Defoaming Tray Mold Mechanism

A mold mechanism and tray technology, which is applied in the field of injection molding, can solve the problems of bubbles in the stock solution and uneven flow velocity, and achieve the effect of reducing bubbles and uniform flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below by means of specific embodiments:

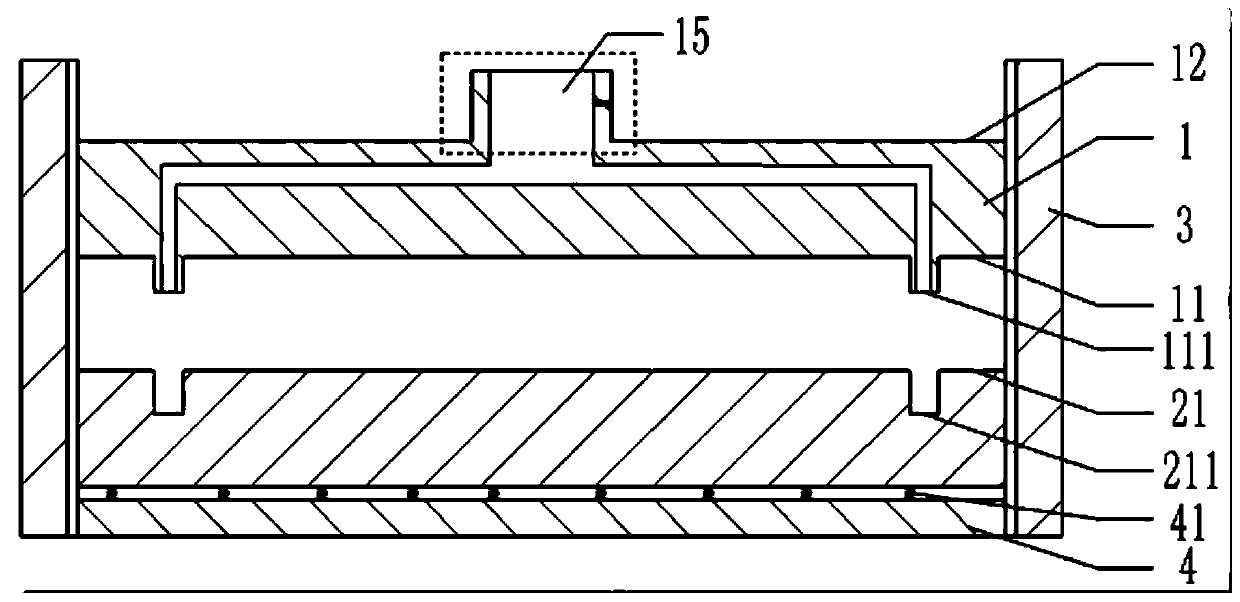

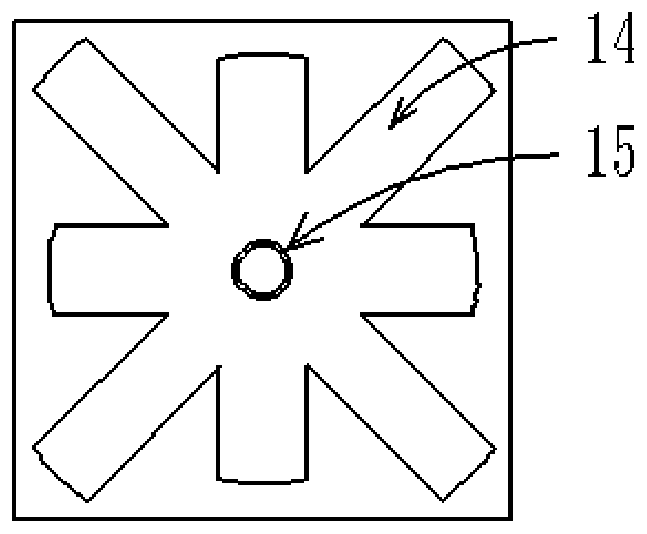

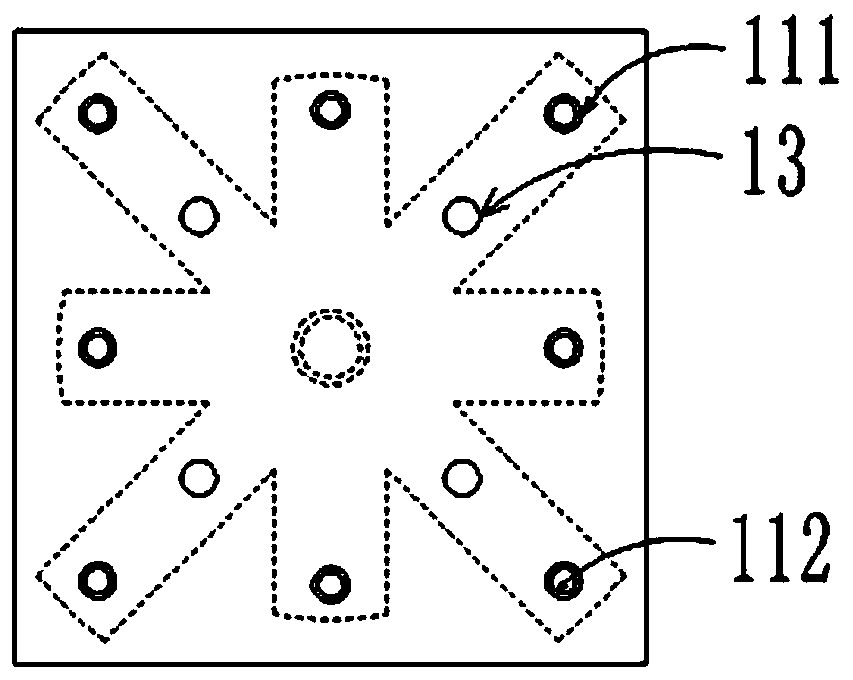

[0036] The reference signs in the drawings of the description include: fixed mold 1, movable mold 2, fixed mold working surface 11, fixed mold injection surface 12, movable mold working surface 21, protruding part 111, protruding gate 112, common gate 13. Recess 211 , feed plate 14 , tubular injection port 15 , slot 16 , reed 17 , limit block 18 , blocking block 19 , limit plate 3 , support plate 4 , and spring 41 .

[0037] Embodiment is shown in accompanying drawing basically:

[0038] The mold mechanism of the defoaming tray of this program includes a support part and a mold part;

[0039] Such as figure 1 , Figure 5 and Figure 6 As shown, the mold part includes a movable mold 2, a fixed mold 1, a reed 17 and a blocking block 19. The upper end surface of the fixed mold 1 is the injection molding surface of the fixed mold, the lower end surface of the fixed mold 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com