Inductor package testing method based on inductor package testing equipment

A testing method and testing equipment technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve problems such as difficult discharge of defective products, low pass rate, and unreasonable layout, so as to save energy, improve uniformity, and solve qualified problems. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

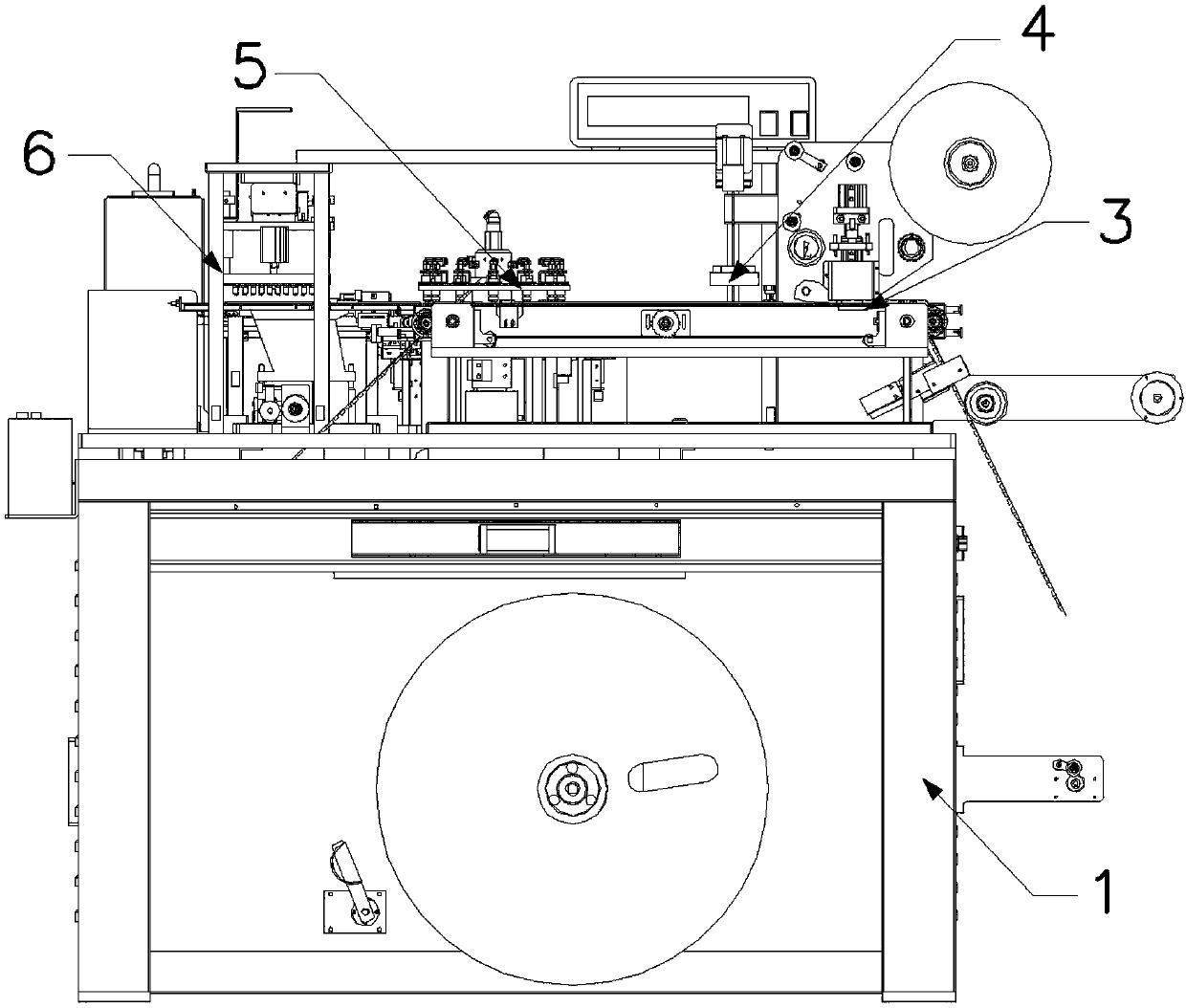

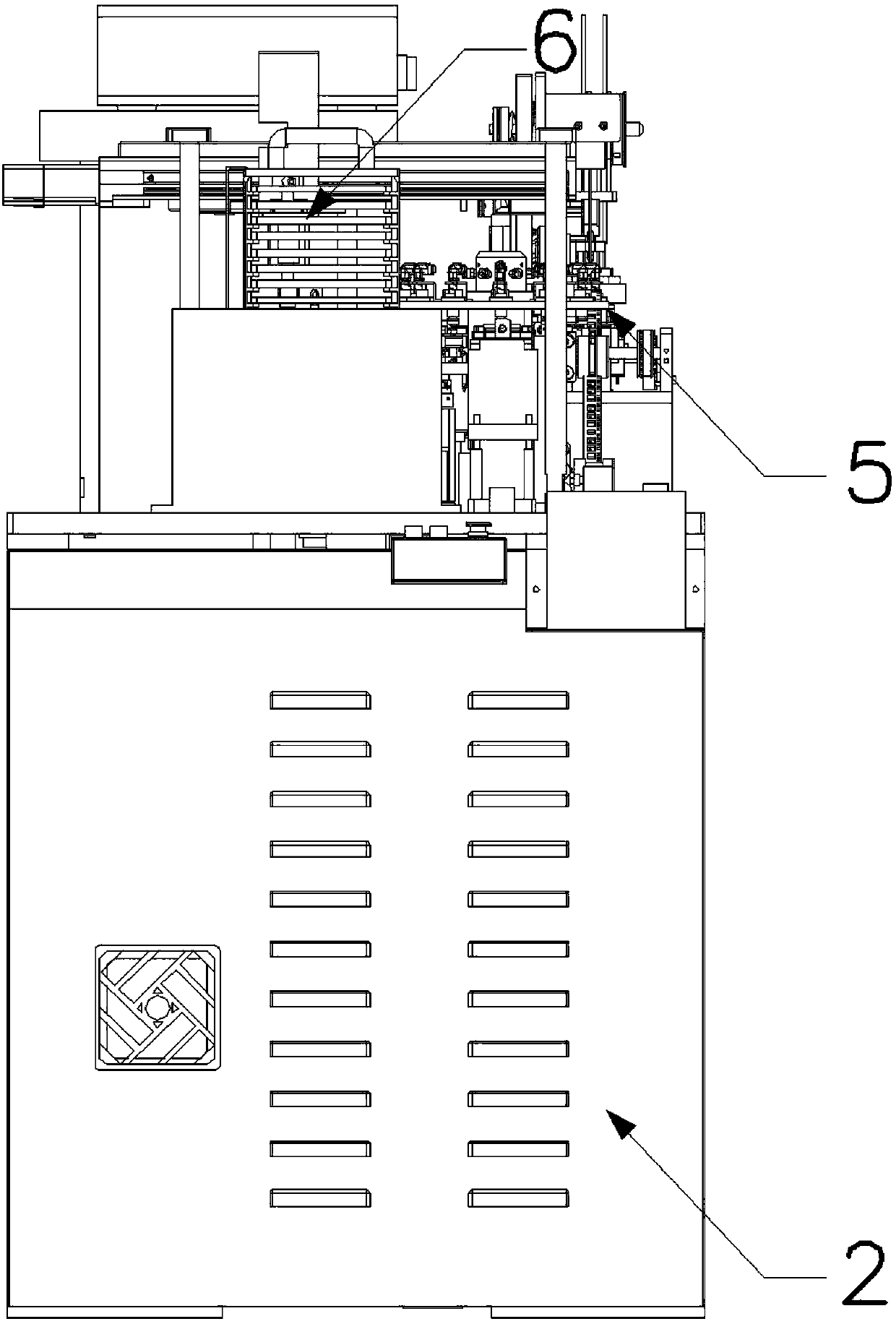

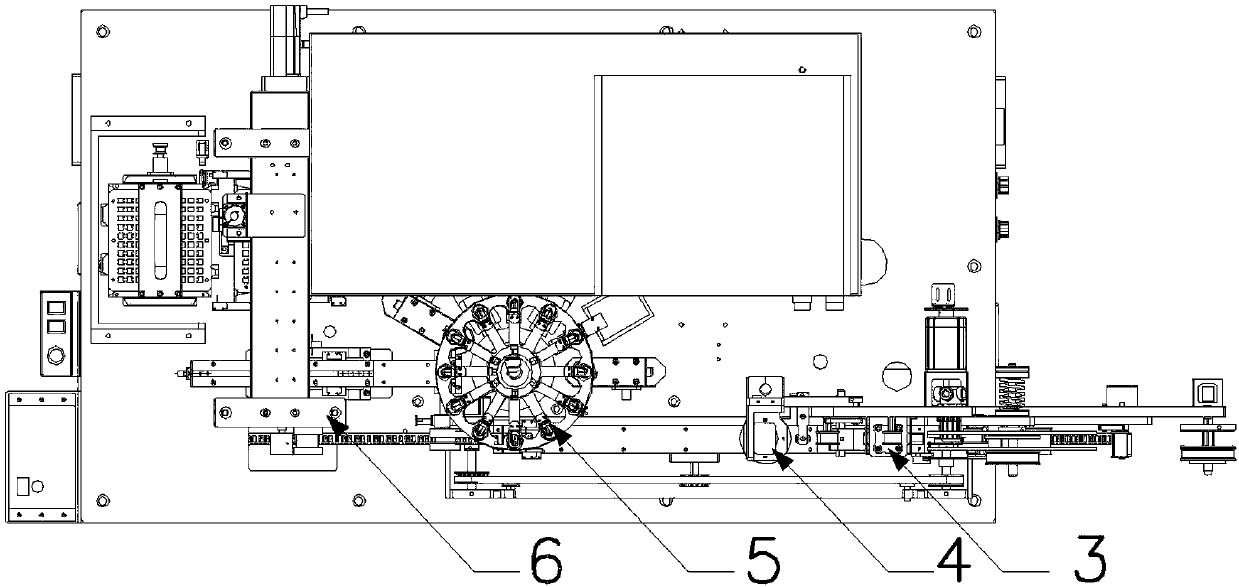

[0055] Example: such as Figure 1-28As shown, the present invention provides a kind of inductance packaging test equipment, comprises frame 1, electrical cabinet 2, packaging mechanism 3, CCD detection mechanism 4, testing mechanism 5 and loading mechanism 6, and electrical cabinet 2 is arranged on the side of frame 1 , the top surface of the frame 1 is provided with an operation panel; the packaging mechanism 3 and the CCD detection mechanism 4 are fixed on the mounting panel of the frame 1 by the bolts at the bottom of the delivery bracket 17, and one end of the delivery bracket 17 is provided with a take-up roller 9, and the take-up roller The roller 9 is fixed on the panel by the fixed shaft 8, and the carrier tape 10 is wound and arranged on the surface of the take-up roller 9, and the carrier tape 10 is connected with the take-up reel 35 after passing through the surface of the transition wheel 11 and the pressure roller 31, and the take-up reel 35 The center is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com