Tube electrode electroslag welding mould device applicable to steel rails

A technology for welding molds and molds, applied in the direction of rails, auxiliary devices, welding equipment, etc., can solve the problems of large space, position deviation, difficult grinding, etc., to achieve the effect of convenient assembly and fixation, improve work efficiency, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A pipe electrode electroslag welding mold device suitable for rails provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

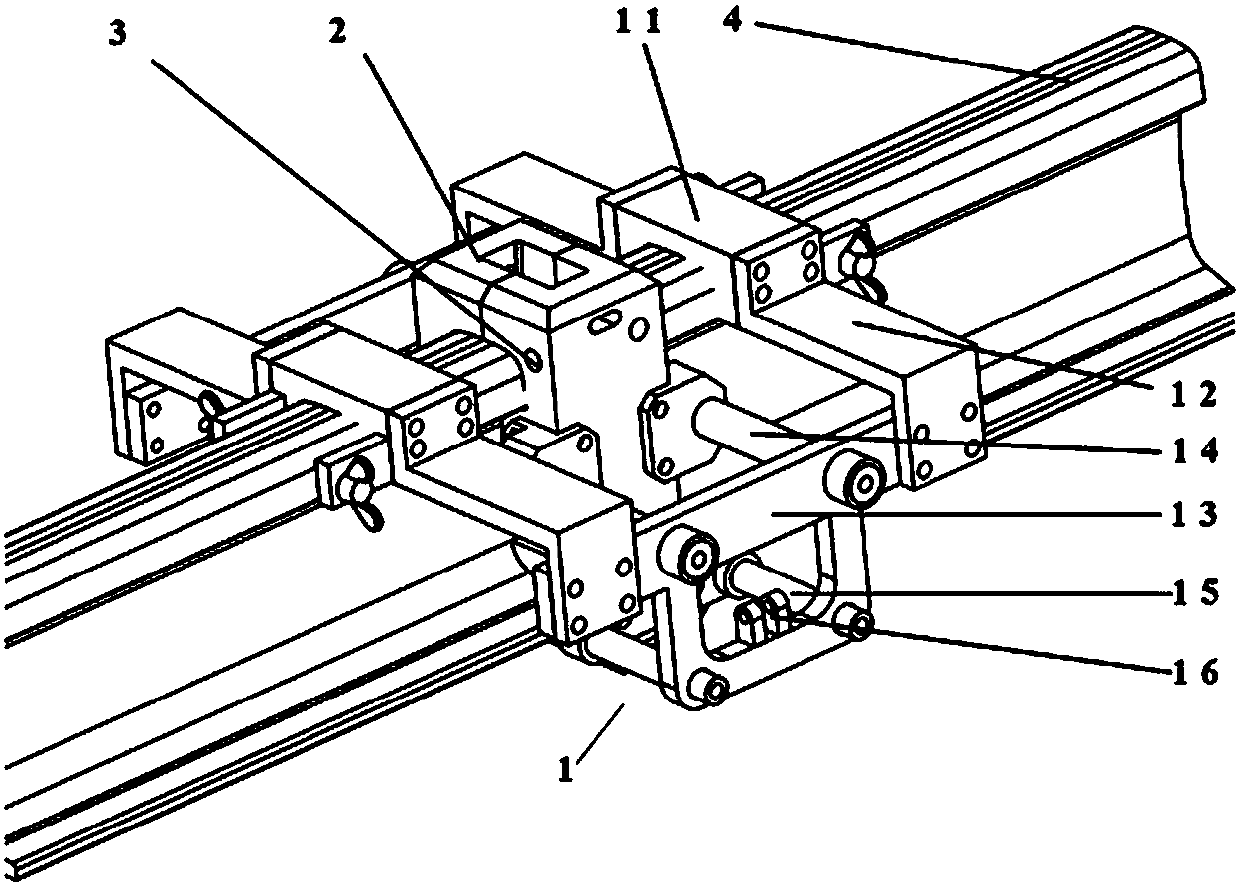

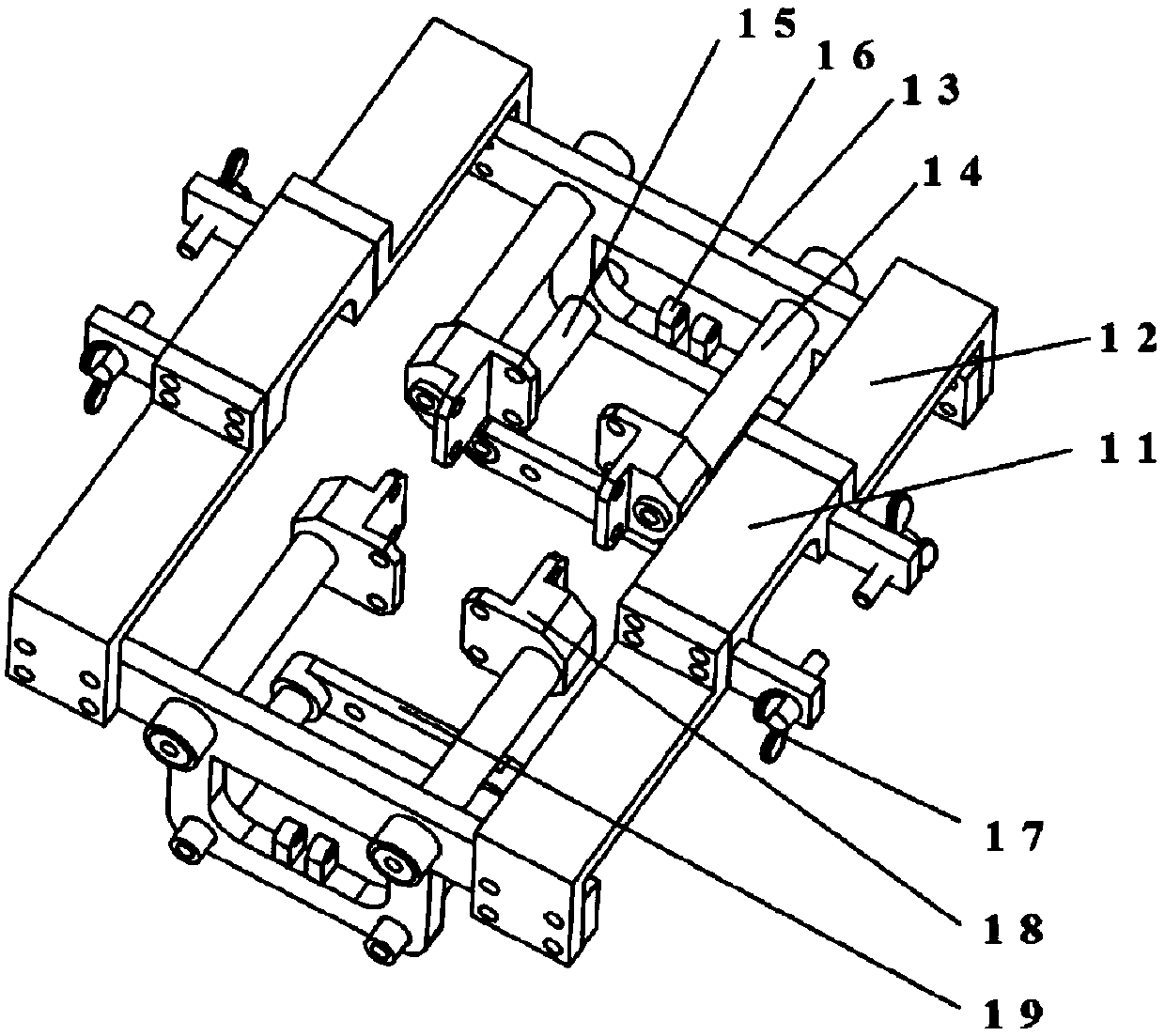

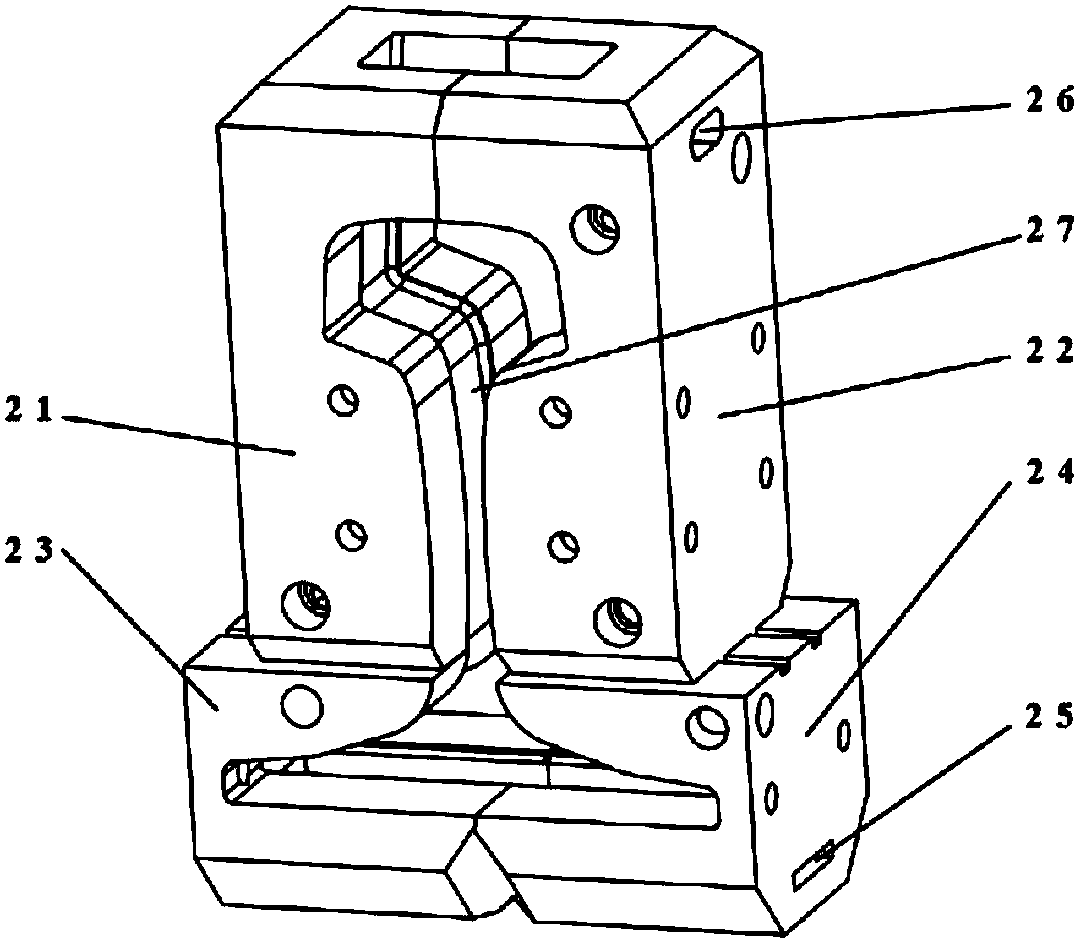

[0024] figure 1 with figure 2 It shows that a tube electrode electroslag welding mold device suitable for rails includes a mold fixing assembly assembly 1, a mold assembly 2 and a cooling cycle assembly 3, and is characterized in that the mold fixing assembly assembly 1 is fixed on On the rail head of the rail 4 to be welded, the mold assembly 2 is arranged in the middle of the mold fixing assembly assembly 1 , and the cooling circulation assembly 3 is arranged inside the mold assembly 2 .

[0025] Mold fixing assembly assembly 1 includes two rail head holding cards 11, four Z-shaped connecting plates 12, two rail waist and rail bottom mold sliding rod fixing support plates 13, four rail waist mold fixing sliding rods 14, and four rail bottom molds The fixed slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com