High-strength light rotation device

A rotating device, high-strength technology, used in seat arrangement, transportation and packaging, aircraft parts, etc., can solve the problems of low bearing performance and heavy weight, and achieve the effect of reducing weight, simple structure, and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

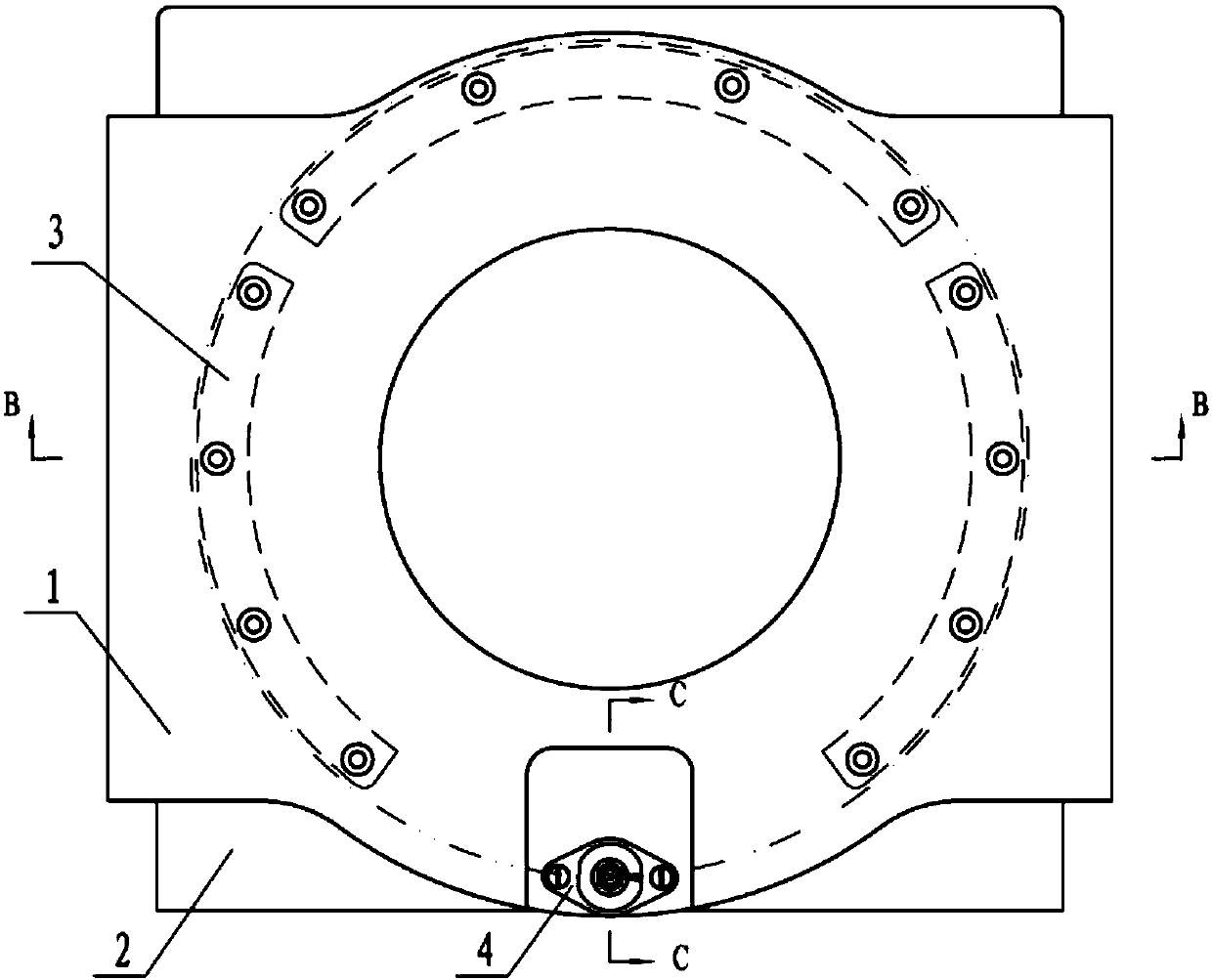

[0020] The rotating device of the present invention includes an upper body 1, a lower body 2, an engaging plate 3, a base 4, a locking pin 5, an upper slide 6, a slide 7, a steel ball 8, a cage 9, a pull ring 10, a compression spring 11, Blocking cover 12, the upper body 1 is connected with the structure that needs to be rotated; the lower body 2 is connected with the product fixing structure, and can also be directly connected with the aircraft floor or bulkhead; the lower end of the upper body 1 and The upper end of the engagement plate 3 is fixedly connected, the lower end of the upper body 1 is fixedly connected with the upper slideway 6 to form a hemispherical slideway 101, and the upper end of the lower body 2 is fixedly connected with the glideway 7 to form a hemispherical slideway 102. The ball 8 is fixed between the upper slideway 6 and the slideway 7 through the round hole 103 of the cage 9, and the "hook" structure 104 of the engaging plate 3 engages in the annular g...

example 2

[0022] The rotating device of the present invention includes an upper body 1, a lower body 2, an engaging plate 3, a base 4, a locking pin 5, an upper slide 6, a slide 7, a steel ball 8, a cage 9, a pull ring 10, a compression spring 11, Blocking cover 12, the upper body 1 is connected with the structure that needs to be rotated; the lower body 2 is connected with the product fixing structure, and can also be directly connected with the aircraft floor or bulkhead; the lower end of the upper body 1 and The upper end of the engaging plate 3 is fixedly connected, the lower end of the upper body 1 is fixedly connected with the upper slideway 6, the upper end of the lower body 2 is fixedly connected with the slideway 7, and the steel ball 8 is fixed on the upper slideway 6 through the round hole 103 of the cage 9 In the middle of the glideway 7, the "hook" structure 104 of the engaging plate 3 engages in the annular groove 105 of the lower body 2 to play the role of rotating guide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com