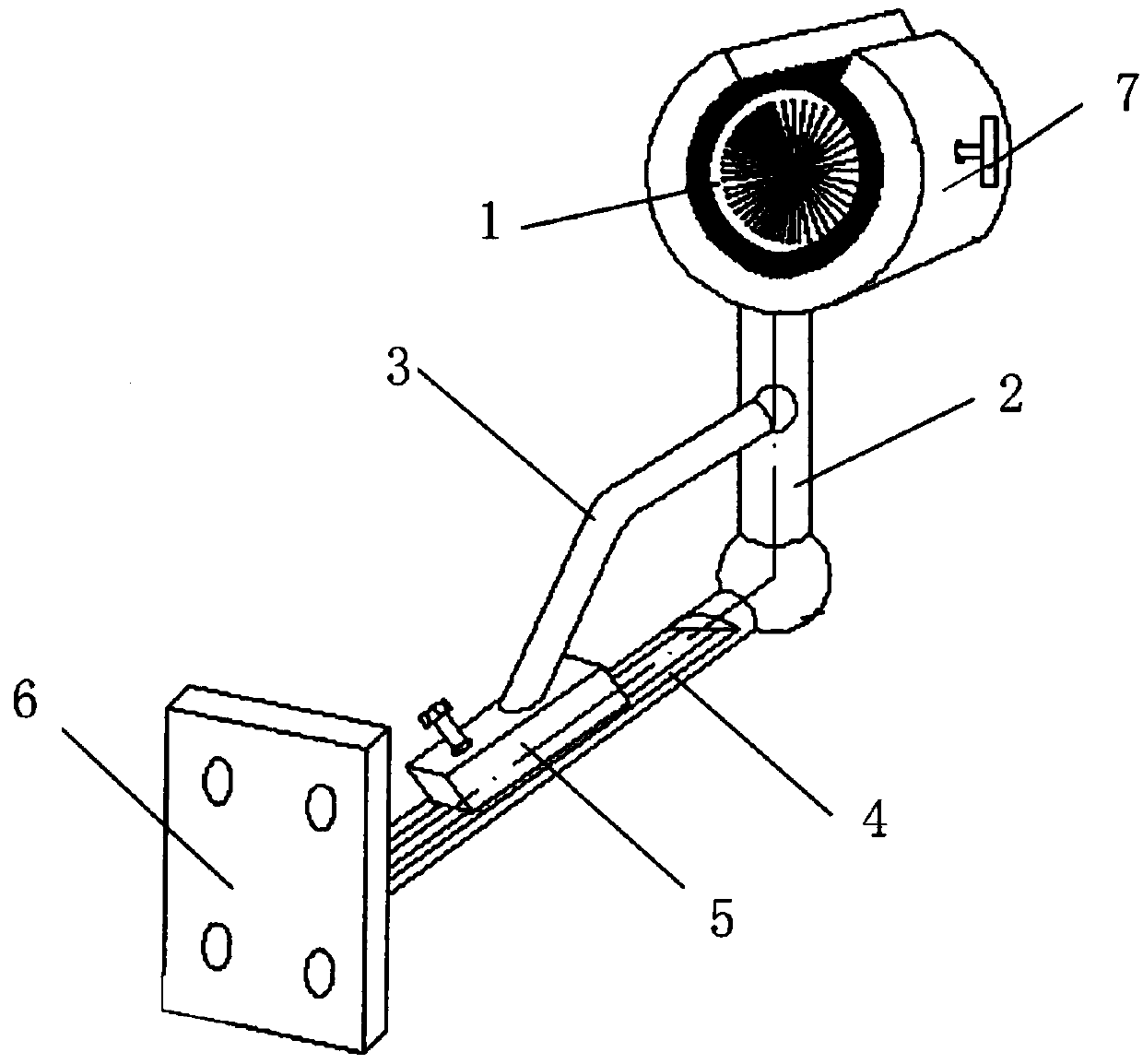

[0017] Such as figure 1 A device capable of cleaning up drilling swarf is shown, including an inner ring brush 1, a fixed bracket 2, a connecting rod 3, a slideway 4, a slider 5 and a base 6;

[0018] The fixed bracket 2 is L-shaped, with an open cylindrical mounting groove 7 at one end, and the other end is fixed on the base 6 by welding;

[0019] The inner ring brush 1 is composed of a cylindrical shell and a wire;

[0020] The metal wires are radially arranged in the casing;

[0021] Place the inner ring brush 1 in the installation groove 7 and fix it with screws;

[0022] The fixed bracket 2 is provided with a slideway 4;

[0023] One end of the connecting rod 3 is connected to the fixed bracket 2, and the other end is connected to the slider 5 and fixed by screws;

[0024] The slider 5 is placed in the slideway 4; the adjustment of the angle of the fixed bracket 2 is realized by adjusting the position of the slider 5 on the slideway 4 to drive the connecting rod 3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com